Rheem RAMP-JEZ Installation Instructions

Rheem RAMP-JEZ Manual

|

View all Rheem RAMP-JEZ manuals

Add to My Manuals

Save this manual to your list of manuals |

Rheem RAMP-JEZ manual content summary:

- Rheem RAMP-JEZ | Installation Instructions - Page 1

THESE INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH. (14.5 SEER MODELS & 14 OR 13 SEER MODELS IN CERTAIN MARKED SYSTEMS) ISO 9001:2000 DO NOT DESTROY THIS MANUAL PLEASE - Rheem RAMP-JEZ | Installation Instructions - Page 2

Tie-Down Method 7 Refrigerant Connections 8 Tools Required for Installing & Servicing R-410A Models 8 Specification of R-410A 8 Quick Reference for R- 16 High and Low Pressure Controls (HPC or LPC 18 Field Installed Accessories 18 Service 19 Trouble Shooting 20-22 Trouble Shooting Chart 23 - Rheem RAMP-JEZ | Installation Instructions - Page 3

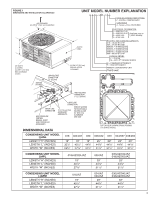

NUMBER EXPLANATION (-) A N L - 024 J A Z COOLING CONNECTION FITTING Z - SCROLL COMPRESSOR VARIATIONS A - Series = FULL FEATURED ACCESS PANEL ALLOW 24" [610 mm] SERVICE ACCESS CLEARANCE ELECTRICAL DESIGNATION J = 208/230V-1-60 } C = 208/230V-3-60 [Available only on D = 460V-3-60 (-)ANL- Models - Rheem RAMP-JEZ | Installation Instructions - Page 4

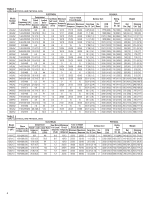

TABLE 1 (-)ANL ELECTRICAL AND PHYSICAL DATA ELECTRICAL PHYSICAL Model Number (-)ANL- Compressor Fuse or HACR Fan Motor Minimum Outdoor Coil Phase Rated Locked Full Load Circuit Circuit Breaker Frequency (Hz) Load Voltage (Volts) Amperes (RLA) Rotor Amperes (LRA) Amperes (FLA) Ampacity - Rheem RAMP-JEZ | Installation Instructions - Page 5

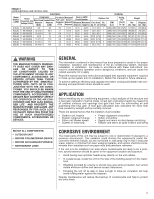

manual and any instructions packaged with separate equipment required to make up the system prior to installation. Retain this manual where contaminants are likely to be a problem, special attention should be given to but cannot violate minimum airflow and service access clearances. • Elevating the - Rheem RAMP-JEZ | Installation Instructions - Page 6

operating costs. • Locate the condenser where water run off will not create a problem with the equipment. Position the unit away from the drip edge of the and efficiency. Do not reduce the 60-inch discharge, or 24-inch service, clearances. • Do not obstruct the bottom drain opening in the condenser - Rheem RAMP-JEZ | Installation Instructions - Page 7

performance. Use the information in this Installation Instruction Manual and reference the applicable Engineering Specification Sheet FACTORY-PREFERRED TIE-DOWN METHOD FOR CONDENSING UNITS IMPORTANT: These instructions are intended as a guide to securing equipment for wind-load ratings of "120 MPH - Rheem RAMP-JEZ | Installation Instructions - Page 8

is to be made to prevent system contamination. TOOLS REQUIRED FOR INSTALLING & SERVICING R-410A MODELS Manifold Sets: -Up to 800 PSIG High side -Up to 250 PSIG Low Side -550 PSIG Low Side Retard Manifold Hoses: -Service Pressure Rating of 800 PSIG Recovery Cylinders: -400 PSIG Pressure Rating -Dept - Rheem RAMP-JEZ | Installation Instructions - Page 9

low-side with a 550 psig low-side retard. Hoses need to have a service pressure rating of 800 psig. Recovery cylinders need to have a 400 psig service GUIDE FOR R-410A • R-410A refrigerant operates at approximately 60% higher pressure (1.6 times) than R-22. Ensure that servicing INSTRUCTIONS. - Rheem RAMP-JEZ | Installation Instructions - Page 10

specifically designed for R-410A. LOCATION Do not install the indoor evaporator coil in the return duct system of a gas or oil furnace. Provide a service inlet to the coil for inspection and cleaning. Keep the coil pitched toward the drain connection. ! CAUTION When coil is installed over a finished - Rheem RAMP-JEZ | Installation Instructions - Page 11

kinking. • Route the tubing using temporary hangers, then straighten the tubing and install permanent hangers. Line must be adequately supported. • The vapor line must be insulated to prevent dripping (sweating) and prevent performance losses. Armaflex and Rubatex are satisfactory insulations - Rheem RAMP-JEZ | Installation Instructions - Page 12

braze any fitting with the TEV sensing bulb attached. • Braze the tubing between the outdoor unit and indoor coil. Flow dry nitrogen into a service port and through the tubing while brazing. • After brazing - use an appropriate heatsink material to cool the joint and remove any flux residue. • The - Rheem RAMP-JEZ | Installation Instructions - Page 13

TABLE 6 LIQUID LINE SIZE - OUTDOOR UNIT ABOVE INDOOR COIL Liquid Line Size Line Size System Connection Line Size Outdoor Unit Above Indoor Coil (Cooling Only - Does not apply to Heat Pumps) Capacity Size (Inch O.D.) Total (Inch I.D.) 25 50 75 100 125 150 Minimum Vertical Separation - - Rheem RAMP-JEZ | Installation Instructions - Page 14

the service panel and adjusted, if required. Allow a minimum of 5 minutes running. Before analyzing charge, see the instructions on the unit service panel . Excessive indoor airflow increases the possibility of high humidity problems. Low indoor airflow reduces total capacity, and causes coil icing. - Rheem RAMP-JEZ | Installation Instructions - Page 15

Liquid pressure method is used for charging systems in the cooling mode when an expansion valve is used on the evaporator. The service port on the liquid service valve (small valve) is used for this purpose. Read and record the outdoor ambient temperature entering the condensing unit, and the liquid - Rheem RAMP-JEZ | Installation Instructions - Page 16

interconnecting tubing and evaporator coil is adequate; otherwise, evacuate the entire system. Use the factory charge shown in Table 1 of these instructions or unit data plate. Note that charge value includes charge required for 15 ft. of standard size interconnecting liquid line. Calculate actual - Rheem RAMP-JEZ | Installation Instructions - Page 17

between thermostat and outdoor unit. CONTROL WIRING (See Figure 4) If the low voltage control wiring is run in conduit with the power supply, Class I insulation is required. Class II insulation is required if run separate. Low voltage wiring may be run through the insulated bushing provided in the - Rheem RAMP-JEZ | Installation Instructions - Page 18

the compressor from operating in pressure ranges which can cause damage to the compressor. Both controls are in the low voltage control cir-cuit. High pressure control (HPC) is a manual reset which opens near 610 PSIG. Do not reset arbitrarily without first determining what caused it to trip. The - Rheem RAMP-JEZ | Installation Instructions - Page 19

dimming. TIME DELAY CONTROL (TDC) The time delay (TDC) is in the low voltage control circuit. When the compressor shuts off due to a power failure or UNIT COVER BEFORE OPERATING OUTDOOR UNIT CAN CAUSE COMPONENTS TO FAIL. SERVICE SINGLE-POLE COMPRESSOR CONTACTOR (CC) Single-pole contactors are used - Rheem RAMP-JEZ | Installation Instructions - Page 20

TROUBLE SHOOTING In diagnosing common faults in the air conditioning system, it is useful to present the logical pattern of thought that is used by experienced technicians. The charts which follow are not intended to be an answer to all problems, but only to guide your thinking as you attempt to - Rheem RAMP-JEZ | Installation Instructions - Page 21

MECHANICAL CHECKS FLOW CHART Unit Running? High Head Pressure YES Pressure problems? Low Head Pressure Dirty Condenser Coil Low on Charge Inoperative Outdoor Fan Open IPR Valve Overcharge Low Ambient Temperature Recirculation of Condenser Air Inoperative Compressor Valves Non-condensibles - Rheem RAMP-JEZ | Installation Instructions - Page 22

TROUBLESHOOTING TIPS SYSTEM PROBLEM INDICATORS DISCHARGE PRESSURE SUCTION PRESSURE SUPERHEAT SUBCOOLING COMPRESSOR AMPS Overcharge High High Low High High Undercharge Low Low High Low Low Liquid Restriction (Drier) Low Low High High Low Low Evaporator Airflow Low Low Low - Rheem RAMP-JEZ | Installation Instructions - Page 23

TROUBLE SHOOTING CHART ! WARNING DISCONNECT ALL POWER TO UNIT BEFORE SERVICING. CONTACTOR MAY BREAK ONLY ONE SIDE. • Flowcheck piston size too large • Defective Compressor valves • Incorrect capillary tubes • Low indoor airflow • Operating below 65°F outdoors • Moisture in system • Excessive load • - Rheem RAMP-JEZ | Installation Instructions - Page 24

FIGURE 4 SINGLE-PHASE WIRING DIAGRAM 24 - Rheem RAMP-JEZ | Installation Instructions - Page 25

FIGURE 5 THREE-PHASE WIRING DIAGRAM (C, D & Y VOLTAGES) 25 - Rheem RAMP-JEZ | Installation Instructions - Page 26

FIGURE 6 26 - Rheem RAMP-JEZ | Installation Instructions - Page 27

27 - Rheem RAMP-JEZ | Installation Instructions - Page 28

28 CM 0908

92-21354-51-08

SUPERSEDES 92-21354-51-07

AIR-COOLED CONDENSING UNITS

(-)ANL-*AZ MODEL SERIES – 13 SEER

(-)APL-JAZ MODEL SERIES – 14 SEER

(-)APM-JAZ MODEL SERIES – 14.5 SEER

INSTALLATION INSTRUCTIONS

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORT

TION!

!

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE BY A SERVICEMAN

WARNING

!

ANT SAFETY

INFORMA

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR PROPER

INSTALLATION, ADJUSTMENT AND OPERATION OFTHIS

UNIT.READ THESE INSTRUCTIONS THOROUGHLY BEFORE

ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO

FOLLOWTHESE INSTRUCTIONS MAY RESULT IN IMPROPER

INSTALLATION, ADJUSTMENT,SERVICE OR MAINTENANCE

POSSIBLY RESULTING INFIRE,

ELECTRICAL SHOCK,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

[ ] INDICATES METRIC CONVERSIONS

efrigerant

ISO 9001:2000

(14.5 SEER MODELS

& 14 OR 13 SEER

MODELS IN CERTAIN

MARKED SYSTEMS)