Makita MAC700 Owners Manual - Page 10

Initial Start Up Procedure, Extension Cords, Length of, Rating, Cord in Feet, Piping, Grounding - 2 h p air compressor

|

View all Makita MAC700 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

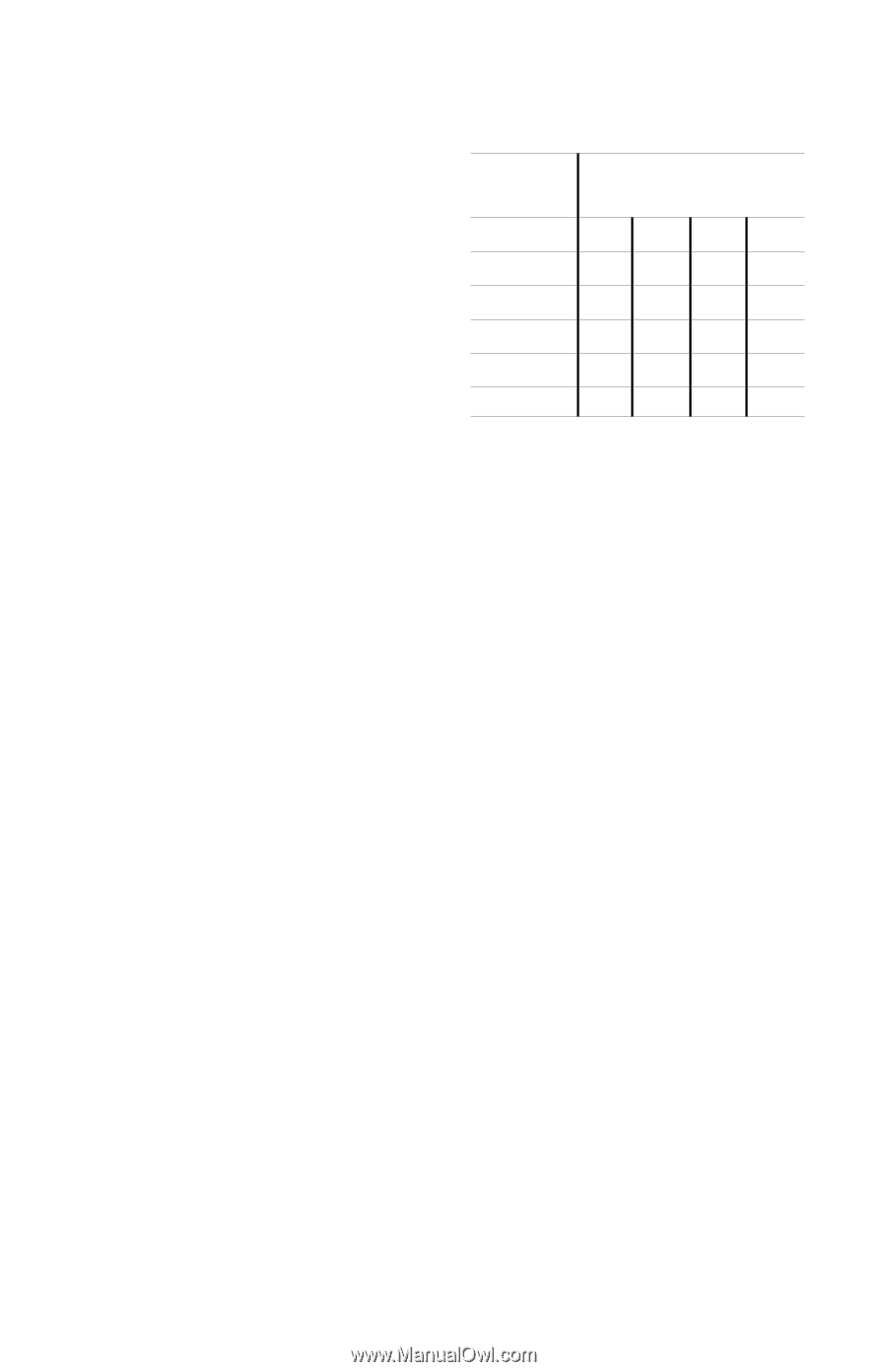

amount of oil may be present in the pump upon receipt of the air compressor. This is due to factory testing and does not mean the pump contains oil. CAUTION: Multi-Viscosity motor oils, like 10W 30, should not be used in an air compressor. They leave carbon deposits on critical components, thus reducing performance and compressor life. Use air compressor oil only. Initial Start Up Procedure: 1.Open the air receiver's drain valve. 2.Plug power supply cord into correct power source. 3.Run the compressor for a minimum of twenty (20) minutes in the no-load condition to lubricate the bearings and pistons, and to seat the piston rings. 4.Close air receiver drain valve. Your compressor is now ready for use. Extension Cords To avoid voltage drop, power loss, and overheating of the motor, use extra air hose instead of an extension cord. Low voltage can cause damage to the motor. If an extension cord must be used: · Use only an approved 3-wire extension cord that has a 3blade grounding plug and a 3slot receptacle that will accept the plug on the air compressor. · Make sure the extension cord is in good condition. Page 10 Please see the chart below as the MINIMUM requirements: Amp Rating Length of Cord in Feet (120 Volts) 25' 10-12 16 12-14 16 14-16 16 16-18 14 18-20 14 50' 100' 150' 14 10 8 12 10 8 12 10 8 12 8 8 12 8 8 Piping Plastic or PVC pipe is not designed for use with compressed air. Regardless of its indicated pressure rating, plastic pipe can burst from air pressure. Use only metal pipe for air distribution lines. If a pipe line is necessary, use pipe that is the same size, or larger than, the air tank outlet. Piping that is too small will restrict the flow of air. If piping is over 100 feet long, use the next larger size. Bury underground lines below the frost line and avoid pockets where condensation can gather and freeze. Apply pressure before underground lines are covered to make sure all pipe joints are free of leaks. Grounding Instruction WARNING: Risk of electric shock! In the event if a short circuit, grounding reduces the risk of shock by providing an escape wire for the electric current. This air compressor must be properly grounded. The air compressor is equipped with a cord having a grounding wire with an appropriate