Lexmark X342N Service Manual - Page 38

First 6 bytes sub, error code data, can be any, value, Explanation, Possible, error, message - mfp laser

|

UPC - 734646256292

View all Lexmark X342N manuals

Add to My Manuals

Save this manual to your list of manuals |

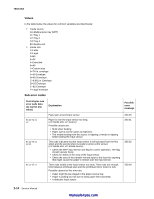

Page 38 highlights

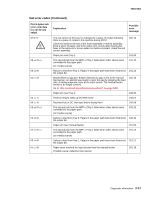

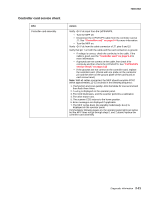

7003-XXX Sub error codes (Continued) First 6 bytes sub error code data (xx can be any value) 84 xx 2E 84 00 2F x1 x2 x3 84 xx 03 x1 84 xx 39 84 00 10 8D xx 00 84 xx 01 8D 00 01 00 00 00 89 xx 03 89 xx 04 x1 89 xx 0D Explanation Possible error message Failed no gap jam recovery. Engine detected no gap at the manual feeder 200.22 sensor. An attempt was made to open the gap by stopping the feed rolls, but never saw the leading edge of the second page at the input sensor. Laser servo never started due to potential conflict with the transfer servo. (x1=bit 0: transfer servo started, bit 1: transport started; x2+x3=transfer servo count value) Possible causes: Slow or missing transport motor positional feedback. 200.23 The measured gap between sheets of media at the input sensor is too small to meet video requirements. x1=time by which the gap was too small. 200.24 Mirror motor fell out of lock condition after paper at input sensor-more time elapsed since printhead expected stable lock time, but less than printhead jitter-stable specification. 200.27 Paper jam between input and exit sensor 201.00 The main motor driver failed to detect a specific motor after two tries. Possible causes for this error are: • The main drive motor has stalled. • An incorrect main drive motor/gearbox assembly has been installed. 201.01 The fuser exit sensor was never activated by the leading edge of the media fed through the MFP. • This error can be displayed after a 201 paper jam. • This can be caused by a defective fuser exit sensor assembly. 201.02 Video never started on the page at the input sensor within 2 inches after 201.03 hitting the input sensor. User pressed Go or after an 8D xx 00 jam, but never opened the front 201.05 cover. Need to open cover and clear any media under cartridge before continuing. Paper jam around the exit sensor. 202.00 The fuser exit sensor did not detect the trailing edge of the media going through the fuser assembly. • This failure can be caused by a broken fuser exit sensor flag. • This may also be caused by erratic operation of exit sensor flag or exit sensor or a defective piece of media. 202.01 The fuser exit sensor never actuated from the sheet going through the fuser before the next page begins feeding. (x1=media size) 202.02 The fuser exit sensor bounced. Check the exit sensor for correct 202.06 operation. Check the sensor cable to J10 on the controller card. Also, the controller card may be failing. 2-16 Service Manual manuals4you.com