Hoover F4300 Manual - Page 6

Waxing floors - pads

|

View all Hoover F4300 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

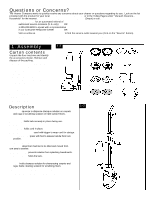

Waxing floors There are two types of wax to use on hard surface floors: water-base and solvent-base. 2-9 1. Water-base wax Water-base wax is a self-polishing wax which does not contain a petroleum solvent. It can be used on all hard surface floors except wood. Follow the directions on the container to apply. Do not polish or buff this wax. 2. Solvent-base wax Solvent-base wax can be identified by the caution statement: "Flammable" or "Combustible" on the label. It is used on wood floors and can be polished and buffed when dry. Do not use solventbase wax on asphalt or rubber tile or other hard surface floors unless specified by the manufacturer. There are two kinds of solvent-base wax: paste wax and liquid cleaning-polishing wax. 2-10 Paste Wax Solvent Base Floor Wax Solvent Base a. Paste wax To spread wax evenly, attach power scrub and cleaning brushes to floor machine and snap on heavy duty cleaning and waxing pads. Spread a thin coat of wax on pads or spread a small amount on floor with spatula. Start by pressing handle release lever and lowering handle. Apply wax to floor, by guiding in straight lines or with grain of the wood, until the wax is spread evenly. b. Cleaning-polishing wax This type of wax is used to clean as well as wax floors. Apply wax according to instructions on the container. Use the floor machine only to polish floors when this type of wax is used. Refer to section "Cleaning floors-Solvent cleaning wax method". 2-11 Polishing and buffing floors Floors waxed with solvent-base wax may be polished and buffed with the floor machine. 1. Be sure wax is thoroughly dry before polishing. This usually takes 20-30 minutes but may take longer in damp weather. 2. Use power scrub and cleaning brushes to polish floor. Press handle release and start by lowering handle. Guide the floor machine in straight lines or with the grain of the wood. 3. A double coat of wax will give floors more protection. Let wax dry thoroughly and polish after each application. To achieve a high luster finish 1. Attach felt buffing pads over power scrub and cleaning brushes using fasteners. Polish to a soft shine by guiding floor machine in straight lines or with the grain of the wood. If more shine is desired proceed to step 2. 2. Remove felt buffing pads and attach high luster pads (available at additional cost). Once again, guide the handle in straight lines or with the grain of the wood to achieve a high luster finish. To keep floors bright and shiny Floor should be buffed frequently to restore sheen and remove scratches and marks. This lengthens the time between waxings. Before buffing, use a vacuum cleaner to remove dust and dirt and damp cloth to remove sticky particles. Stubborn spots, such as black heel marks, can be removed by rubbing gently with very fine steel wool dampened with wax. If traffic areas need to be rewaxed and polished, and a solvent-base wax has been used on the floor, apply wax only to these areas then buff the entire floor. 6