Pfaff hobby 1142 Owner's Manual - Page 49

The cloth is not fed smoothly, Loops on the seams, The machine does not sew or run, The machine is - feet

|

View all Pfaff hobby 1142 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 49 highlights

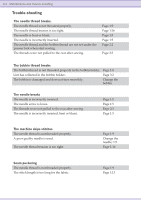

Maintenance and trouble-shooting 3:5 The cloth is not fed smoothly The feed dog is packed with lint. The stitches are too Àne. The feed dog is not raised after "drop feed" sewing. Loops on the seams The needle thread tension is too loose. Page 3:2 Page 1:13 Page 1:3 Page 1:16 The machine does not sew or run The machine is not plugged in. Thread has been caught in the hook race. The bobbin winder spindle is not returned to the left after bobbin winding. (Bobbin winding condition) The stitch density is not suitable for the fabric being sewn The machine is noisy Thread has been caught in the hook race. Lint has built up in the hook race or bobbin holder. Buttonhole is not sewn neatly The stitch density is not suitable for the fabric being sewn. Stabilizer is not used when sewing on the stretch fabrics. Layer slippage Foot pressure is not adjusted properly. Page 1:2 Page 3:2 Page 1:6 Page 1:14 Page 3:2 Page 3:2 Page 2:13 Use stabilizer Page 1:3 Important notes: Before changing presser feet and needle you must turn the main switch off. Do not attempt to sew without fabric under the presser foot. When leaving the machine, even for only a short time, switch off the main switch. This is important if there are any children nearby.