Craftsman 25cc Operation Manual

Craftsman 25cc - Propane Curved Shaft Trimmer Powered by Lehr Manual

|

View all Craftsman 25cc manuals

Add to My Manuals

Save this manual to your list of manuals |

Craftsman 25cc manual content summary:

- Craftsman 25cc | Operation Manual - Page 1

POWERED LINE TRIMMER 16.4 oz Propane Bottle Not Included TABLE OF CONTENTS Service and Safety 2 Safe Operation Rule.s 3 Understanding Your Trimme...r 4 Assembly 5 Oil Information 6 Understanding Propan.e 7 Installing the Propane Canist.e..r 8 Installing Attachment - Craftsman 25cc | Operation Manual - Page 2

ECO-TRIMMER IMPORTANT SAFETY INSTRUCTIONS DU 4-CYCLE PROPANE TRIMMER READ ALL INSTRUCTION BEFORE OPERATING • Ne For service call 1-866-941-LEHR in the United States, to in obtain a list of authorized service dealers near you. • Inspect the unit before use. Replace damaged parts. u For - Craftsman 25cc | Operation Manual - Page 3

authorized service dealer. Use of any unau thorized parts or accessories could lead to serious injury to the user, or damage to the unit, and void your war ranty. • This unit has a clutch. The cutting attachment remains stationary when the engine is idling. If it does not, have the unit adjusted by - Craftsman 25cc | Operation Manual - Page 4

when needed. OIL : Refer to operator's manual for the proper type of oil. THROWN OBJECTS AND ROTATING CUTTER CAN CAUSE SEVERE INJURY WARNING: Do not operate without the cutting attachment shield in place. Keep away from the rotating cutting attachment. I ON/OFF STOP CONTROLS ON/START/RUN o ON - Craftsman 25cc | Operation Manual - Page 5

any rotating parts. CuttingAttachment Shield Spacer INSTALLING THE D-HANDLE AND LOWER HANDLE STRAIGHT SHAFT AND ACCESSORY READY TRIMMERS 1.Locate the Attaching Screws D-Handle Cap Washer Fig. 1 Attaching Screws FOR STRAIGHT SHAFT TRIMMERS Place the cutting attachment shield onto the shaft - Craftsman 25cc | Operation Manual - Page 6

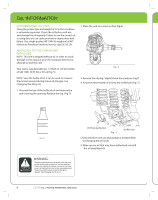

2. Place the unit on a level surface ( g.6). Fig. 6 3. Remove the oil plug / dipstick from the crankcase (Fig.7). 4. Pour the entire bottle of oil into the oil ll hole (Fig. 7). 4-Cycle Motor Oil Fig. 5 WARNING: Overfilling crankcase may cause hot oil to drip from air filter, and smoke to come out - Craftsman 25cc | Operation Manual - Page 7

seals. Discard cylinder if dirt or rust particles are in valve area. 2. Turn trimmer o . 3. Attach cylinder outdoors away from pilot lights, ames, sparks or other ignition sources. These sources can ignite leaking gas. 4. Hand tighten only. Never use tools to tighten. Overtightening can damage seals - Craftsman 25cc | Operation Manual - Page 8

will not latch securely to the unit and vibration may cause damage to the trimmer and potentially result in a dangerous leak. Fig. 9B Propane Connector 16.4 OUNCE/ 465 GRAM CANISTER REMOVING THE PROPANE CANISTER 1. Make sure the engine back so all of fuel line components are behind the guard and - Craftsman 25cc | Operation Manual - Page 9

with receiving hole will help installation (Fig. 10). Line up parts Coupler Receiving Hole Release Button NOTE: Always install the attachment so that the engine is upright (propane tank on bottom) when unit is oper ated. A secondary receiving hole is provided for use of a trimmer being used for - Craftsman 25cc | Operation Manual - Page 10

STARTING/STOPPING STARTING INSTRUCTIONS 1. Check the oil level in the crankcase. Refer to Checking the Oil Level ( p. 12). 2. Turn switch to ON position (Fig. 13). NOTE: If your unit is equipped with a spring loaded type ON/OFF switch, it will always remain in the ON position. 3. Place trimmer rmly - Craftsman 25cc | Operation Manual - Page 11

straight, the left hand hold ing the handle. • The unit is at waist level. • The cutting attachment is parallel to the ground and easily contacts the grass without the need to bend over. ADVANCING THE CUTTING LINE String advance is controlled by tapping the string head on grass while running engine - Craftsman 25cc | Operation Manual - Page 12

on the oil ll Full plug/dipstick when checking and changing the oil (Fig. 17). Add Fig. 17 WARNING: WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS. USE OF ANY OTHER PARTS MAY CREATE A HAZARD OR CAUSE PRODUCT DAMAGE Oil Fill Plug/ Dipstick WARNING: TO PREVENT EXTENSIVE ENGINE WEAR AND - Craftsman 25cc | Operation Manual - Page 13

rst 10 hours of operation. Change the oil while the engine is still warm but not hot. The oil will ow freely and carry away more impurities. 1. Unplug spark plug boot to prevent accidental starting. 2. Remove the oil ll plug/dipstick. 3. Pour the oil out of the oil ll hole and into a container by - Craftsman 25cc | Operation Manual - Page 14

the engine will not idle • the engine hesitates or stalls on acceleration •there is a loss of engine power Check the spark plug for proper gap and condition. If problem still occurs, have the carburetor adjusted by an authorized service dealer. REPLACING THE SPARK PLUGS Use a replacement part number - Craftsman 25cc | Operation Manual - Page 15

MAINTENANCE TRIMMER HEAD LINE INSTALLATION SMALL BUMP FEED HEAD (.080" Line) 1. Review gure 28 for names of parts referred to in these instructions. 2. Lock shaft by inserting allen key into hole in collar and turn until it engages groove inside. When shaft can no longer rotate, loosen head by - Craftsman 25cc | Operation Manual - Page 16

LARGE BUMP FEED HEAD (.095" Line) 1. Lock shaft by inserting allen key into groove. Loosen by turning head as shown for straight shaft. If your model is a curved shaft, loosen by turning opposite the direction shown in (Fig. 31). 2. Depress tab and twist trimmer head body CW to disassemble (Fig - Craftsman 25cc | Operation Manual - Page 17

by removing the screw. Replace when using line trimmer head (Fig. 41). Cotter Pin Left-Hand Thread Nut Screw Cutting Attachment Sheild Loosen Fig. 38 Bottom Shield Attachment 2. Insert an allen key into the hole in the shroud to lock the shaft. Remove the left-hand thread nut to dissasemble - Craftsman 25cc | Operation Manual - Page 18

(0.005in) feeler gage. WARNING: TO PREVENT SERIOUS INJURY, NEVER PERFORM MAINTENANCE OR REPAIRS WITH UNIT RUNNING. ALWAYS SERVICE AND REPAIR A COOL UNIT. DISCONNECT THE SPARK PLUG WIRE TO ENSURE THAT THE UNIT CANNOT START. Jam Nuts Feeler Gauge Exhaust Valve Intake Valve Fig.44 18 LEHR | ALL - Craftsman 25cc | Operation Manual - Page 19

propane canister. TROUBLE SHOOTING ENGINE WILL NOT START CAUSE ACTION EMPTY PROPANE CANISTER INSTALL FULL CANISTER BAD SPARK PLUG REPLACE THE SPARK PLUG ENGINE WILL NOT IDLE CAUSE ACTION AIR FILTER IS PLUGGED REPLACE THE AIR FILTER IMPROPER CARBURETOR ADJUSTMENT ADJUST ACCORDING - Craftsman 25cc | Operation Manual - Page 20

CLEARANCE SPARK PLUG GAP LUBRICATION CRANKCASE OIL CAPACITY FUEL CARBURETOR STARTER MUFFLER THROTTLE DRIVE SHAFT AND HOUSING DRIVE SHAFT HOUSING THROTTLE CONTROL APPROXIMATE UNIT WEIGHT CUTTING MECHANISM LINE SPOOL DIAMETER TRIMMING LINE DIAMETER CUTTING PATH DIAMETER AIR COOLED 4-CYCLE 25.4 CC - Craftsman 25cc | Operation Manual - Page 21

to the operating instructions speci ed in this operator's manual. Additionally, this warranty does not cover tune-ups, spark plugs, carburetor adjustments, lters, cutting line, bump knobs, outer spools, inner reels, starter pulley, or rotating head parts that will wear and require replacement - Craftsman 25cc | Operation Manual - Page 22

NOTES 22 LEHR | ALL RIGHT RESERVED 2008-2009

Service and Safety

.............................................................

2

Safe Operation Rules

..........................................................

3

Understanding Your Trimmer

...............................................

4

Assembly

...........................................................................

5

Oil Information

....................................................................

6

Understanding Propane

......................................................

7

Installing the Propane Canister

............................................

8

Installing Attachments

.........................................................

9

Starting / Stopping

...........................................................

10

Operation

.........................................................................

11

Maintenance

....................................................................

12

Cleaning and Storage

.......................................................

19

Troubleshooting

................................................................

19

Speci¯cations

..................................................................

20

Warranty

..........................................................................

21

PROPANE POWERED LINE TRIMMER

16.4 oz Propane Bottle

Not Included

ST 025SS

ST 025

DC

ST 025CS

ST 025

DS

DO NOT RETURN THE UNIT

TO THE RETAILER

Call 1-866-941-LEHR (5347)

OPERATOR’S MA

NUAL

ECO-TRIMMER

MODELS:

TABLE OF CONTENTS

WARNING:

THE ENGINE EXHAUST FROM THIS

PRODUCT CONTAINS CHEMICALS

KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER, BIRTH DEFECTS

OR OTHER REPRODUCTIVE HARM.

LEHR

|

ALL RIGHTS RESERVED 2008-2009