Canon PC980 Service Manual - Page 343

Faulty Feeding, Double-Feeding, Wrinkles

|

UPC - 030275182323

View all Canon PC980 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 343 highlights

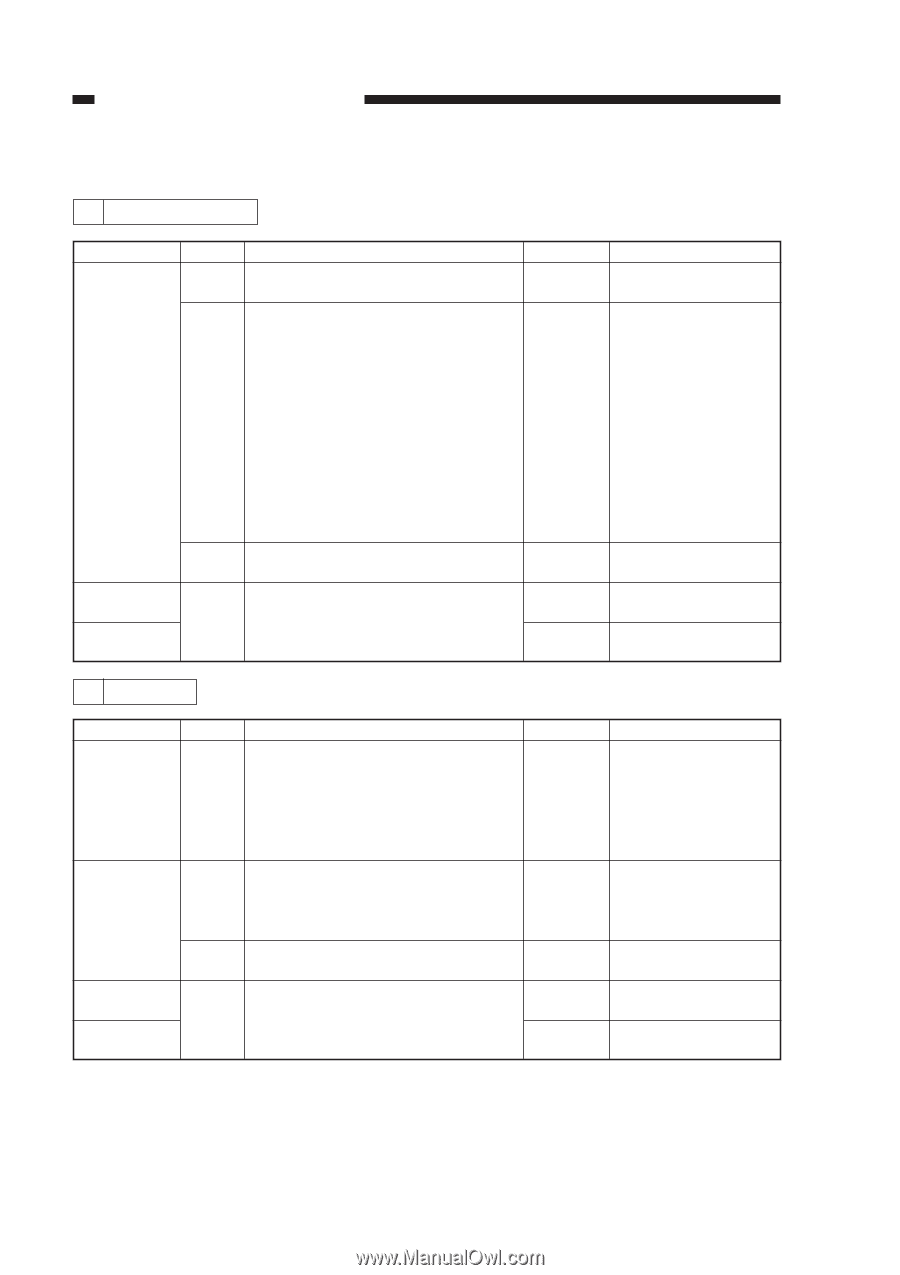

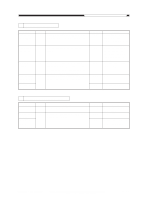

CHAPTER 11 TROUBLESHOOTING B. Faulty Feeding 1 Double-Feeding Cause Cassette Copy paper Claw (cassette) Step 1 2 3 4 Checks Is the copy paper placed under the claw properly? Push down the copy paper inside the cassette. Does it move up when let go with its end coming under the claw? Is the sheets of paper placed in the cassette uneven? Is the paper of a type recommended by Canon? YES/NO NO NO YES NO YES Action Place the copy paper properly. 1. Check the copy paper width. 2. Check the position of the side guide plate of the cassette. (universal cassette only) 3. Measure the force of the spring of the cassette; if faulty, replace the cassette spring. Even out the sheets in the cassette. Ask the user to use recommended paper. Check the claw for deformation. 2 Wrinkles Cause Pickup assembly, Vertical path roller, Registration roller Copy paper Fixing assembly Inlet guide Step 1 2 3 4 Checks Turn off the power while copy paper is moving through the feeding assembly. Is the copy paper wrinkled or found askew? Try fresh paper. Is the problem corrected? Try paper of a type recommended by Canon. Is the problem corrected? Is the inlet guide soiled with toner? YES/NO YES YES YES NO YES Action • Check the pickup assembly. • Check the vertical path roller. • Check the registra- tion roller. The paper is moist. Instruct the user on the correct method of storing paper. Ask the user to use recommended paper. Check the fixing assembly. Clean the inlet guide with solvent. 11-78 COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)