LiftMaster J J VERSION 2 LOGIC Manual

LiftMaster J Manual

|

View all LiftMaster J manuals

Add to My Manuals

Save this manual to your list of manuals |

LiftMaster J manual content summary:

- LiftMaster J | J VERSION 2 LOGIC Manual - Page 1

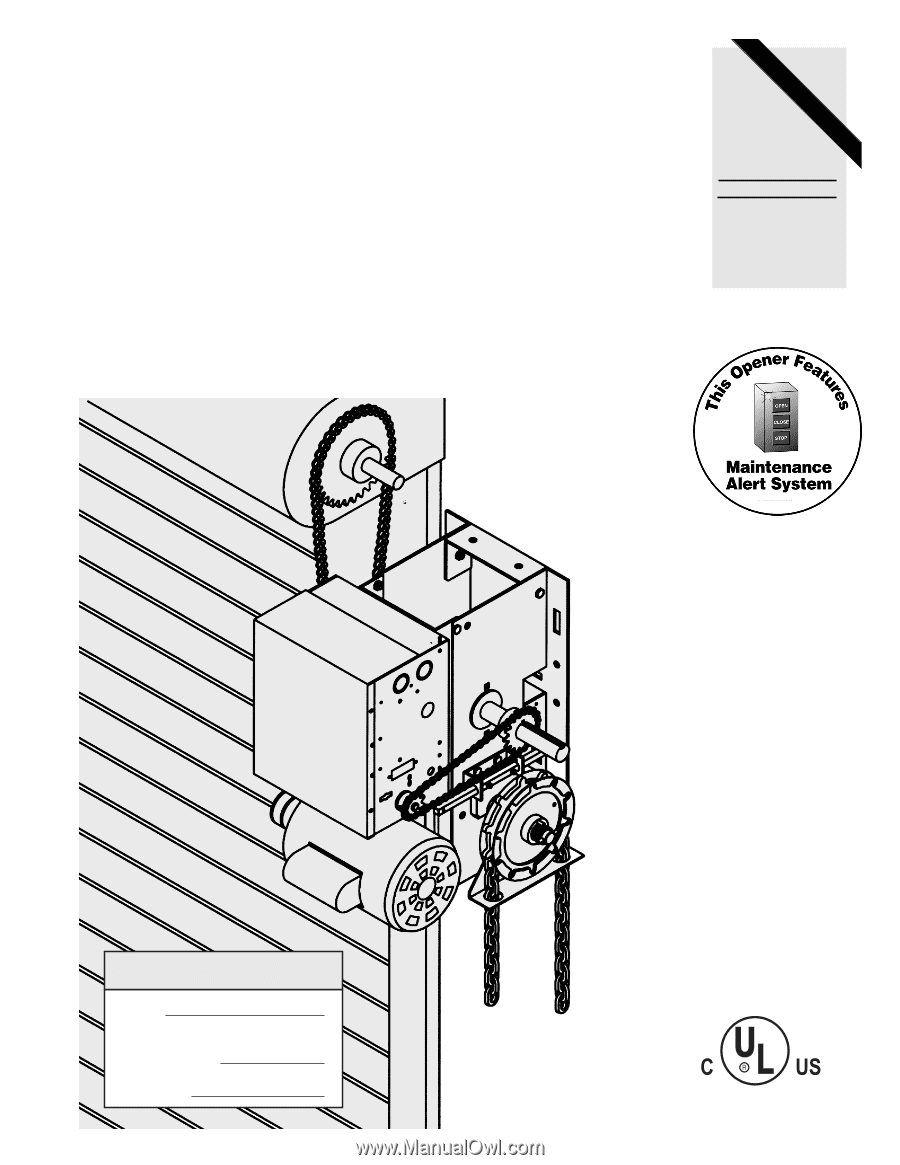

OWNER'S MANUAL MODELS: J ✦ H ✦ HJ LOGIC CONTROL (VER. 2.0) INDUSTRIAL DUTY DOOR OPERATOR LOGIC LCONTROL FACTORY SET C2 will signal when the set number of cycles is reached or when the opener requires immediate service. 2 YEAR WARRANTY Serial # (located on electrical box cover) Installation Date - LiftMaster J | J VERSION 2 LOGIC Manual - Page 2

SIGHT OF DOOR OR ANY OTHER CONTROL (AUTOMATIC OR MANUAL) IS USED. PHOTO EYES Interface directly to LiftMaster CPSII. WEIGHTS AND DIMENSIONS HANGING WEIGHT: .........80-110 LBS. 14.50" 7.25" 17.63" 14.60" 4.63" 4.41" MOUNTING DIMENSIONS A - Wall Mounting B - Bracket Mounting (rolling door) 7.50 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 3

HJ with manual hoist hand chain systems, the handing of the operator must be determined at the time of order. The handing is indicated by last letter of the model name (R or L). The hand chain wheel can not be switched on site. If your installation causes the hand chain to hang in the door opening - LiftMaster J | J VERSION 2 LOGIC Manual - Page 4

9098 Optimum Distance 12 - 15" Optimum Distance 12 - 15" Typical Right Hand Wall Mounted Operator FIGURE 3 IMPORTANT: The shelf or bracket must provide adequate support, prevent play between operator and door shaft, and permit operator to be fastened securely and with the drive shaft parallel to - LiftMaster J | J VERSION 2 LOGIC Manual - Page 5

HJ Keyhole Bracket Model HJ This operator includes both a floor level disconnect chain to disconnect the door from the door operator and and a disconnect chain with manual hoist to electrically disable the operator controls. 1. Refer to Model H instructions for hoist operation. 2. Refer to Model - LiftMaster J | J VERSION 2 LOGIC Manual - Page 6

have a bottom sensing edge and you wish to purchase one, contact the supplier of your operator. If not pre-installed by the door manufacturer, mount the sensing edge on the door according to the instructions provided with the edge. The sensing edge may be electrically connected by either coiled cord - LiftMaster J | J VERSION 2 LOGIC Manual - Page 7

power supply will cause the motor to rotate in the wrong direction (open when CLOSE button is pressed and vice-versa). To correct this, interchange any two of the incoming three phase power lines. 1-1/16" dia. Power Wiring Access Hole (2 Near Side) 7/8" dia. Control Wiring Access Hole (Far Side - LiftMaster J | J VERSION 2 LOGIC Manual - Page 8

type) may be mounted to this bracket. The operator will then open a fully closed door, close a fully open door, and reverse a closing door from the radio transmitter. However, for complete door control from a transmitter, a commercial three-channel radio set (with connections for OPEN/CLOSE/STOP) is - LiftMaster J | J VERSION 2 LOGIC Manual - Page 9

brake is optional on all models, and is optional on 1/3 and 1/2 horsepower models. The brake is adjusted at operator to move the door smoothly but to allow the clutch to slip if the door is obstructed. When the clutch is properly adjusted, it should generally be possible to stop the door by hand - LiftMaster J | J VERSION 2 LOGIC Manual - Page 10

LOGIC CONTROL (VER. 2.0) 1 PHASE WIRING DIAGRAM 1837-1 MOTOR 115V 1 PHASE MOTOR 230V 1 PHASE TO REVERSE MOTOR DIRECTION 115 VOLT: REVERSE BLUE AND YELLOW WIRES. 208-230 VOLT: REVERSE PURPLE AND GRAY WIRES. 10 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 11

LOGIC CONTROL (VER. 2.0) 3 PHASE WIRING DIAGRAM 1837-3 MOTOR 230V 3 PHASE MOTOR 380/460V 3 PHASE TO REVERSE MOTOR DIRECTION REVERSE PURPLE AND GRAY WIRES 11 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 12

STANDARD POWER & CONTROL CONNECTION DIAGRAM Logic Control Board (VER. 2.0) - 115V, 208, 230V, 1Ph 12 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 13

STANDARD POWER & CONTROL CONNECTION DIAGRAM Logic Control Board (VER. 2.0) - 208, 230V, 380V, 460V, 3Ph 13 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 14

SETTINGS Logic Control Pushbuttons Open, Close, Stop Open, Close and Stop buttons are mounted directly on the Logic Control board. This will provide easy programming ability and door control at the electrical box. Programmable Maximum Run Timer: Any time a "closing" or "opening" door takes 10 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 15

PCB BOARD ILLUSTRATION RPM LEARN BUTTON HEAT SINK POWER WIRING TERMINAL BLOCK DIP SWITCH CONTROL WIRING TERMINAL BLOCK OPEN, CLOSE, STOP BUTTON 15 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 16

of clutch slippage. External interlocks and auxiliary devices. Open button override while door is traveling down. NOTE: Open, Close, and Stop buttons are located on the Logic Control board. This will provide programming ability and door control at the electrical box. WIRING TYPE STATION C2 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 17

mounting wiring types: These wiring types require the use of self monitoring sensing devices. (The optional Lift Master CPSII photoeye package) TYPE STATION C2 Failsafe 3 Button, 3 Button Radio Control ON Same functions as C2. Failsafe safety device must be installed to operate door LiftMaster - LiftMaster J | J VERSION 2 LOGIC Manual - Page 18

reset except in the case where the Motor or Logic Control board has been replaced and only if the motor doesn't have a start switch. Set unit to any normal mode, B2 is suggested. Begin with the door in the open or closed position. Set the limit switches so the operator can run for at least 5 seconds - LiftMaster J | J VERSION 2 LOGIC Manual - Page 19

Manual Disconnect Check & Operate motor. Motor bearings are rated for continuous operation. I Do not lubricate clutch or V-belt. I Inspect and service whenever a malfunction is observed or suspected. I CAUTION: BEFORE SERVICING, ALWAYS DISCONNECT OPERATOR FROM POWER SUPPLY. HOW TO ORDER REPAIR PARTS - LiftMaster J | J VERSION 2 LOGIC Manual - Page 20

ILLUSTRATED PARTS - ELECTRICAL BOX S6 S5 S3 S7 S2 S1 S8 S4 S9 6 7 8 L5 L8 2 L6 L2 5 L3 L1 4 L7 L3 L8 L9 4 5 1 3 L2 L6 L4 9 10 20 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 21

REPAIR PARTS KITS - ELECTRICAL BOX LOGIC CONTROL (VER. 2.0) Below are replacement kits available for your operator. For replacement of electrical box, motor or brake components be sure to match model number of your unit to kit number below to ensure proper voltage requirements. Optional - LiftMaster J | J VERSION 2 LOGIC Manual - Page 22

ILLUSTRATED PARTS - Model J 5 6 7 1 8 9 C8 C20 C10 C9 D1 D7 D4 D8 D11 D3 C21 D10 D9 D2 D5 D6 C4 C6 C24 C7 C16 C23 C17 C14 C18 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 23

REPLACEMENT PARTS KITS - MODEL J LOGIC CONTROL (VER. 2.0) Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or accessories are included with your operator, certain components may be added or remove from these lists. Individual components - LiftMaster J | J VERSION 2 LOGIC Manual - Page 24

ILLUSTRATED PARTS - Model H 5 6 7 1 D1 D10 D7 D4 D9 8 D8 D11 D3 C12 D2 D5 D6 C15 C6 C2 C17 C5 C16 C4 C18 C7 C19 C18 C25 C19 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 25

REPLACEMENT PARTS KITS - MODEL H LOGIC CONTROL (VER. 2.0) Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or accessories are included with your operator, certain components may be added or remove from these lists. Individual components - LiftMaster J | J VERSION 2 LOGIC Manual - Page 26

ILLUSTRATED PARTS - MODEL HJ 26 8 5 6 1 7 L1 L7 L4 L10 L9 L8 L11 L3 C17 L2 L5 L6 C7 C2 C20 C6 C5 C22 C23 C30 C14 C19 O10 O5 - LiftMaster J | J VERSION 2 LOGIC Manual - Page 27

REPLACEMENT PARTS KITS - MODEL HJ LOGIC CONTROL (VER. 2.0) Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or accessories are included with your operator, certain components may be added or remove from these lists. Individual - LiftMaster J | J VERSION 2 LOGIC Manual - Page 28

CONNECTION DIAGRAM 41B6 IMPORTANT NOTES: The 3-Button Control Station provided must be connected for operation. If a STOP button is not used, a jumper must be placed between terminals 4 and 5. LISTED DOOR OPERATOR 3 BUTTON STATION OR 3 POSITION KEYSWITCH WITH SPRING RETURN TO CENTER AND STOP - LiftMaster J | J VERSION 2 LOGIC Manual - Page 29

CONTROLS 1234 OPEN LIMIT SW. ROTATOR CUP RPM BOARD SAFETY LIMIT SW. 40-14329B ELECTRICAL BOX END VIEW LIMIT NUT Note: 1) See Owner's Manual for Dip Switch Functions and Programming Procedures 2) TO REVERSE MOTOR DIRECTION: INTERCHANGE PURPLE AND GRAY WIRES AT CONTACTOR #1 & 3. OPERATING - LiftMaster J | J VERSION 2 LOGIC Manual - Page 30

Logic Control (Ver. 2) 575 VOLT THREE PHASE W/ CONTACTOR 1897 DIP SWITCH SETTINGS PROGRAM SETTINGS ON MAX RUN TIMER 1 2 3 ADJUSTMENT Note: 1) TO REVERSE MOTOR DIRECTION: INTERCHANGE PURPLE AND GRAY WIRES AT CONTACTOR. CLOSE LIMIT SW. ROTATOR CUP DEPRESS PLATE OPEN LIMIT SW. ON C2 FAIL SAFE - LiftMaster J | J VERSION 2 LOGIC Manual - Page 31

ADDENDUM 575 Volt Logic 2 Operator MODELS: T and SD NOTE: Refer to addendum for Wiring Diagram and Electrical Box Replacement Parts, for all other installation instructions refer to owners manual shipped with operator. 575 VOLT THREE PHASE W/ CONTACTOR - LiftMaster J | J VERSION 2 LOGIC Manual - Page 32

ILLUSTRATED PARTS - ELECTRICAL BOX S6 S5 S2 7 2 S7 S1 S8 S4 S9 5 L3 L1 6 S3 L7 L9 L5 L8 L6 L2 L8 4 8 9 L2 L6 L4 10 1 3 3

OWNER'S MANUAL

MODELS:

J

✦

H

✦

HJ

LOGIC CONTROL (VER. 2.0)

INDUSTRIAL DUTY DOOR OPERATOR

Serial #

(located on electrical box cover)

Installation Date

Wiring Type

2

YEAR

WARRANTY

LOGIC CONTROL

L

C2 Wiring

FACTORY SET

See pages 16 thru 18

for other wiring

configurations

The Maintenance Alert System

allows the installer to set an internal

Maintenance Cycle Counter.

An LED

on the 3-button station will signal when

the set number of cycles is reached or

when the opener requires immediate

service.

TM

PATENT PENDING

NOT FOR RESIDENTIAL USE

LISTED

DOOR

OPERATOR

41B6