Hayward Power-Flo LX SP1575X15

Hayward Power-Flo LX Manual

|

View all Hayward Power-Flo LX manuals

Add to My Manuals

Save this manual to your list of manuals |

Hayward Power-Flo LX manual content summary:

- Hayward Power-Flo LX | SP1575X15 - Page 1

replace as necessary. 2. Hayward Pumps have self-lubricating motor bearings and shaft seals. No lubrication is necessary. 3. Keep motor clean. Insure that vents are free from obstruction. 4. Shaft seals must be replaced occasionally, due to wear or damage. See instructions. STORAGE/WINTERIZING Pump - Hayward Power-Flo LX | SP1575X15 - Page 2

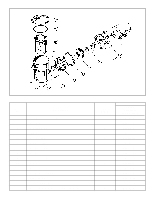

Cover Housing Gasket Impeller Seal Assembly Pump Housing Nut, No. 10-24 Hex. Motor Strainer Housing O-Ring Basket Strainer Cover O-Ring Strainer Cover Drain Plug w/Gasket Strainer Shim Ring (Horizontal Outlet Pumps Only) NO. REQ'D. 7 1 1 1 1 1 7 1 1 1 1 1 1 2 1 PART NUMBER MODEL SP1575X15 (With - Hayward Power-Flo LX | SP1575X15 - Page 3

power before performing service or maintenance. 1. Remove pump and motor assembly from piping system. 2. Remove pump housing cover (with strainer attached) by removing the seven (7) housing bolts and nuts which fasten housing cover to pump housing. The impeller is now exposed. 3. To remove impeller - Hayward Power-Flo LX | SP1575X15 - Page 4

housing. 5. Motor bearings made unserviceable by wear, rust, or continual overheating. SERVICE & REPAIRS Consult your local authorized Hayward Dealer or service center. No pumps or motors may be returned directly to the factory without the expressed written authorization of Hayward Pool Products

IS1575X15-00

HAYWARD HIGH PERFORMANCE PUMPS

INSTALLATION AND OPERATING INSTRUCTIONS

Your Hayward centrifugal pump has been quality-built

and engineered to give you many years of efficient,

dependable service.

The advanced design reduces required maintenance

to simple, common-sense procedures.

HAYWARD POOL PRODUCTS, INC.

900 FAIRMOUNT AVENUE, ELIZABETH, NEW JERSEY 07207

GENERAL TIPS ON PUMP INSTALLATION

For best pump performance, locate the system

below the pool water line and as close to the pool

as practical.

If you own an above-ground pool,

please see Note: NSPI-4, Article V, for safe and

proper installation of the equipment package

.

Make sure suction joints are tight. Suction pipe

should be as large or larger than discharge pipe.

Damp, non-ventilated locations should be avoided.

Motors require free circulation of air to aid in

cooling.

Insure that the electrical supply available agrees

with the motor’s voltage, phase and cycle, and that

wire size is adequate for the motor’s HP (KW)

rating and distance from power source. Motor

must always be properly grounded. If cord

connected,

use

only

a

properly-grounded

receptacle.

Electrical circuits must be protected

by proper size ground fault circuit interrupter

(GFCI) as required by applicable electrical codes.

All electrical wiring must be performed by qualified

personnel, and must conform to local codes and

regulations.

STARTING AND PRIMING INSTRUCTIONS

Fill strainer housing with water to suction pipe

level. Never operate the pump without water.

Water acts as a coolant and lubricant for the

mechanical shaft seal.

Open all suction and discharge lines and valves,

as well as manual air relief valve (if available) on

filter. (The air that is to be displaced from the

suction line must have some place to go.)

CAUTION: All suction and discharge valves

must be open when starting the system.

Failure to do so could cause severe personal

injury and/or property damage.

Turn on power and allow a reasonable time for

priming. Priming time depends on suction lift and

horizontal length of suction piping. If the pump will

not start, or will not prime, see TROUBLE

SHOOTING GUIDE on back page.

NOTE: NSPI-4 Article V, standard for above-

ground and on-ground pools, advises that

components such as the filtration system,

pumps and heater be positioned so as to

prevent their being used as a means of access

to the pool by young children.

MAINTENANCE

Clean strainer basket regularly. Do not strike

basket to clean. Inspect strainer cover gasket

regularly and replace as necessary.

Hayward Pumps have self-lubricating motor

bearings and shaft seals. No lubrication is

necessary.

Keep motor clean. Insure that vents are free

from obstruction.

Shaft seals must be replaced occasionally, due

to wear or damage. See instructions.

STORAGE/WINTERIZING

Pump and motor must be protected from freezing.

Shut off all electric power. Disconnect electrical

and plumbing connections. Drain thoroughly and

clean out any debris. Store pump and motor in a

dry, well-ventilated room.

1.

2.

3.

4.