Dell B1160W User Manual - Page 29

Card stock/ Custom-sized paper, Preprinted paper - ink

|

View all Dell B1160W manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

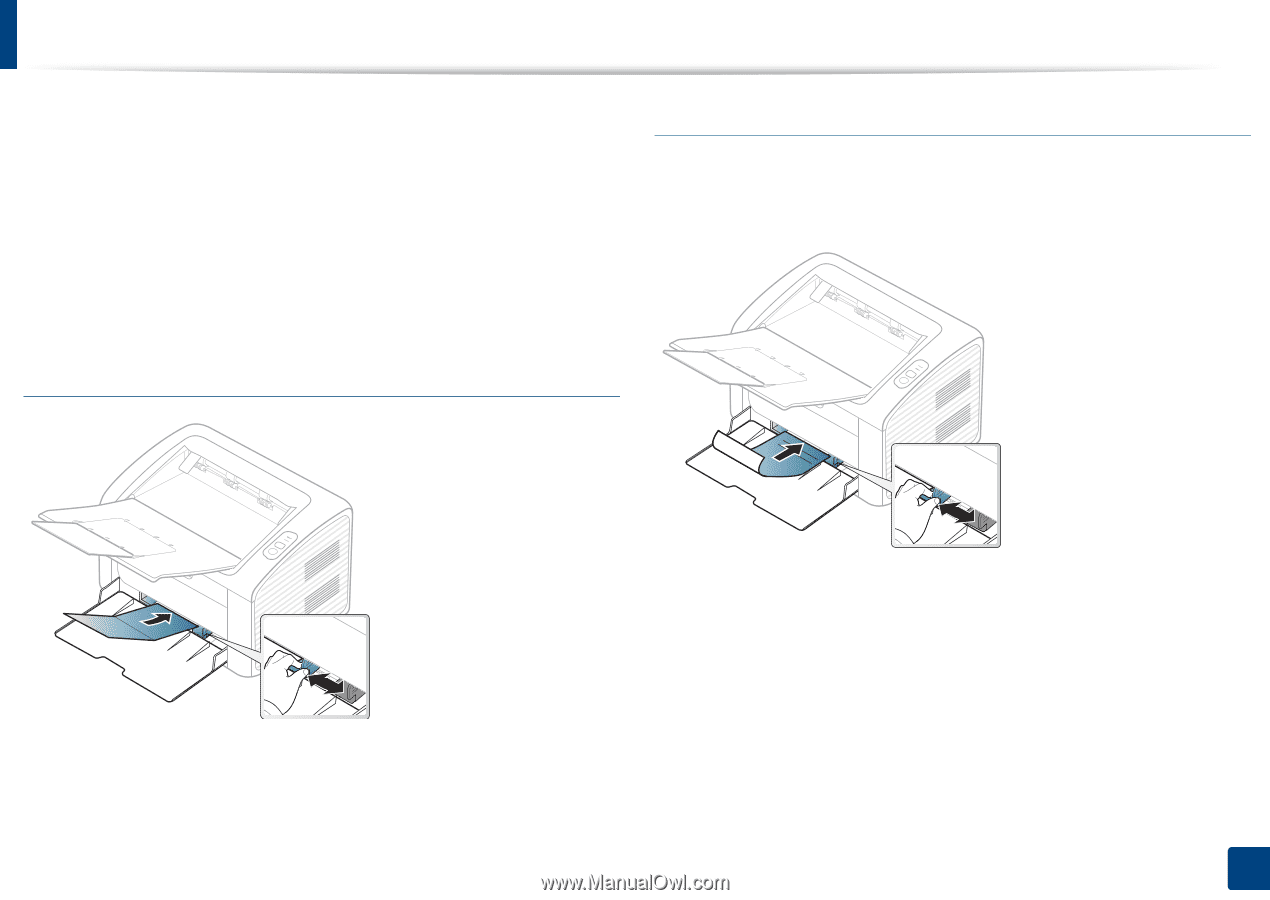

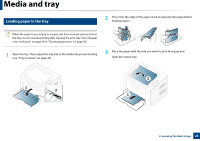

Media and tray • Make sure that there is no exposed adhesive material between labels. Exposed areas can cause labels to peel off during printing, which can cause paper jams. Exposed adhesive can also cause damage to machine components. • Do not run a sheet of labels through the machine more than once. The adhesive backing is designed for only a single pass through the machine. • Do not use labels that are separating from the backing sheet or are wrinkled, bubbled, or otherwise damaged. Preprinted paper When loading preprinted paper, the printed side should be facing up with an uncurled edge at the front. If you experience problems with paper feeding, turn the paper around. Note that print quality is not guaranteed. Card stock/ Custom-sized paper • In the software application, set margins at least 6.4 mm (0.25 inches) away from the edges of the material. • Must be printed with heat-resistant ink that will not melt, vaporize, or release hazardous emissions when subjected to the machine's fusing temperature for 0.1 second (about 170°C (338°F)). • Preprinted paper ink must be non-flammable and should not adversely affect machine rollers. • Before you load preprinted paper, verify that the ink on the paper is dry. During the fusing process, wet ink can come off preprinted paper, reducing print quality. 2. Learning the Basic Usage 29