Electrolux EIED55HIW Wiring Diagram (All Languages)

Electrolux EIED55HIW - 8.0 cu. Ft. Electric Dryer Manual

|

UPC - 012505378614

View all Electrolux EIED55HIW manuals

Add to My Manuals

Save this manual to your list of manuals |

Electrolux EIED55HIW manual content summary:

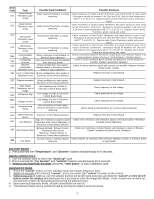

- Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 1

and connections for open circuits. Replace heater and/or Heating element or wiring defective wiring and retest. For Electric Model, check Inlet Thermal Limiter for continuity. If Thermal Limiter High Limit High vent restriction, High Limit is open, check for evidence of high temperature event - Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 2

defective wiring problems, replace Electronic low EA4 Improper home wiring Wrong configuration data loaded, Electronic Control Board defective Line frequency out of limits dryer and press "start pause" to start installation cycle. DIAGNOSTIC MODE 1. Press the "cancel" button to enter standby mode - Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 3

clear the error code (s): Press and hold the far left key under the display and "cancel" buttons simultaneously for 3 seconds. 6. To exit Diagnostic Mode: a) Unplug the power cord, wait 5-8 seconds, then reconnect the power cord OR b) Turn the program knob to the Start Position (lights/Buttons Test - Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 4

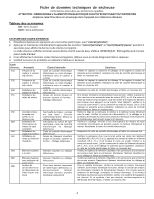

5 derniers codes d'erreur enregistrés, référez-vous au mode Diagnostic listé ci-dessous. 4. Vérifiez la source limite-haute défectueux ou du thermostat de déclenchement limiteur limite démarre pas lorsque vous appuyez sur la touche "start (départ)", vérifiez si le circuit est ouvert entre L1 et - Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 5

carte de contrôle compatible avec la carte d'interface électronique correctes sont installées. Remplacez le matériel approprié. E93 Erreur du total de Chargement ôle électronique défectueuse EA1 Fréquence Fréquence de ligne hors limites ou Vérifiez la fréquence de la tension de ligne et faites - Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 6

pendant 6 secondes. 3. Retirez le linge de la sécheuse et appuyez sur "start (départ) / pause" pour lancer le cycle d'installation MODE DIAGNOSTIC 1. Appuyez sur le bouton CANCEL (Annuler) pour passer en mode de veille et activer l'entrée de diagnostic. 2. Dans les 10 secondes suivant l'utilisation - Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 7

Hoja técnica de secadora Esta información está destinada exclusivamente a los técnicos calificados. PRECAUCIÓN: DESCONECTE LA CORRIENTE ELÉCTRICA ANTES DE DAR MANTENIMIENTO O SERVICIO Por favor devuelva esta hoja a su sobre en el producto para referencia futura Tabla de acrónimos SH - Sentido - Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 8

Código de error E66 Falla Circuito de limitador térmico abierto Posible Condiciones de falla Limitador térmico de salida desactivado limitador térmico de entrada desactivado (sólo modelo de gas) o cableado defectuoso Soluciones posibles Compruebe la continuidad del limitador térmico de salida. - Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 9

RECUPERAR LA CONFIGURACIÓN DE FÁBRICA 1. Mantenga presionados los botones "Temperature" y"Dryness" simultáneamente por 6 segundos. CICLO DE INSTALACIÓN 1. Use la perilla para seleccionar el ciclo de "touch up" 2. Mantenga presionados los botones "my favorite" y "sanitize" simultáneamente por 6 - Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 10

- Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 11

- Electrolux EIED55HIW | Wiring Diagram (All Languages) - Page 12

137032700 10

137032700B (0209)

Dryer Tech Data Sheet

This information is intended for Qualified Technicians Only.

CAUTION: DISCONNECT ELECTRICAL CURRENT BEFORE SERVICING

Please Return This Sheet to its Envelope in the Product for Future Reference

Acronym T

able

CW

– Clockwise

CCW

– Counter Clockwise

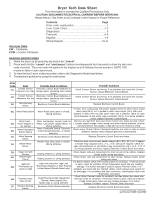

READING ERROR CODES

1.

Wake the dryer up by pressing any button but “

cancel

”.

2.

Press and hold the

“cancel

”

and

“

start pause

” buttons simultaneously for 6 seconds to show the last error

code recorded.

The error code will appear in the display as an E followed by two numbers. NOTE: E00

means no failure code experienced.

3.

To view the last 5 error codes recorded, refer to the Diagnostic Mode listed below.

4.

Troubleshoot problem by using the chart below.

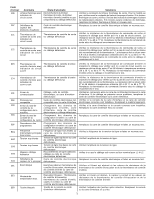

Error

Code

E31

E32

E42

E51

E52

E53

E54

E61

E63

E64

E65

E66

E67

Fault

Contact Sensor

frequency too high

Contact Sensor

frequency too low

Door Sensing

failure

Motor Relay failure

Motor Fault –

motor stopped or

not starting

Motor Centripetal

Switch Failure

Motor Sensing

failure

Heater Relay

failure

Heater to Earth

Ground

Heater Open

Circuit

High Limit

Thermostat trip

count too high

Thermal Limiter

Open Circuit

Heaters Sensing

Failure

Possible Fault Conditions

Electronic Control Board defective or

foreign object interfering with contact

sensor

Electronic Control Board defective or

foreign object interfering with contact

sensor

Electronic Control Board defective

Motor Relay stuck open or closed;

Wiring defective

Motor overheating; Laundry load too

heavy; Low power supply; Motor, or

Wiring defective

Motor Centripetal Switch, Electronic

Control Board Defective, or wiring

defective.

Electronic Control Board defective

Heater relay stuck open or closed;

Wiring defective

Heating element or wiring defective

Heating element or wiring defective

High vent restriction, High Limit

Thermostat defective or Inlet Thermal

Limiter tripped (Electric Model only)

Outlet Thermal Limiter tripped Inlet

Thermal Limiter tripped (Gas

Model only) or wiring defective

Electronic Control Board defective

Possible Solutions

Check Contact Sensor and wiring. If no problems are found with Contact

Sensor, replace Electronic Control Board.

Check Contact Sensor and wiring. If no problems are found with Contact

Sensor, replace Electronic Control Board.

Replace Electronic Control Board.

If motor runs continuously with power applied check for short circuit across

motor relay (RL2), or L1 applied to motor relay output (J3-1) with cycle

stopped. If motor does not start when “start” key is pressed, check for open

circuit between L1 and motor relay connection (J3-2). If no wiring problems

found, replace Electronic Control Board.

Remove any load from dryer and check if drum turns freely by hand. Check

L1 power supply voltage, motor wiring, and motor thermal protector (if motor

thermal protector has tripped, it may take up to 30 minutes to reset).

Check wiring. Check if Motor Centripetal Switches are stuck in open or closed

positions. Replace motor. Replace Electronic Control Board.

Replace Electronic Control Board and retest.

Check for short circuit across heater relay(s) (RL5, RL6, RL7) or L1 applied

to heater relay output(s) (J5-2, J7-1, J7-3)

with cycle stopped. Check for

open circuit between L1 and heater relay connection(s) (J5-1, J5-3, J7-2). If

no wiring problems are found, replace Electronic Control Board and retest.

Check heater coils and connections for short circuits to the cabinet. Replace

heater and/or wiring and retest.

Check heater coils and connections for open circuits. Replace heater and/or

wiring and retest.

For Electric Model, check Inlet Thermal Limiter for continuity.

If Thermal Limiter

is open, check for evidence of high temperature event and any resulting

damage. If no further damage is evident, replace Thermal Limiter. If no

problems are found with the Thermal Limiter, check exhaust vent system for

air blockages. If no problems with vent restrictions, check/replace High Limit

Thermostat, and retest.

Check Outlet Thermal Limiter for continuity. For Gas Model, also check Inlet

Thermal Limiter for continuity.

If Thermal Limiter is open, check for evidence

of high temperature event and any resulting damage. If no further

damage is evident, replace Thermal Limiter and retest.

Replace Electronic Control Board and retest.

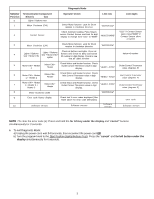

Contents

Page

Error code explanation

.............................................

1

Error Code Chart

....................................................

1-2

Diagnostics

.................................................................

3

Français…………………………………………

......

4-6

Español…………………………………………

..............

7-9

Wiring Diagram……………………………………

.......

10-11