Makita MAC700 Owners Manual - Page 13

Service, Instructions - lowes

|

View all Makita MAC700 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

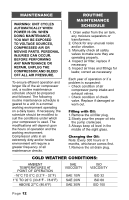

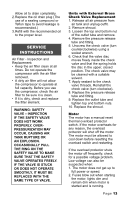

Allow oil to drain completely. 2.Replace the oil drain plug (The use of a sealing compound or Teflon tape to avoid leakage is recommended.) 3.Refill with the recommended oil to the proper level. SERVICE INSTRUCTIONS Air Filter - Inspection and Replacement: • Keep the air filter clean at all times. Do not operate the compressor with the air filter removed. • A dirty air filter will not allow the compressor to operate at full capacity. Before you use the compressor, check the air filter to be sure it is clean. • If it is dirty, check and replace the filter element. WARNING: SAFETY VALVE - INSPECTION IF THE SAFETY VALVE DOES NOT WORK PROPERLY, OVERPRESSURIZATION MAY OCCUR, CAUSING AIR TANK RUPTURE OR AN EXPLOSION. OCCASIONALLY PULL THE RING ON THE SAFETY VALVE TO MAKE SURE THAT THE SAFETY VALVE OPERATES FREELY. IF THE VALVE IS STUCK OR DOES NOT OPERATE SMOOTHLY, IT MUST BE REPLACED WITH THE SAME TYPE OF VALVE. Units with External Brass Check Valve Replacement 1. Release all air pressure from air tank and unplug outfit. 2. Remove shroud. 3. Loosen the top and bottom nut of the outlet tube and remove. 4. Remove the pressure release tube and fitting. 5. Unscrew the check valve (turn counterclockwise) using a socket wrench. 6. Check that the valve disc moves freely inside the check valve and that the spring holds the disc in the upper, closed position. The check valve may be cleaned with a suitable solvent. 7. Apply sealant to the check valve threads. Reinstall the check valve (turn clockwise). 8. Replace the pressure release tube and fitting. 9. Replace the outlet tube and tighten top and bottom nuts. 10. Replace the shroud. Motor The motor has a manual reset thermal overload protector switch. If the motor overheats for any reason, the overload protector will shut off the motor. The motor must be allowed to cool down before resetting the overload switch and restarting. If the overload protector shuts the motor off frequently, check for a possible voltage problem. Low voltage can also be suspected when: 1. The motor does not get up to full power or speed. 2. Fuses blow out when starting the motor; lights dim and remain dim when motor is started and is running. Page 13