Brother International S-7200B Service Manual - Page 73

gauge window, add more oil., If the oil gauge is down to the lower reference line in the oil

|

View all Brother International S-7200B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 73 highlights

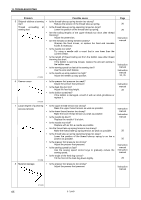

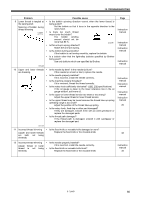

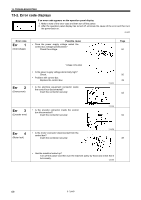

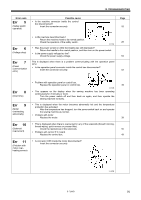

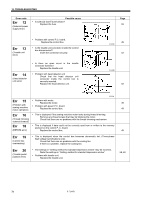

13. TROUBLESHOOTING Problem 9 Lower thread is tangled at the sewing start. Spinning of bobbin during thread trimming Lower thread 0751M 10 Upper and lower threads are breaking. 0471M 11 Incorrect thread trimming (Upper and lower threads are both not being trimmed) 12 Incorrect thread trimming (Upper thread or lower thread is not being trimmed) Possible cause Is the bobbin spinning direction correct when the lower thread is being pulled? Set the bobbin so that it turns in the opposite direction to the rotary hook. Is there too much thread wound onto the bobbin? The bobbin winding amount should not be more that 80 %. Is the anti-spin spring attached? Attach the anti-spin spring. 2124M Is the bobbin turning smoothly? If the bobbin is not turning smoothly, replace the bobbin. Is a bobbin other that the light-alloy bobbins specified by Brother being used? Use only bobbins which are specified by Brother. Page Instruction manual Instruction manual Instruction manual Instruction manual Is the needle tip bent? Is the needle tip blunt? If the needle tip is bent or blunt, replace the needle. Is the needle properly installed? If it is incorrect, install the needle correctly. Is the machine properly threaded? If it is incorrect, thread the thread correctly. Is the rotary hook sufficiently lubricated? (-[]0[], []3[] specifications) If the oil gauge is down to the lower reference line in the oil gauge window, add more oil. Is the upper or lower thread tension too weak or too strong? Adjust the upper thread or lower thread tension. Is the upper thread may be loose because the thread take-up spring operating range is too small? Adjust the position of the thread take-up spring. Is the rotary hook, feed dog or other part damaged? If they are damaged, smooth them with an oiled grindstone or replace the damaged parts. Is the thread path damaged? If the thread path is damaged, smooth it with sandpaper or replace the damaged part. Instruction manual Instruction manual Instruction manual Instruction manual 26 Is the fixed knife or movable knife damaged or worn? Replace the fixed knife or the movable knife. 38 Is the needle properly installed? If it is incorrect, install the needle correctly. Is the fixed knife or movable knife blunt? Replace the fixed knife or the movable knife. Instruction manual 38 S-7200B 66