Electrolux EI24ID50QS Wiring Diagram (English)

Electrolux EI24ID50QS Manual

|

View all Electrolux EI24ID50QS manuals

Add to My Manuals

Save this manual to your list of manuals |

Electrolux EI24ID50QS manual content summary:

- Electrolux EI24ID50QS | Wiring Diagram (English) - Page 1

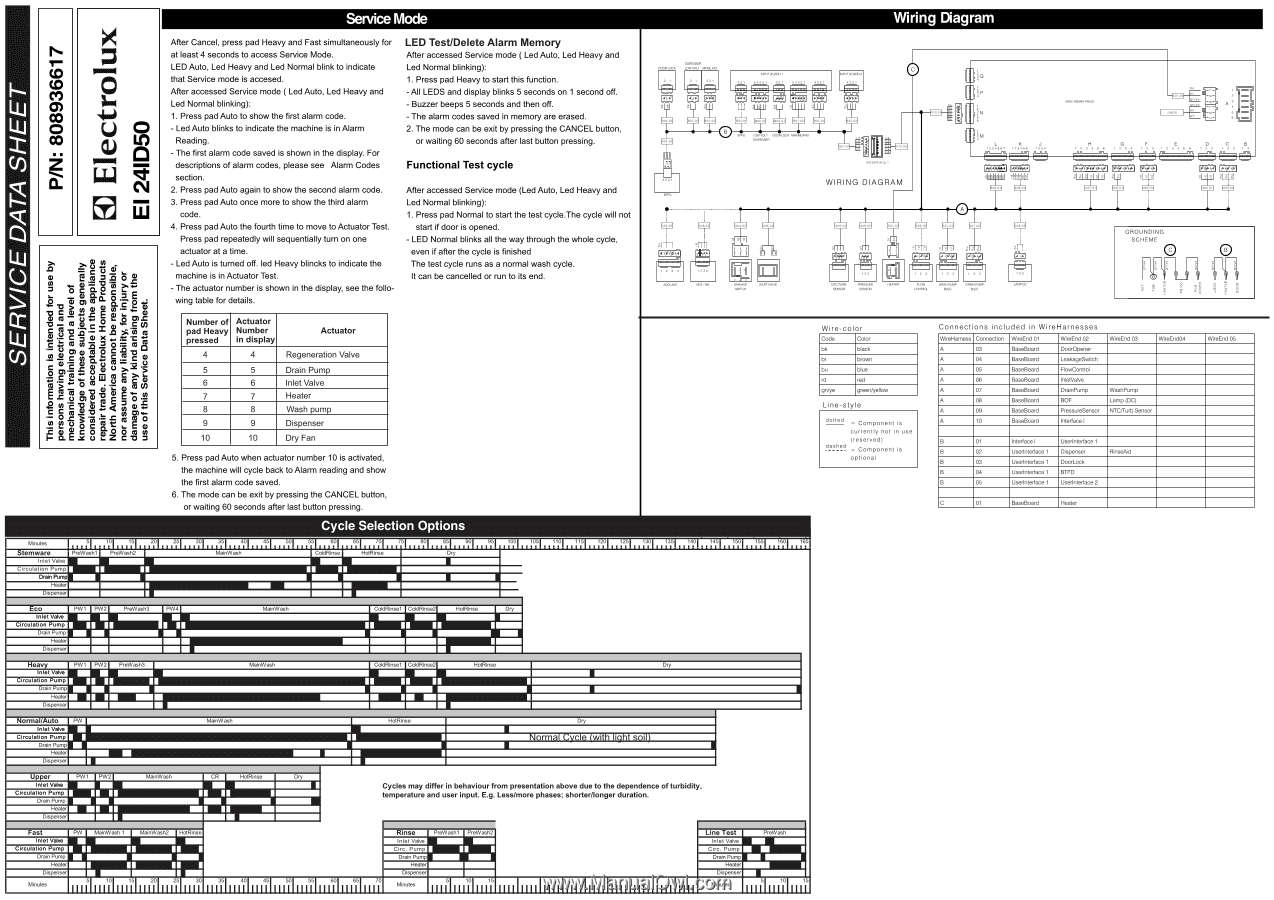

button pressing. Functional Test cycle After accessed Service mode (Led Auto, Led Heavy and BOARD, 54921 921 54821 4221 PUT BOARD BO 0 IIIII TT B LOW VOLT COORLOCK MAINBOARD °SPENSER INTERFACE I WIRING DIAGRAM Di ° 10 0 0 • 11 Wire-color Code Color bk black br brown bu blue rd - Electrolux EI24ID50QS | Wiring Diagram (English) - Page 2

Spray Arm Support Lower Spray Arm Trouble Shooting Tips The door gasket is pressed into the tub channel for an interference fit. To install components. (1 to 24 hours). Cancelling a Symptom be unresponsive. 8. Touch pad circuit defective. problem iF0 Water level problem Dishwasher

SERVICE

DATA

SHEET

P/N:

808936617

O

u

O

cu

w

LT

,

).

8

$

as

.o

=

.0

o

0

"a

I

73.?0t.

4"

C)a.

E

v

0)

C3

•ELEeZ

13-

el

s,

C

.2

cats

E.-

.5

0

CIS

2

.-

c

x

•E

4-

ct

ogir

2

215=a)

Me

03

e

ciav

mace

0

.

uca-

m

o

co.c-c

8

u

.2

c

i-„

Te

c>.

t

3

ma 413 •

63

5

co

€2

0

141

Prig-

0

2

121

e

E

Or

aar./0,

4

c

c

r

t

1

13

°E0occcit

1

al

:Ea)0covooma)

i-o.E_vo

zc•oc

After

Cancel,

press

pad

Heavy

and

Fast

simultaneously

for

at

least

4

seconds

to

access

Service

Mode.

LED

Auto,

Led

Heavy

and

Led

Normal

blink

to

indicate

that

Service

mode

is

accesed.

After

accessed

Service

mode

(

Led

Auto,

Led

Heavy

and

Led

Normal

blinking):

1.

Press

pad

Auto

to

show

the

first

alarm

code.

-

Led

Auto

blinks

to

indicate

the

machine

is

in

Alarm

Reading.

-

The

first

alarm

code

saved

is

shown

in

the

display.

For

descriptions

of

alarm

codes,

please

see

Alarm

Codes

section.

2.

Press

pad

Auto

again

to

show

the

second

alarm

code.

3.

Press

pad

Auto

once

more

to

show

the

third

alarm

code.

4.

Press

pad

Auto

the

fourth

time

to

move

to

Actuator

Test.

Press

pad

repeatedly

will

sequentially

turn

on

one

actuator

at

a

time.

-

Led

Auto

is

turned

off.

led

Heavy

blincks

to

indicate

the

machine

is

in

Actuator

Test.

-

The

actuator

number

is

shown

in

the

display,

see

the

follo-

wing

table

for

details.

Number

of

pad

Heavy

pressed

Actuator

Number

in

display

Actuator

4

4

Regeneration

Valve

5

5

Drain

Pump

6

6

Inlet

Valve

7

7

Heater

8

8

Wash

pump

9

9

Dispenser

10

10

Dry

Fan

5.

Press

pad

Auto

when

actuator

number

10

is

activated,

the

machine

will

cycle

back

to

Alarm

reading

and

show

the

first

alarm

code

saved.

6.

The

mode

can

be

exit

by

pressing

the

CANCEL

button,

or

waiting

60

seconds

after

last

button

pressing.

LED

Test/Delete

Alarm

Memory

After

accessed

Service

mode

(

Led

Auto,

Led

Heavy

and

Led

Normal

blinking):

1.

Press

pad

Heavy

to

start

this

function.

-All

LEDS

and

display

blinks

5

seconds

on

1

second

off.

-

Buzzer

beeps

5

seconds

and

then

off.

-

The

alarm

codes

saved

in

memory

are

erased.

2.

The

mode

can

be

exit

by

pressing

the

CANCEL

button,

or

waiting

60

seconds

after

last

button

pressing.

Functional

Test

cycle

After

accessed

Service

mode

(Led

Auto,

Led

Heavy

and

Led

Normal

blinking):

1.

Press

pad

Normal

to

start

the

test

cycle.The

cycle

will

not

start

if

door

is

opened.

-

LED

Normal

blinks

all

the

way

through

the

whole

cycle,

even

if

after

the

cycle

is

finished

The

test

cycle

runs

as

a

normal

wash

cycle.

It

can

be

cancelled

or

run

to

its

end.

IIIII

•-

DISPE

._

NSE

T

R

ND

BO

0

B

INPUT

BOARD,

921

54921

921

54821

4221

TT

LOW

VOLT

COORLOCK

MAINBOARD

°SPENSER

PUT

BOARD

INTERFACE

I

WIRING

DIAGRAM

10

0

hoe.21

SOF/.

I

FAKAr,

INLET

VALVE

swoc55

Ftfi

NTOTURB

SENSOR

PRESSURE

SENSOR

Di

°

L

K

J

129450)

129450

1294

BASE

BOARD

PB100

0

C

a

2

9

H

4

5

8

1

2

9

4

1

2

9.

1

2

9

4

5

8

1

2

9

1

2

9

1

2

21

2

nn

FLOW

WASH

PUMP

PPM

PUMP

CONTROL

BLDC

BLDG

•

GROUNDING

SCHEME

O

0

1

1

Minutes

5

10

15

20

25

601

651

701

751

801

851

901

951

1001

1051

1101

1151

1201

1251

1301

1351

1401

1451

1501

1551

1601

165

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiIiiiiIiiiiliiiiliiiiliiiiliiiiliiiiliiiiliiiiliiiiliiiiliiiiliiiiliiiiliiii

mware

PreWash1

Inlet

Valve

Circulation

Pump

Drain

Pum

PreWash2

MainWash

ColdRinse

HotRinse

Dry

Heater

Dispenser

Eco

PW1

PW2

PreWash3

PW4

MainWash

ColdRinse1

ColdRinse2

HotRinse

ry

Inlet

Valve

Circulation

Pump

Drain

Pump

Heater

Dispenser

Heavy

PW1

PW2

PreWash3

MainWash

ColdRinse1

ColdRinse2

HotRinse

Dry

Inlet

Valve

ircu

a

ion

-

ump

.ram

-

ump

.

Heater

Dispenser

Normal/Auto

PW

MainWash

HotRinse

ry

Inlet

Valve

Circulation

Pump

Drain

Pump

Heater

Dispenser

himmaLCa.cleauttiligaLaa

Upper

PW1

PW2

MainWash

CR

HotRinse

ry

Inlet

Valve

Circulation

Pump

Drain

Pump

Heater

Dispenser

Fast

PW

MainWash

1

MainWash2

HotRinse

Cycles

may

differ

in

behaviour

from

presentation

above

due

to

the

dependence

of

turbidity,

temperature

and

user

input.

E.g.

Less/more

phases;

shorter/longer

duration.

ro

se

Wire

-color

Code

Color

bk

black

br

brown

bu

blue

rd

red

gn/ye

green/yellow

Line

-sty

e

dotted

=

Component

is

currently

not

in

use

(reserved)

dashed

Component

is

optional

Connections

included

in

WireHarnesses

WireHamess

Connection

WireEnd

01

WireEnd

02

WireEnd

03

WireEnd04

WireEnd

05

A

03

BaseBoard

DoorOpener

A

04

BaseBoard

LeakageSwitch

A

05

BaseBoard

FlowControl

A

06

BaseBoard

InletValve

A

07

BaseBoard

DrainPump

WashPump

A

08

BaseBoard

BOF

Lamp

(DC)

A

09

BaseBoard

PressureSensor

NTC/Turb

Sensor

A

10

BaseBoard

Interface

I

B

01

Interface

I

Userinterface

1

B

02

Userinterface

1

Dispenser

RinseAid

B

03

Userinterface

1

DoorLock

B

04

Userinterface

1

BTFD

B

05

Userinterface

1

Userinterface

2

C

01

BaseBoard

Heater

Inlet

Valve

Circulation

Pump

Drain

Pump

Heater

Dispenser

Inlet

Valve

Inlet

Valve

Circ.

Pump

II

Drain

Pum.

Drain

Pum.

Heater

Heater

Dispenser

Dispenser

Minutes

5

10

25

30

111111111

15

2

1111111111

1111

1111

lllllllllllllllllllllllllllllllllll

51

70

51

101

15

1

1

15

IIII

Minutes

Minutes

IIII