LiftMaster HCTDCU HCTDCU Quick Start Guide Manual

LiftMaster HCTDCU Manual

|

View all LiftMaster HCTDCU manuals

Add to My Manuals

Save this manual to your list of manuals |

LiftMaster HCTDCU manual content summary:

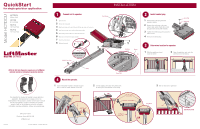

- LiftMaster HCTDCU | HCTDCU Quick Start Guide Manual - Page 1

Model HCTDCU QuickStart for single gate/door application HCTDCU Motor Unit HCT08 8 Foot Rail HCT10 10 Foot Rail HCT12 12 Foot Rail 2016 UL 325 Gate Operators require use of LiftMaster external monitored entrapment protection devices. This QuickStart is intended to highlight a single gate/door - LiftMaster HCTDCU | HCTDCU Quick Start Guide Manual - Page 2

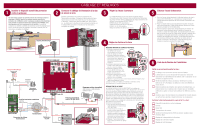

operator can be wired for 120 or 240 Vac by choosing the desired power wiring socket on the EMI board. Refer to your manual for complete wiring information. Set Open Speed The HCTDCU the TEST BUTTONS. 2. operator is left running on battery only, it will drain the battery and will result in a service - LiftMaster HCTDCU | HCTDCU Quick Start Guide Manual - Page 3

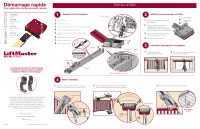

HCTDCU Moteur HCT08 Rail de 2,44 m (8 pi) HCT10 Rail de 3,05 m (10 pi) HCT12 Rail de 3,66 m (12 pi) Les actionneurs de barrière UL 325 2016 exigent l'utilisation de dispositifs externes surveillés de protection de LiftMaster le support de linteau dans l'ouverture et boulonner ou souder le support de - LiftMaster HCTDCU | HCTDCU Quick Start Guide Manual - Page 4

externe surveillé de protection de LiftMaster contre le piégeage (capteur instructions complètes de câblage. Régler la vitesse d'ouverture Le modèle HCTDCU des boutons de mise à l'essai (TEST BUTTONS). 2. Si la barrière/porte s'arrê qui entraînera un appel de service. Vérifier les batteries et leurs - LiftMaster HCTDCU | HCTDCU Quick Start Guide Manual - Page 5

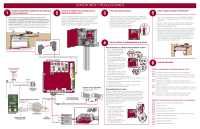

HCTDCU Motor HCT08 Guía de 8 pies HCT10 Guía de 10 pies HCT12 Guía de 12 pies Con los operadores de portón UL 325 2016 es necesario utilizar dispositivos externos monitoreados de protección de LiftMaster de cadena. Tensor 7 Parte superior de guía Tuerca hexagonal bolsa con el manual). 3 Ajustar el - LiftMaster HCTDCU | HCTDCU Quick Start Guide Manual - Page 6

pero ES NECESARIO instalar otra protección externa monitoreada de LiftMaster para CADA zona de atrapamiento (sensor fotoeléctrico sin la tarjeta EMI. Consultar el manual para obtener las instrucciones completas de cableado. Fijar velocidad de apertura El HCTDCU ofrece la opción de apertura

1

3

4

5

6

2

7

1

Open the cover.

2

Remove the chain guard.

3

Align the key holes on the end of the rail with the cap screws on the chassis.

4

Attach the rail to the chassis with the hardware provided.

5

Move trolley to within 3 feet (.9 m) of the end of the rail.

6

Wrap the chain around the output sprocket.

7

Adjust the chain tension.

8

Replace chain guard.

This QuickStart is intended to highlight a single gate/door

application. Each application is unique and it is the

responsibility of the purchaser, installer and end user to ensure

that the total gate/door system is installed and operated

properly. Refer to the installation manual for complete

information regarding installation, testing, and programming.

QuickStart

for single gate/door application

Model HCTDCU

INSTALLATION

01-38474

© 2016, LiftMaster – All Rights Reserved

845 Larch Avenue

Elmhurst, Illinois 60126-1196

LiftMaster.com

Connect rail to operator.

Install vented plug.

Determine location for operator.

Mount the operator.

2016 UL 325 Gate Operators require use of LiftMaster

external monitored entrapment protection devices.

HCTDCU

Motor Unit

HCT08

8 Foot Rail

HCT10

10 Foot Rail

HCT12

12 Foot Rail

Temporary

Support Post

Header Bracket

Vented Plug

Header Bracket

OR

Concrete Anchor

1/2" x 3 1/2"

Brackets (not provided)

Flush Mount

Arm

Door Arm

DOOR INSTALLATION

Cap Screw

Chain Guard

Trolley

Within 3 feet (.9 m)

Top of Rail

1/4" (.64 cm) Max.

Turnbuckle

Hex Nut

Carriage Bolt

Nut

Washer

1

Center the header bracket in the opening and

bolt or weld the header bracket to the wall.

2

Lift the operator and align with center mark

on ceiling. Bolt the operator to the ceiling.

3

Bolt or weld arm to gate/door.

1

With the gate/door closed,

mark the center.

1

Remove the dome plug from the

operator chassis.

2

Remove the solid plug in the gear

reducer and replace it with the vented

plug (provided in bag with manual).

3

Tighten the vented plug with a socket or

Allen wrench.

4

Re-insert the dome plug.

2

Open the gate/door and mark the

center point on the ceiling.

Dome Plug