Lexmark E460 IPDS Emulation User's Guide - Page 56

Lexmark X860de, X862de and X864de MFPs Optional Advanced Finisher Functions

|

View all Lexmark E460 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 56 highlights

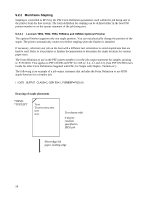

5.2.1.3 Lexmark X860de, X862de and X864de MFPs Optional Advanced Finisher Functions The Lexmark X860de, X862de and X864de MFPs supports a Standard Finisher and an Advanced Finisher. The Advanced Finisher supports Corner staple, Dual staple (IPDS Edge stitch with 2 staples), Center Fold (IPDS Center Fold-in), and Saddle staple (IPDS Saddle stitch-in). The printer automatically rotates the text 180 degrees for short-edge fed paper and 90 degrees for long-edge fed paper. If necessary, reformat your job on the host with a different text orientation to avoid stapled or folded sets that are hard to read. Finishing functions may not be applied to all paper sizes. Refer to your printer or finisher documentation to determine the finishing support and staple location for various paper sizes. The Printer device type must always be *IPDS. How to specify the Printer File parameters for Center Fold, and Saddle staple is shown below. Examples for Corner staple and Dual staple are in section 5.2.1.2 on page 54. 5.2.1.3.1 Center Fold (IPDS Center Fold-in) Center Fold-in may be specified using various application programs using the Operation Type Center Fold-in (X'08' in the IPDS data stream). Center Fold-in folds the paper along the centerline of the paper with the printed side folded in. Center Fold-in is only supported on selected paper sizes. Refer to your printer or finisher documentation for the paper sizes supported. Center Fold-in is only supported on Letter and A4 paper when the paper is loaded for Short Edge Fed (SEF) printing. All jobs specifying Center Fold-in will be routed to the finisher physical bin 3. Center Fold-in has a higher priority than bin selection, offset, and hole punch. These functions will be ignored when specified with Center Fold-in. 5.2.1.3.2 Saddle Staple (IPDS Saddle stitch-in) Saddle staple may be specified using various application programs using the Operation Type Saddle stitch-in (X'12' in the IPDS data stream). Saddle stitch-in folds the paper inward (printed side in) along the centerline and places two staples in the centerline fold. Saddle stitch-in is only supported on selected paper sizes. Refer to your printer or finisher documentation for the paper sizes supported. Saddle stitch-in is only supported on Letter and A4 paper when the paper is loaded for Short Edge Fed (SEF) printing. All jobs specifying Saddle stitch-in will be routed to finisher physical bin 3. Saddle stitchin has a higher priority than bin selection, offset, and hole punch. These functions will be ignored when specified with Saddle stitch-in. Saddle stitch-in may be controlled by the following parameters in the Printer File Saddle stitch-in Reference edge LEFT or *DEVD Reference edge offset..... *DEVD Number of staples......... *DEVD, Integer (see Number of staples below) Staple offsets DEVD 56