Frigidaire FGHB2844LF Wiring Diagram (All Languages)

Frigidaire FGHB2844LF Manual

|

UPC - 012505698040

View all Frigidaire FGHB2844LF manuals

Add to My Manuals

Save this manual to your list of manuals |

Frigidaire FGHB2844LF manual content summary:

- Frigidaire FGHB2844LF | Wiring Diagram (All Languages) - Page 1

Service Manual for complete description. 22 Damper 23 Fresh food door 24 Freezer door 26 Defrost limit switch 28 Dispenser paddle 36 Ice door 29 FF Thermistor 30 FZ Thermistor 33 Ambient Thermistor 0- Software version Evaporator fan De-activate: Hold FF (+) for 5 sec. FREEZER iCE MAKER - Frigidaire FGHB2844LF | Wiring Diagram (All Languages) - Page 2

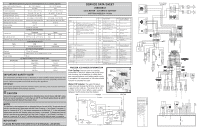

242058901 Wiring Diagram Frig FDBF 2500++ V4 with Dispenser

SERVICE DATA SHEET

240389643

ICE & WATER - AUTOMATIC DEFROST

BOTTOM FREEZER - R134a

IMPORTANT SAFETY NOTE

The information provided herein is designed to assist qualified repair personnel only.

Untrained persons should not attempt to make repairs due to the possibility of electrical

shock. Disconnect power cord before servicing this appliance.

IMPORTANT

If any green grounding wires are removed during servicing, they must be returned to

their original position and properly secured.

CAUTION

All electrical parts and wiring must be shielded from torch flame. DO NOT allow

torch to touch insulation; it will char at 200°F and flash ignite (burn) at 500°F.

Excessive heat will distort the plastic liner.

NOTE

This product comes equipped with an Adaptive Defrost Control (ADC). To activate manual

defrost, simultaneously press and hold the Fresh Food up (+) and Fresh Food down (-)

keys for 5 seconds. A “d” in the freezer temperature window and “F” in the refrigerator

temperature window will display when the heater is activated. To deactivate manual

defrost, simultaneously press and hold the Fresh Food up (+) and Fresh Food down (-)

keys for 5 seconds. A “d” and “F” will be displayed until the defrost cycle is complete.

PERFORMANCE DATA NO LOAD & NO DOOR OPENINGS AT 37°/0° CONTROL SETTING

Type A with Run/Start Capacitor

65°F (18°C) Ambient

90°F (32°C) Ambient

Operating Time

74 to 84%

100%

Freezer Temperature

-5° to 2° F (-20° to -17° C)

-1° to 3° F

(-18° to -16° C)

Refrigerator Temperature

34° to 39° F (1° to 4° C)

34° to 39° F

(1° to 4° C)

Low Side Pressure

(cut-in)

5 to 12 psig

(34 to 83 kPa)

N/A

Low Side Pressure

(cut-out)

-2 to 2 psig

( -14 to 14 kPa)

-2 to 2 psig

(-14 to 14 kPa)

High Side Pressure (last 1/3 cycle)

85 to 95 psig

(586 to 655 kPa)

120 to 135 psig

(827 to 931 kPa)

Wattage (last 1/3 cycle)

45 to 55

60 to 70

Amps (running)

.6 to 1.1

.7 to .9

Base Voltage

115 vac (127 vac max)

DEFROST SPECIFICATIONS

Cabinet Size

Thermostat

Heater

Cut-in

Cut-out

Watts

Ohms

26’ & 28’ SD, 23’ CD

25° F (-4° C)

47° F (8° C)

500

31

Electronic Timer - (ADC) Defrost 24 minutes every 6-96 hours of compressor run time.

CONDENSER FAN MOTOR

Watts

RPM

Amps

3.1

1100 CW Opposite Shaft

0.03 Running

ICE MAKER SPECIFICATIONS

Electrical

115 vac (127 vac max)

Thermostat

Opens at 48° F ( 9° C), Closes at 15° F ( -9° C)

Heater Voltage

85 vac

ICE MAKER CONNECTOR PLUG CONNECTIONS

Wire Number

Wire Color

Connects to:

1

Green/Yellow

Ground

2

Yellow

Water Valve

3

Black

Line

4

Light Blue

Neutral

IMPORTANT

PLEASE RETURN THIS SHEET TO IT’S ORIGINAL LOCATION.

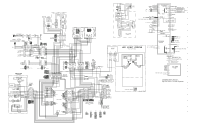

Ice Maker Errors Displayed on “UI”

Diagnostic Mode

Note:

See Service Manual for

complete description.

ERROR

Test

Activate: Hold FF (+) and FZ (+)

for 5 sec.

Ice

Er

IM/RAM Error

(on POR only)Detection – on POR

only. This error is detected as “no com/data link

with

IM”

by

ERF 2500++ system controller (PB).

48C

Freezer Recover Mode, “1” ok

“Fr” Recovery mode, Icemaker in

“off” state. (See Note)

57C

Fan test, on or off

Ice

IP

Invalid Protocol (this error is detected when the

version of I/M pcb does not match version of 2500++

system controller)

49C

EEV On=Open Off=Closed , EEV

must be in the open state for sealed

system evacuation.

58C

Ice level sensor switch test

Ice

CE

IM Com Lost only after POR(no communication

between the I/M pcb and the 2500++ system

controller.)

50C

Com Link “1” ok “ER” error

59C

Fill limit switch test

(See Note)

Ice

t3

TH3 Error (open or short) This error is detected

when the thermister has failed on the suction line

of the I/M.

51C

TH1 Status “1” ok

“ER” Replace

60C

Freeze limit switch test

(See Note)

52C

TH3 Status “1” ok

“ER” Replace

61C

IM evap heater test

54C

Mold heater test, on or off

62C

EEV test

56C

Finger evap heater, on or off

63C

Harvest motor system test

(See Note)

55C

Water valve test (See Note)

64C

Software version

De-activate: Hold FF (+) for 5 sec.

System Error Codes Displayed on “UI”

Diagnostic Mode

Note:

See Service Manual for

complete description.

ERROR

Test

Activate: FZ (+) and FZ (-) for

5 sec.

OP or 2

Freezer Sensor OPEN

1

Standard compressor

22

Damper

SH or 3

Freezer Sensor SHORTED

2

Defrost heater

23

Fresh food door

OP or 2

FF Sensor OPEN

3

FF lighting

24

Freezer door

SH or 3

FF Sensor SHORTED

8

Water valve,water disp.

26

Defrost limit switch

SY

EF

Evaporator Fan Circuit

9

FZ lighting

28

Dispenser paddle

SY

CE

Communication error

10

Auger motor

36

Ice door

SY

CF

Communication error

11

Cube/crush solenoid

29

FF Thermistor

dF

In Manual Defrost

41

Perfect Temp Drawer

30

FZ Thermistor

12

VCC Condensor fan

33

Ambient Thermistor

To initiate manual defrost press and hold,

for 5 sec. FF(+) and FF(-),

(d) and (f)

will be displayed.

38

VCC Compressor

0-

Software version

15

Evaporator fan

De-activate: Hold FF (+) for 5 sec.

FF Ice Maker

(2419801)

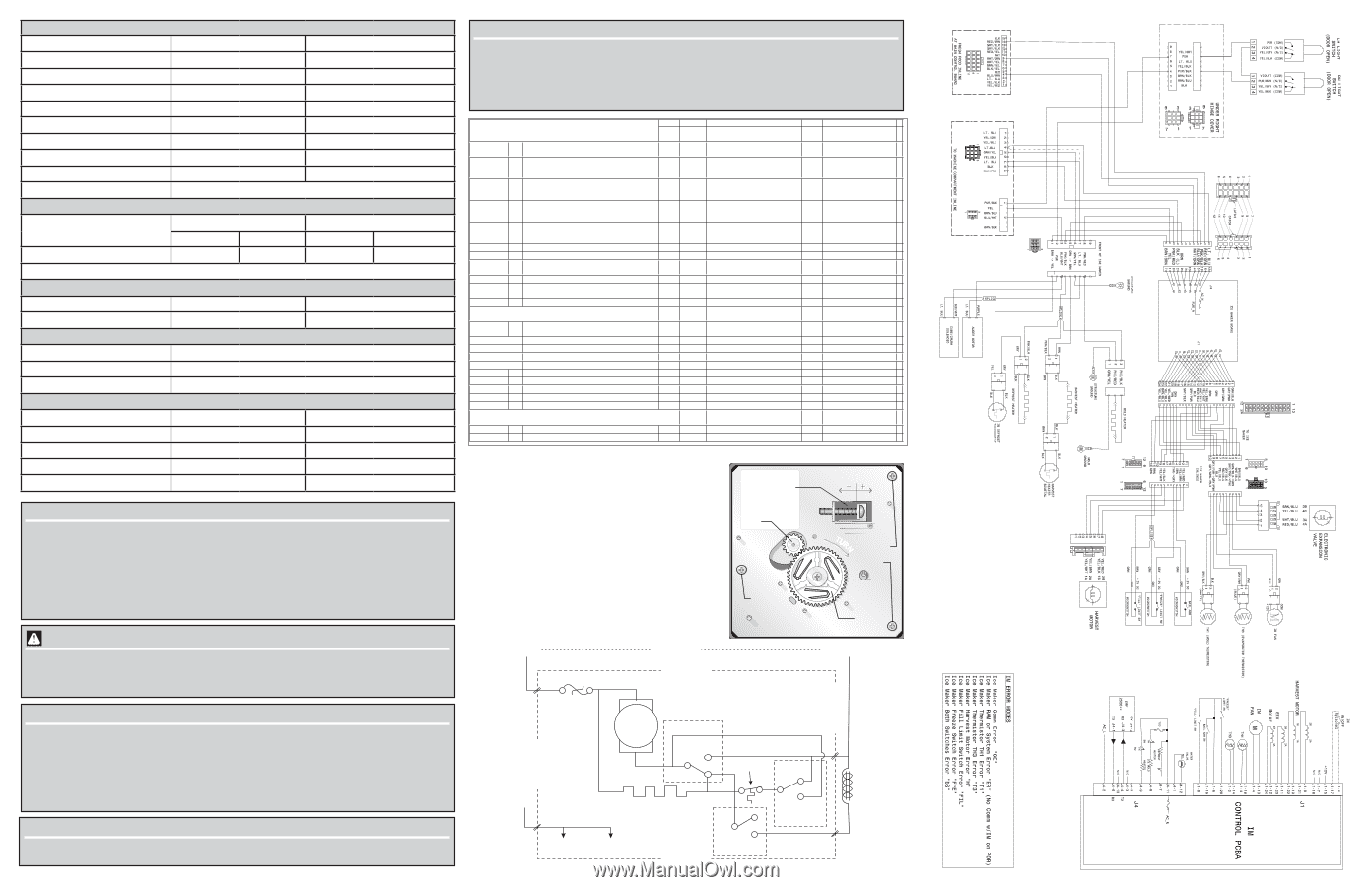

FREEZER ICE MAKER INFORMATION

Test Cycling:

Remove cover by inserting

screwdriver in notch at

bottom and prying cover

from housing. Use screwdriver to rotate motor

gear counterclockwise until holding switch circuit

is completed. All components of ice maker should

function to complete the cycle.

Water Fill Volume:

The water fill adjust

-

ment screw will change the fill time. One full turn

is equal to 20cc (.68 oz.). The correct fill is 102

to 130cc (3.4 to 4.3 oz.). When a water valve is

replaced, the fill volume must be checked.

T

U

R

N

Mounting

Plate

Screws

Mounting

Plate

Screw

Motor

Gear

Timing

Gear

Water Fill

Adjustment

POWER

ICE MAKER

I

CE MAKER

ICE

MAKER

WA

TER VALVE

LINE

THERMAL

CUT-OUT

HOLD

SWITCH

THERMOSTAT

SHUT-OFF

SWITCH

WATER FILL

SWITCH

MOLD HEATER

MOLD

MOUNTING

PLATE

165 WATTS

MOTOR

NEUTRAL

BLK

BLK

BLK

BLK

BLU

C

C

C

NO

NO

NO

NC

NC

NC

LT. BLU

LT

. BLU

BRN

RED

GRN / YEL

GRN / YEL

RED

RED

YEL

YEL

YEL

P-3

P-1

P-2

P-4

ICE MAKER