Canon PIXMA iP5200 Service Manual - Page 17

Repair, 3-1. Notes on Service Part Replacement - reset

|

View all Canon PIXMA iP5200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

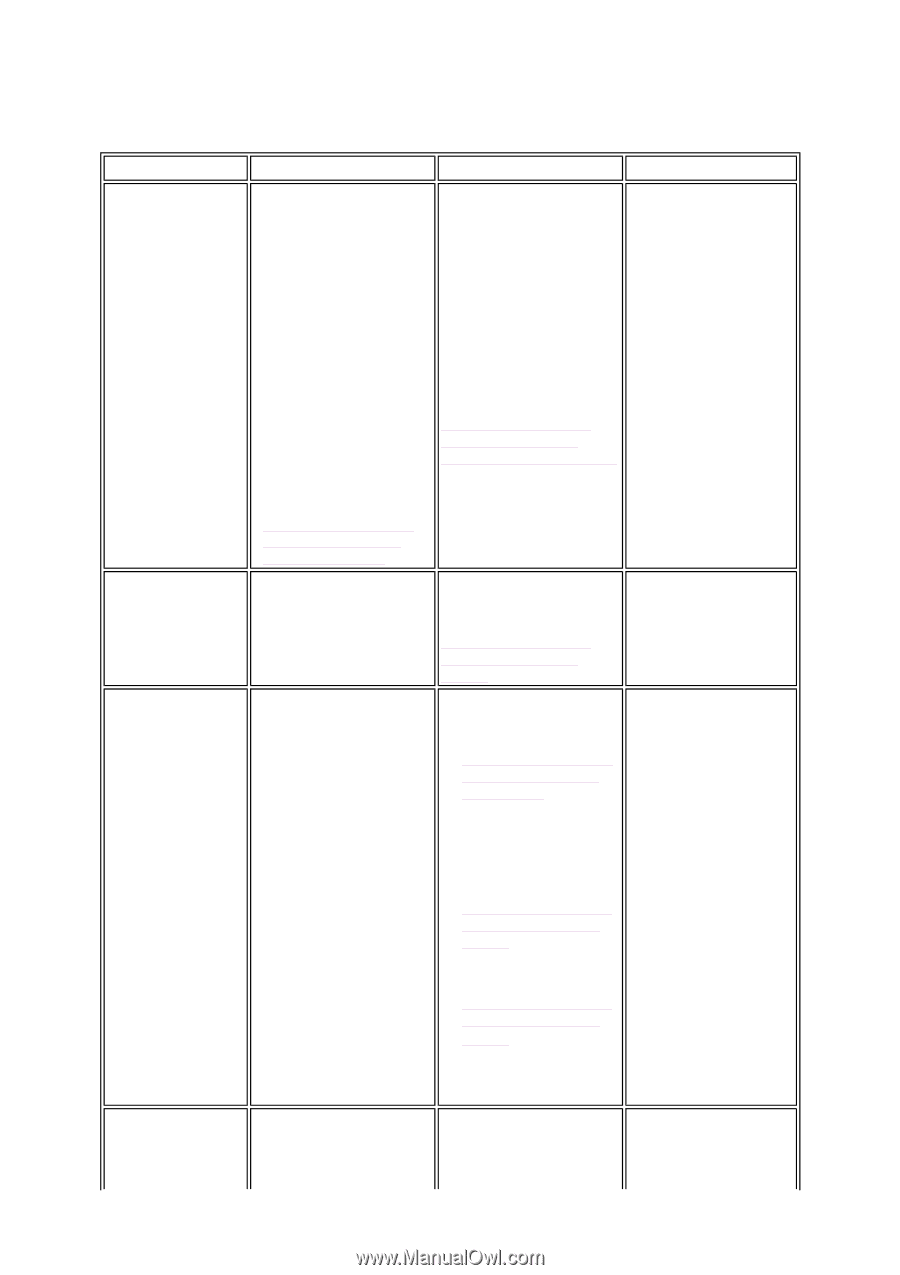

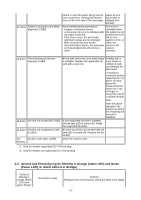

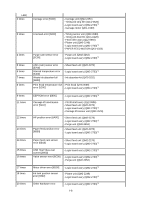

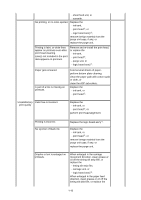

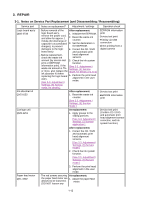

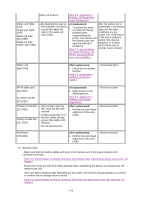

3. REPAIR 3-1. Notes on Service Part Replacement (and Disassembling / Reassembling) Service part Notes on replacement*1 Adjustment / settings Operation check Logic board ass'y QM2-2733 Ink absorber kit QY5-0152 Carriage unit QM2-2251 Paper feed motor QK1-1502 - Before removal of the After replacement: - EEPROM information logic board ass'y, remove the power cord, and allow for approx. 1 minute (for discharge of capacitor's accumulated charges), to prevent 1. Initialize the EEPROM. 2. Reset the waste ink counter. 3. Set the destination in the EEPROM. print - Service test print - Printing via USB connection - Direct printing from a damages to the logic 4. Correct the CD / DVD digital camera board ass'y. and automatic print - Before replacement, check the waste ink head alignment sensors. amount (by service test 5. Check the ink system print or EEPROM function. information print). If the [See 3-3. Adjustment / waste ink amount is 7% Settings, (5) Service or more, also replace the mode, for details of 1 to 5] ink absorber kit when replacing the logic board 6. Perform the print head ass'y. alignment in the user mode. [See 3-3. Adjustment / Settings, (5) Service mode, for details.] After replacement: 1. Reset the waste ink counter. [See 3.3. Adjustment / Settings, (5) Service mode.] - Service test print - EEPROM information print At replacement: 1. Apply grease to the sliding portions. [See 3-3. Adjustment / Settings, (2) Grease application.] - Service test print (Confirm CD / DVD and automatic print head alignment sensor correction, and ink system function.) After replacement: 1. Correct the CD / DVD and automatic print head alignment sensors. [See 3.3. Adjustment / Settings, (5) Service mode.] 2. Check the ink system function. [See 3.3. Adjustment / Settings, (5) Service mode.] 3. Perform the print head alignment in the user mode. - The red screws securing At replacement: the paper feed motor are 1. Adjust the paper feed allowed to be loosened. motor. (DO NOT loosen any 1-12