Cub Cadet Z Force S 54 Z-Force S 48 Operator's Manual - Page 22

Adjustments

|

View all Cub Cadet Z Force S 54 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

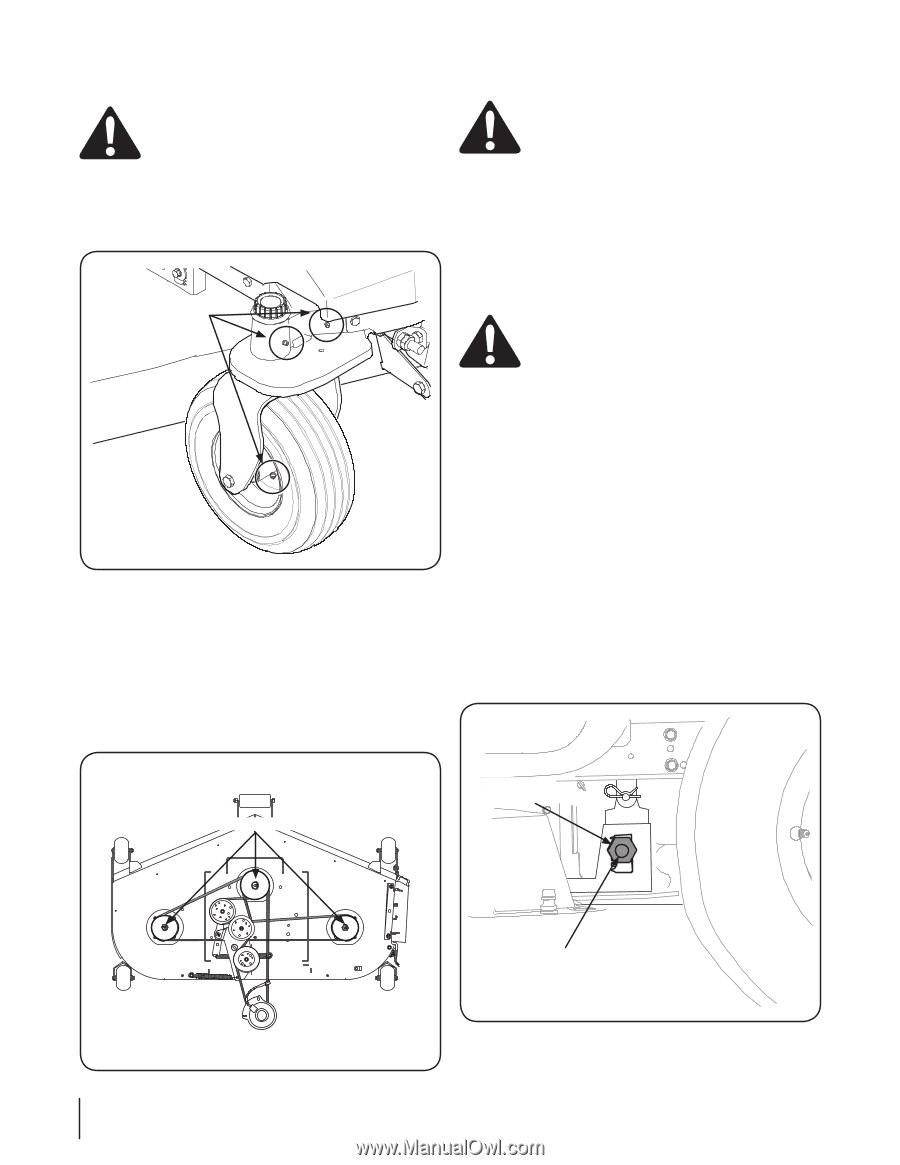

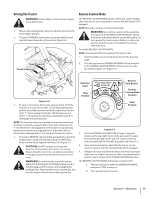

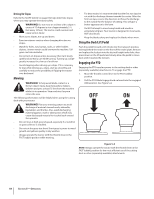

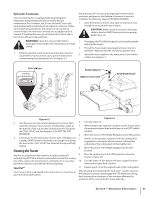

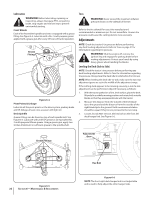

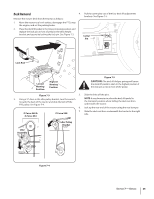

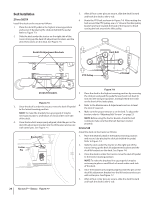

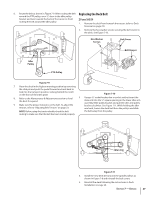

Lubrication WARNING! Before lubricating, repairing, or inspecting, always disengage PTO, set parking brake, stop engine and remove key to prevent unintended starting. Front Wheels Each of the front wheel spindles and rims is equipped with a grease fitting. See Figure 6-4. Lubricate with a No. 2 multi-purpose grease applied with a grease gun after every 25 hours of tractor operation. Grease Fittings Figure 6-4 Pivot Points & Linkage Lubricate all the pivot points on the drive system, parking brake and lift linkage at least once a season with light oil. Deck Spindle Grease fittings can be found on top of each spindle bolt. See Figure 6-5. Lubricate with 251H EP grease or an equivalent No. 2 multi-purpose lithium grease. Using a grease gun, apply two strokes (minimum) or sufficient grease to the spindle shaft. Tires WARNING! Never exceed the maximum inflation pressure shown on the sidewall of the tire. Refer to the tire sidewall for exact tire manufacturer's recommended or maximum psi. Do not overinflate. Uneven tire pressure could cause the cutting deck to mow unevenly. Adjustments NOTE: Check the tractor's tire pressure before performing any deck leveling adjustments. Refer to Tires on page 21 for information regarding tire pressure. WARNING! Shut the engine off, remove the ignition key and engage the parking brake before making adjustments. Protect your hands by using heavy gloves when handling the blades. Leveling the Deck (Side to Side) NOTE: Check the tractor's tire pressure before performing any deck leveling adjustments. Refer to Tires for information regarding tire pressure. Always level the deck side to side before front to rear. NOTE: When leveling the deck side-to-side, make sure the two rear adjustment gears are set in the middle of the adjustment range. If the cutting deck appears to be mowing unevenly, a side to side adjustment can be performed. Adjust if necessary as follows: 1. With the tractor parked on a firm, level surface, place the deck lift pedal in a middle mowing position and rotate both outside blades so that they are perpendicular with the tractor. 2. Measure the distance from the outside of the left blade tip to the ground and the distance from the outside of the right blade tip to the ground. Both measurements taken should be equal. If they're not, proceed to the next step. 3. Loosen, but do NOT remove, the hex bolt on the front left deck hanger link. See Figure 6-6. Grease Fittings Adjustment Gear Figure 6-5 22 Section 6- Maintenance & Adjustments Hex Bolt Figure 6-6 NOTE: The front right deck hanger link is not adjustable and is used to help adjust the other hanger links.