LG LFX31925ST Owner's Manual - Page 20

Water Line Installation Instructions - not making enough ice

|

View all LG LFX31925ST manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 20 highlights

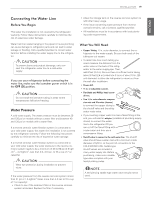

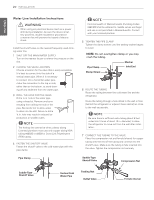

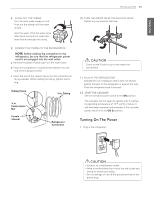

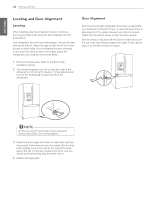

20 INSTALLATION ENGLISH Water Line Installation Instructions WARNING When using any electrical device (such as a power drill) during installation, be sure the device is battery powered, double insulated or grounded in a manner that will prevent the hazard of electric shock. Install the shutoff valve on the nearest frequently used drinking water line. 1 SHUT OFF THE MAIN WATER SUPPLY Turn on the nearest faucet to relieve the pressure on the line. 2 CHOOSE THE VALVE LOCATION Choose a location for the valve that is easily accessible. It is best to connect into the side of a vertical water pipe. When it is necessary to connect into a horizontal water pipe, make the connection to the top or side, rather than at the bottom, to avoid drawing off any sediment from the water pipe. 3 DRILL THE HOLE FOR THE VALVE Drill a ¼ in. hole in the water pipe using a sharp bit. Remove any burrs resulting from drilling the hole in the pipe. Be careful not to allow water to drain into the drill. Failure to drill a ¼ in. hole may result in reduced ice production or smaller cubes. Note The hookup line cannot be white, plastic tubing. Licensed plumbers must use only copper tubing NDA tubing #49595 or 49599 or Cross Link Polyethylene (PEX) tubing. 4 FASTEN THE SHUTOFF VALVE Fasten the shutoff valve to the cold water pipe with the pipe clamp. Pipe Clamp Note Commonwealth of Massachusetts Plumbing Codes 248CMR shall be adhered to. Saddle valves are illegal and use is not permitted in Massachusetts. Consult with your licensed plumber. 5 TIGHTEN THE PIPE CLAMP Tighten the clamp screws until the sealing washer begins to swell. NOTE: Do not overtighten clamp or you may crush the tubing. Pipe Clamp Washer Inlet End Clamp Screw 6 ROUTE THE TUBING Route the tubing between the cold water line and the refrigerator. Route the tubing through a hole drilled in the wall or floor (behind the refrigerator or adjacent base cabinet) as close to the wall as possible. Note Be sure there is sufficient extra tubing (about 8 feet coiled into 3 turns of about 10 in. diameter) to allow the refrigerator to move out from the wall after installation. 7 CONNECT THE TUBING TO THE VALVE Place the compression nut and ferrule (sleeve) for copper tubing onto the end of the tubing and connect it to the shutoff valve. Make sure the tubing is fully inserted into the valve. Tighten the compression nut securely. Saddle-Type Shutoff Valve Compression Nut Saddle-Type Shutoff Valve Vertical Cold Water Pipe Packing Nut Outlet Valve Ferrule (sleeve)