Kyocera KM-1820 1820 Operation Guide (Advanced Edition) - Page 123

Selecting the Right Paper, Condition of the Paper, Composition - print cleaning

|

View all Kyocera KM-1820 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 123 highlights

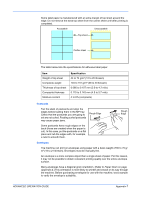

Item Dimensional accuracy Squareness of corners Moisture content Direction of grain Pulp content Specification ±0.7 mm (±0.0276 inches) 90° ±0.2° 4% to 6% Long grain 80% or more Selecting the Right Paper Laser printing is a process involving laser light, electrostatic discharge, toner, and heat. In addition, as the paper passes through the machine it undergoes considerable sliding, bending, and twisting motions. A high-quality printing paper matching the machine's requirements withstands all these stresses, enabling the machine to turn out clean, crisp printed copies consistently. Remember that all paper is not the same. Some of the factors to consider when selecting paper for the machine are as follows: Condition of the Paper Avoid using paper that is bent at the edges, curled, dirty, torn, embossed, or contaminated with lint, clay, or paper shreds. Use of paper in these conditions can lead to illegible printing, misfeeding, and paper jams, and can shorten the life of the machine. In particular, avoid using paper with a surface coating or other surface treatment. The paper should have as smooth and even a surface as possible. Composition Do not use paper that has been coated or surface-treated and contains plastic or carbon. The heat of fusing can cause such paper to give off harmful fumes. Bond paper should contain at least 80% pulp. Not more than 20% of the total paper content should consist of cotton or other fibers. Appendix-2 ADVANCED OPERATION GUIDE