Pfaff 28 Owner's Manual

Pfaff 28 Manual

|

View all Pfaff 28 manuals

Add to My Manuals

Save this manual to your list of manuals |

Pfaff 28 manual content summary:

- Pfaff 28 | Owner's Manual - Page 1

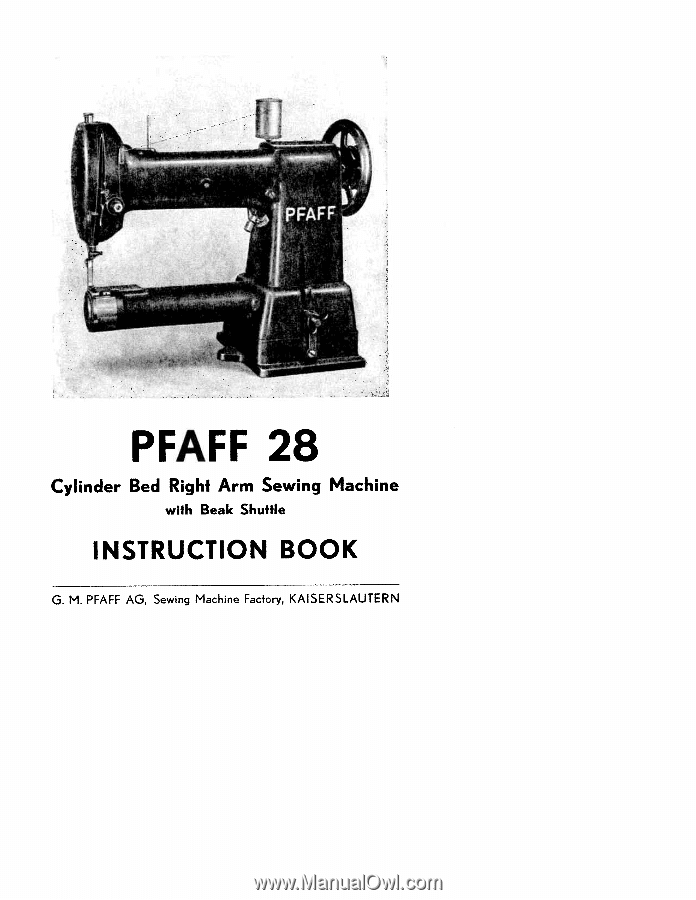

PFAFF 28 Cylinder Bed Right Arm Sewing Machine with Beak Shutt%e INSTRUCTION BOOK G. M. PFAFF AG, Sewing Machine Factory, KAISERSLAUTERN - Pfaff 28 | Owner's Manual - Page 2

FRiCTION Page 11 '"LEVER D FIGURE 8 - Pfaff 28 | Owner's Manual - Page 3

11 12. The Knee Lever Presser Foot Liftnr 12 13. Taking Out the Beak Shuttle 12 14. Tilting the Machine Over 13 15, Maintenance of the Machine 13 16. The Treadle Stand 15 17. Power Drive 15 18. Cylinder Bed Extensions 16 19. Probable Causes of Sewing Troubles inside back cover - Pfaff 28 | Owner's Manual - Page 4

Instruction Book PFAFF 28 Cylinder Bed Right Arm Sewing Machine Fitted with standard or extra large beak shuttle, link fake-up, knee lever presser foot lifter, reversible drop feed, wooden extension or iron screw-on work support for flat seaming oper ations, provided for foot, individual motor or - Pfaff 28 | Owner's Manual - Page 5

being released For delivery to the customer. 2. Engaging and Disengaging the Sewing Mechanism Two varieties of the PFAFF 28 are available: 1. with standard-size beak shuttle; 2. with extra large beak shuttle. Machines equipped with standard-size beak shuttles have a balance wheel with exchangeable - Pfaff 28 | Owner's Manual - Page 6

tension discs 3, through check spring 4, beneath guide 5, through eyelet 6, right-left through take-up 7, through eyelets 8 and 9, needle bar eyelet 10, and then left-right through needle eye 11. Note: As with all sewing machines, the needle of the PFAFF 28 is threaded in "long groove-short groove - Pfaff 28 | Owner's Manual - Page 7

4. Winding the Bobbin All PEAFF 28 machines are equipped with a table winder which hos proved very useful in all sewing shops. As shown in photo 3, place spool 1 on pin 2, and the empty bobbin on spindle 6. Pass the thread from spool 1 through the hole 3, between tenson - Pfaff 28 | Owner's Manual - Page 8

5. Changing the Bobbin and Threading the Bobbin Case Raise the shuttle race cop by slightly pushing it up with thumb and index finger of your left hand so that it can be slipped over the head of screw a (see photo 4), then let it hong by the hinge screw. Turn the balance wheel until the beak shuttle - Pfaff 28 | Owner's Manual - Page 9

under the presser foot. Basic Role: Stop the machine or commence sewing only with the take.up in its highest position. and bobbin threads should be locked in the center of the moteriol as shown in figure 10. Turning the tension nut M clockwise thread tension; turning it counter-clockwise sion (see - Pfaff 28 | Owner's Manual - Page 10

will decrease the tension. Since most of the stitching work done on the PFAFF 28 coIls not only for perfect but also for strong and durable seams, the locked in the cene oF the thickn,ss of he ma ter ia. F;g. 10 It is absolutely essential to use top-quality threads. Never use cheap threads of - Pfaff 28 | Owner's Manual - Page 11

bar will automatically release thu tension. 8. Regulating the Pressure on the Material According to the use for which they are intended, the PFAFF 28 sewing machines are fitted either with a roller presssr or with a presser foot. Proper feeding and even stitching as weil as preventing injury to the - Pfaff 28 | Owner's Manual - Page 12

sewing thicker leather are fitted with the longer flat-shank needle, System 80& Also this needle can be had with needle points R, P and LL. Variety PFAFF 28-8 A.B PFAFF 28-9 A B PFAFF 28 10 C D PFAF 2815 BC EFAFF 28-17 B PFAFF 28-17 C PFAFF 28-18 B PFAFF 28-18 C PFAFF 28-33 AB PFAFF 28-133AB PFAFF - Pfaff 28 | Owner's Manual - Page 13

- Needle and Thread Chart PFAFF Needle Size 8 10 11 12 13 14 15 16 17 18 19 Thread Weight Cotton Rayon Silk, continuous fiber Silk, staple , bandages, cowhide work shoe uppers, oiled cloths, leather garments heavyweight leather, football boots, footballs, mountain boots, light saddler work 10 - Pfaff 28 | Owner's Manual - Page 14

-shank needles, System 190 and 690, should present no problem if the following basic rule is observed: In all sewing machines, the short groove of the needle should face the shuttle. 11. Regulating the Length of Stitch the PFAFF 28 has its stitch regulator conveniently arranged under the arm. This - Pfaff 28 | Owner's Manual - Page 15

28-15, all PFAFF 28 machines are provid ed with a knee lifter which permits to raise and lower the roller presser or presser foot by knee control and allows the operator to rnaniouiate the work with both hands when performing intricate sewing shuttle race cap (as instructed in paragraph 5(, loosen - Pfaff 28 | Owner's Manual - Page 16

. 14. Tilting the Machine Over Compared with the obsolete PFAFF 23 and 25 Cylinder Bed Sewing Machines, the PFAF 28 features a considerable improvement in that its sturdy base is divided so as to permit tilting the machine back and rest(ng its head on the wooden support after loosening wing screw - Pfaff 28 | Owner's Manual - Page 17

has been tilted over inside the vertical part of the arm movable contact are to be oiled. (as instructed in poragroph 1 4), the are eosily occesstble (see photo 16). The machine will repay thorough cleaning and proper oiling with light running and perfect stitching. All should fluff that hos be - Pfaff 28 | Owner's Manual - Page 18

with same kerosene and to polish it with a soft cloth. Photo 18 16. The Treadle Stand Only in very rare cases will the PFAFF 28 be used as a foot driven machine exclusively. Maintenance of the treadle stand with the ball bearing pitnian rod is very simple. It is entirely sufficient to apply a drop - Pfaff 28 | Owner's Manual - Page 19

present no diffi culty. 18. Cylinder Bed Extensions Ia facilitate easy handling of the work for flat sewing, a wooden exten sion (see photo 19) is available at an extra charge for all PEAFF 28 machines. The dimensions of the cut-out in the polished metal plate are adapted to the different sub-class - Pfaff 28 | Owner's Manual - Page 20

19 Probable Causes of Sewing Troubles Skipping of Stitches: 1. Neede inserted incorrectly, grooves facing the wrong way. jamming in shuttle race. 6. Edges of needle hole damaged by the needle. Binding of Machine: 1. Driving belt too long. 2. Driving belt shortened too much. 3. Thread jamming in - Pfaff 28 | Owner's Manual - Page 21

KAISERSLAUTERN Founded 1862 Certificate of Guarantee For every PFAFF Sewing Machine bearing this TRADE MARK and the name PFAFF the factory assumes fu(I guarantee for first-class quality, efficiency, and durability. The Trade Mark and the name PFAFF are registered. All rights reserved. Nr. 9008

PFAFF

28

Cylinder

Bed

Right

Arm

Sewing

Machine

with

Beak

Shutt%e

INSTRUCTION

BOOK

G.

M.

PFAFF

AG,

Sewing

Machine

Factory,

KAISERSLAUTERN