Brother International BAS-411 Rotary Hook Scratches - English

Brother International BAS-411 Manual

|

View all Brother International BAS-411 manuals

Add to My Manuals

Save this manual to your list of manuals |

Brother International BAS-411 manual content summary:

- Brother International BAS-411 | Rotary Hook Scratches - English - Page 1

scratches If you are having problems with thread breaking or fraying on all the needles on a particular head, if multi head machine, then you might have will result in a finish that is not smooth enough for the machine to operate without breaking the thread. Extra fine crocus cloth after the 600-grit

Checking the rotary hook for nicks and scratches

If you are having problems with thread breaking or fraying on all the needles on a

particular head, if multi head machine, then you might have a bad presser foot or it needs

the height adjusted. If changing the presser foot and or height does not fix the problem

than the rotary hook might have some nicks or scratches on it. This is one of the most

common problems and should be checked before adjusting the rotary hook timing. Nicks

and scratches on the rotary hook can be caused by needle breaks and or being careless

when you remove a bird’s nest, i.e. using the tweezers to pull and pry the thread out from

underneath the needle plate.

1.

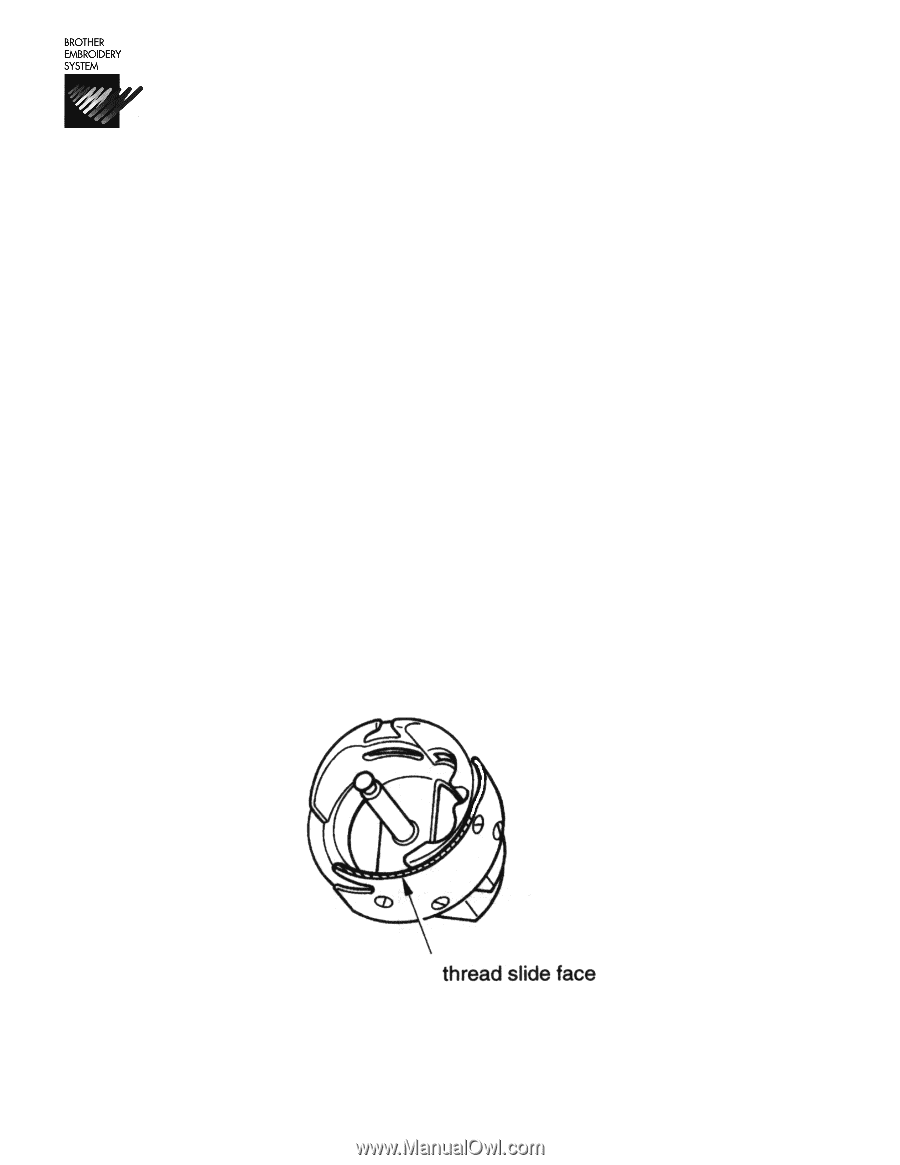

Turn the rotary hook, by either turning the pulley in the back on a 1 and 3 head or

rotating it by hand if on a 4 and 6 head, so that you can inspect the thread slide

face for nicks or scratches (see diagram below).

2.

Feel along the thread slide face to see if it is smooth, free of scratches and nicks.

If you feel any and they aren’t real deep. You might be able to sand or polish the

area until it is smooth. 600 grit sandpaper works well for this. Anything rougher

will result in a finish that is not smooth enough for the machine to operate without

breaking the thread. Extra fine crocus cloth after the 600-grit sandpaper works

well to polish the surface to chrome like finish just like when it was new. Any real

deep gouge or nick you probably won’t be able to sand out so the only option is to

replace the rotary hook.

3.

After checking and repairing the rotary hook it will need to go back to it’s normal

position. This can be done by either turning the pulley in the back on a 1 and 3

head back to 100 degrees or by pressing the back switch on the head on a 4 and 6

head.

A

A

l

l

l

l

M

M

a

a

c

c

h

h

i

i

n

n

e

e

s

s

For Technical Assistance Please Call Toll Free

1-877-4BROTHER