Canon PIXMA iP5200 Service Manual - Page 7

Customer Maintenance, To correct CD / DVD print

|

View all Canon PIXMA iP5200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

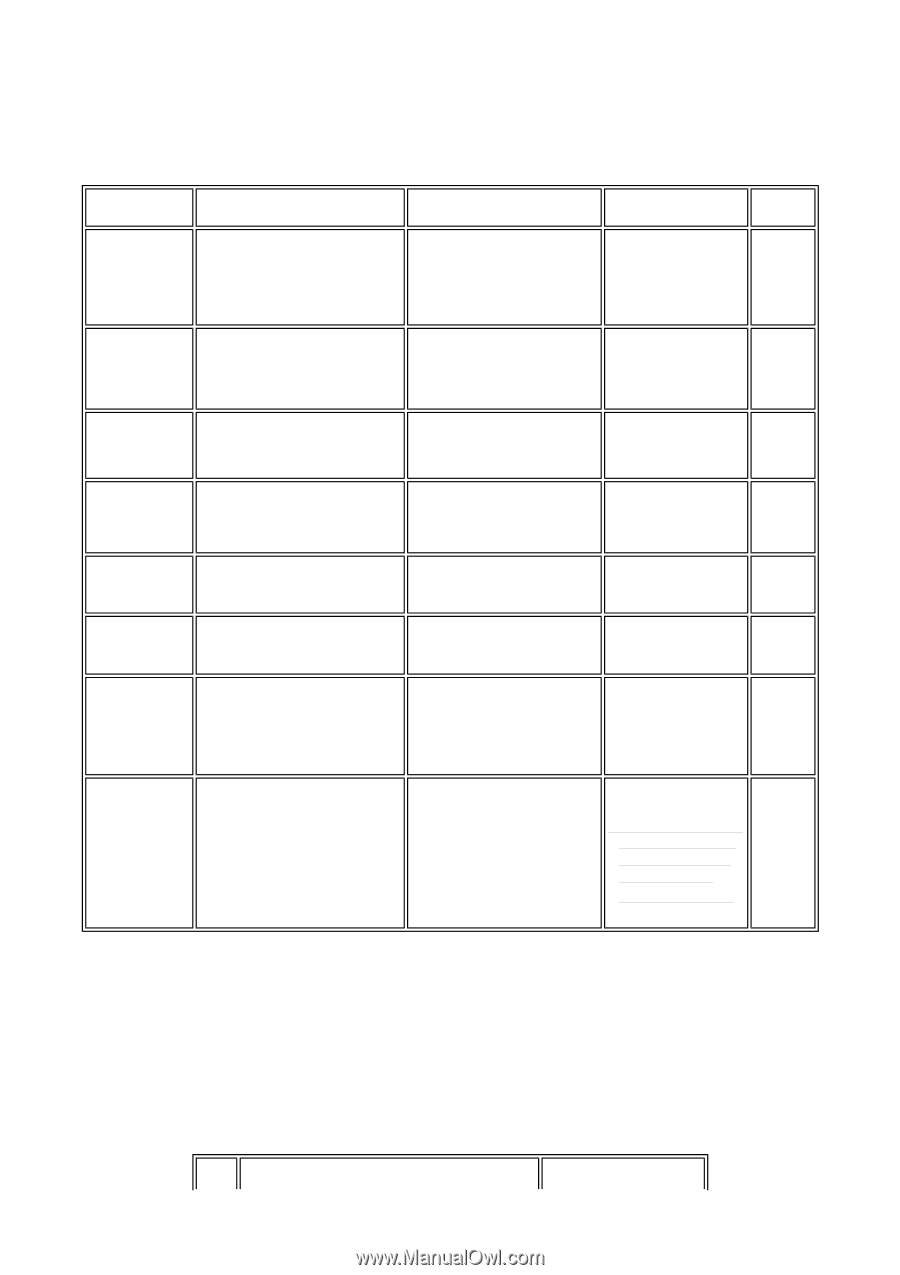

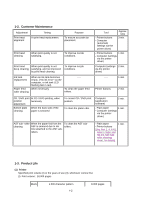

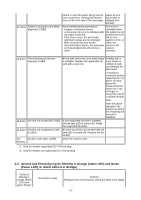

1-2. Customer Maintenance Adjustment Timing Print head alignment At print head replacement. Purpose To ensure accurate dot placement. Print head cleaning When print quality is not satisfying. To improve nozzle conditions. Print head When print quality is not deep cleaning satisfying, and not improved by print head cleaning. To improve nozzle conditions. Ink tank replacement Paper feed roller cleaning When an ink tank becomes empty. ("No ink error" via the computer, or ink tank LED flashing fast in red) When necessary ----- To clean the paper feed rollers. Tool - Printer buttons - Computer (automatic settings via the printer driver) Approx. time 3 min. - Printer buttons 1 min. - Computer (settings via the printer driver) Computer (settings 2 min. via the printer driver) ----- 1 min. Printer buttons 2 min. CD / DVD print At CD / DVD printing, when position necessary adjustment Bottom plate When the back side of the cleaning paper is smeared To correct CD / DVD print position. To clean the platen ribs. Computer (application software) 5 min. - Plain paper 1 min. - Computer (settings via the printer driver) ASF sub- roller When the paper fed from the To clean the ASF sub- cleaning ASF is smeared due to ink rollers. mist attached to the ASF sub- rollers. - Plain paper 1 min. - Printer buttons [See Part 2, 4. FAQ, How to make and set the ASF sub- roller cleaning sheet, for details] 1-3. Product Life (1) Printer Specified print volume (I) or the years of use (II), whichever comes first. (I) Print volume : 18,000 pages Black 1,500 character pattern 1-2 8,300 pages