Brother International S-7200B Service Manual - Page 72

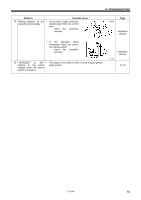

TROUBLESHOOTING, Problem, Possible cause, Is the bobbin scratched?

|

View all Brother International S-7200B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 72 highlights

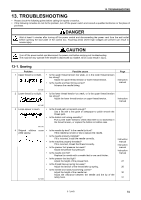

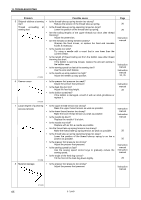

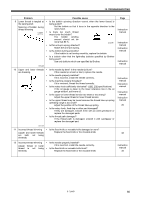

13. TROUBLESHOOTING Problem 5 Skipped stitches at sewing start Thread unravelling at sewing start 6 Uneven seam 0749M 0473M 7 Large degree of puckering (excess tension) 8 Material slippage 0978M Possible cause Is the thread take-up spring tension too strong? Reduce the tension of the thread take-up spring. Is the thread take-up spring operating range too large? Lower the position of the thread take-up spring. Are the trailing lengths of the upper threads too short after thread trimming? Adjust the pretension. Are the threads not being trimmed cleanly? Sharpen the fixed knives, or replace the fixed and movable knives if necessary. Is the needle too wide? Try using a needle with a count that is one lower than the current needle. Is the length of thread trailing out from the bobbin case after thread trimming too short. If the bobbin is spinning loosely, replace the anti-spin spring in the bobbin case. Is the sewing speed too fast at the sewing start? Use the slow start feature. Is the needle up stop position too high? Adjust the needle up stop position. Page 26 26 Instruction manual Instruction manual Instruction manual 34, 35 Is the presser foot pressure too weak? Adjust the presser foot pressure. Is the feed dog too low? Adjust the feed dog height. Is the bobbin scratched? If the bobbin is damaged, smooth it with an oiled grindstone or replace it. Instruction manual 28 Is the upper thread tension too strong? Make the upper thread tension as weak as possible. Is the lower thread tension too strong? Make the lower thread tension as weak as possible. Is the needle tip blunt? Replace the needle if it is blunt. Is the needle too thick? Replace with as thin a needle as possible. Are the thread take-up spring tensions too strong? Make the thread take-up spring tension as weak as possible. Is the thread take-up spring operating range too large? Lower the position of the thread take-up spring to as low a position as possible. Is the presser foot pressure too strong? Adjust the presser foot pressure. Is the sewing speed too fast? Use the sewing speed control keys to gradually reduce the sewing speed. Is the angle of the feed dog correct? Tilt the front of the feed dog down slightly. Instruction manual Instruction manual 26 26 Instruction manual Instruction manual 29 Is the presser foot pressure too strong? Adjust the presser foot pressure. Instruction manual 0750M 65 S-7200B