Brother International S-7200B Service Manual - Page 48

REPLACING PARTS, < Timing belt installation check >

|

View all Brother International S-7200B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 48 highlights

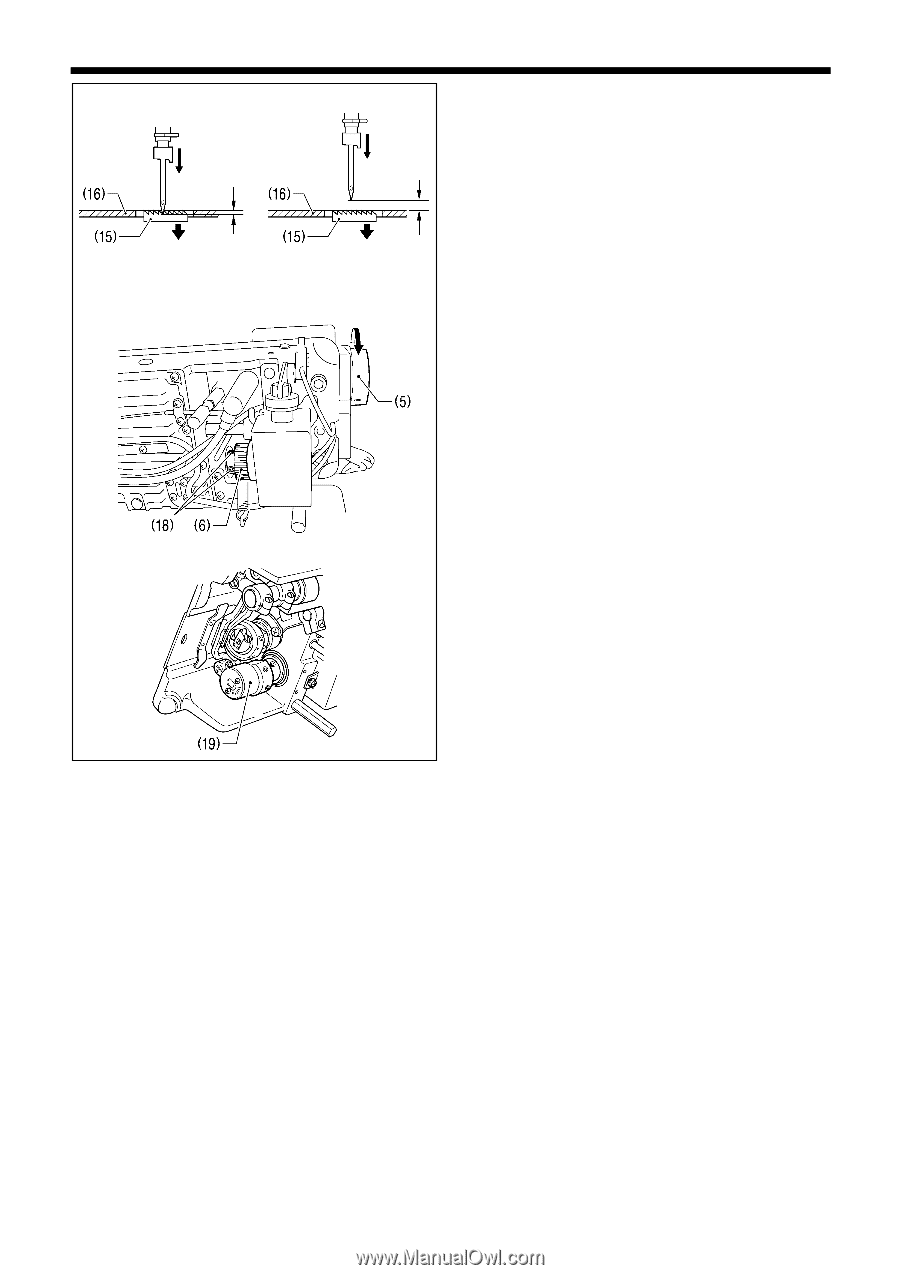

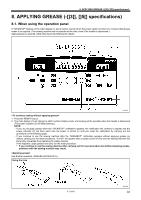

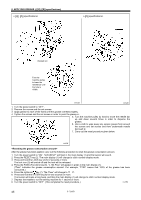

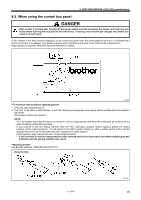

7. REPLACING PARTS Approx. 1mm Approx 3mm < Timing belt installation check > 1. Check that the needle and rotary hook timing is correct. (Refer to "6-10. Adjusting the needle and rotary hook timing".) * If they are correct, continue from step 5, otherwise continue from step 2. 1213B 2. Check that the needle and feed mechanism timing is correct. Turn the machine pulley (5) forward to lower the feed dog (15) from its highest position until it is aligned with the top of the needle plate (16), and check that the tip of the needle is at the following position at this time. The top of the feed dog (15) and the top of the needle plate (16) should be aligned, and the point of the needle should be approximately 1 mm below the needle plate (16). The top of the feed dog (15) and the top of the needle plate (16) should be aligned, and there should be a clearance of approximately 3 mm between the point of the needle and the needle plate (16). 1215B * If it is not in the correct position, carry out the following steps. 1) Tilt back the machine head, and then loosen the two set screws (18). 2) Turn timing pulley D (6) forward to lower the feed dog (15) until it is at the same height as the needle plate (16). 3) While holding the vertical cam (19) with one hand so that it will not move, turn the machine pulley (5) forward to lower the needle to the correct position. 4) Tighten the two set screws (18). 1216B 3. Adjust the needle and rotary hook timing so that it is correct. (Refer to "6-10. Adjusting the needle and rotary hook timing".) 4. Check that the thread trimming timing is correct. If it is not correct, adjust it by following the adjustment procedure. (Refer to "6-11. Adjusting the thread trimming timing".) 5. Set the sewing machine to needle up stopping, and then operate the sewing machine and let it stop. Check that the reference line (d) on the machine pulley (5) is within the range of the mark (e) on the motor cover (3) at this time. 41 S-7200B