Brother International S-7200B Service Manual - Page 7

Contents

|

View all Brother International S-7200B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

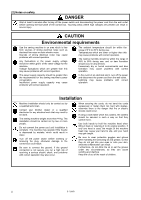

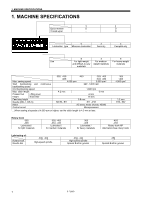

CONTENTS 1. MACHINE SPECIFICATIONS 1 2. NOTES ON HANDLING 2 3. FUNCTION SETTINGS (OPERATION PANEL 3 3-1. Maximum sewing speed and start backtack sewing speed setting methods 3 3-2. Using the LOCK key 4 3-3. Setting the DIP switches 4 3-4. Setting functions 5 3-5. Function List 6 3-6. Clearing saved data (Initialization 21 4. INITIALIZING THE CONTROL BOX PANEL 22 5. ADJUSTING THE ROTARY HOOK LUBRICATION AMOUNT (-[]0[], []3[] specifications 23 6. ADJUSTMENTS 24 6-1. Adjusting the actuator position 24 6-2. Adjusting the safety switch position 25 6-3. Adjusting the thread take-up spring 26 6-4. Adjusting arm thread guide R 27 6-5. Adjusting the presser foot height 27 6-6. Adjusting of the feed dog height 28 6-7. Adjusting the feed dog angle 29 6-8. Adjusting the needle bar height 30 6-9. Adjusting the needle and feed mechanism timing.... 30 6-10. Adjusting the needle and rotary hook timing .......... 31 6-11. Adjusting the thread trimming timing 32 6-12. Adjusting the thread take-up amount (-[][]3 specifications 33 6-13. Adjusting the needle up stop position (When using the operation panel 34 6-14. Setting the needle up stop position and needle down stop position (If using the control box panel 35 6-15. Adjusting the treadle 37 6-16. Adjusting the presser foot floating amount (minute lifting amount 37 7. REPLACING PARTS 38 7-1. Fixed knife 38 7-2. Movable knife 38 7-3. Motor and timing belt 39 7-4. Rotary hook RP 42 7-5. Feed bar shaft, Lifting feed shaft 43 8. APPLYING GREASE (-[]3[], []5[] specifications 44 8-1. When using the operation panel 44 8-2. When using the control box panel 46 9. CONTROL SYSTEM 48 10. CONTROL BOX AND MOTOR...........49 10-1. Removing and installing the control box 49 10-2. Control box and motor rating plate 50 10-3. Control circuit board 52 10-4. Checking the motor and power supply 54 10-5. Checking the solenoids 55 11. TREADLE UNIT ASSEMBLY 56 11-1. Types 56 11-2. Standard setting values 57 11-3. Setting method for standard depression strokes 58 12. STANDING OPERATION PEDAL ......62 12-1. Installing the foot plug 62 12-2. Connectors 63 13. TROUBLESHOOTING 64 13-1. Sewing 64 13-2. Error code displays 69 14. SEGMENT DISPLAY DEFINITION TABLE 74 S-7200B