Samsung WA476DSHASU/A1 Trouble Shooting Guide User Manual Ver.1.0 (English, Fr - Page 3

Warning

|

View all Samsung WA476DSHASU/A1 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

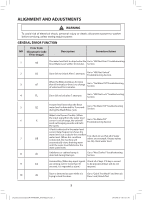

ALIGNMENT AND ADJUSTMENTS WARNING To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless testing requires power. Error Code NO (Diagnostic Code Error Image) Description Corrective Action 11 TE1 This occurs when the water temperature sensor fault is detected continuously for 5 seconds. Go to " Board Input Test" and check Water Temperature. Check loose or pinched wires. Replace PCB or thermistor. MICOM is attempting to drive the motor but is not getting any response signals Evaluate wire harness for loose or 12 3E from the hall sensor. Visual check shows unhooked connections. Go to " Quick motor is not running. (Locked, Defective Test Mode" and test Motor. Hall Sensor or Overload) 13 HE Heater Relay Failure (No Heater Relay Check Signal) Replace PCB 14 nF1 The hot/cold water hose connection is Please connect the hot/cold water not correct. hose connection correctly. 15 SUd Suds is detected during the washing session. ("SUdS" is not an error. When it finishes washing, End and the SUd Guide a user to reduce amount of detergent usage. code will blink in turn.) 16 AE Communication error between SUB Check Main PBA, SUB PBA & Wire- PBA and MAIN PBA harness. Replace PCB This error occurs when the position of the clutch is not detected. - If the position detection signal is not received 15 seconds after the clutch 1. Check the clutch motor. 17 PE motor starts, the spin drum is shaken 2. Check the assembly status of the (Clutch Motor Error) left and right and then the motor is clutch motor. restarted. 3. Check the wire connector terminals. If the motor position signal is not received even after 3 reattempts, a PE error occurs. After the completion of the clutch position detection, and the clutch hall signal is invalid, the spin drum is shaken left and right and then the 1. Check the clutch hall sensor. PE1 clutch hall signal is evaluated again. 2. Check the wire connector terminals. 18 (clutch hall sensor This, if the clutch hall signal is still 3. Check the clutch switching status. error) invalid, the clutch position switching - Check the coupling assembly and status is checked and then the disassembly status. operation is restarted. (If the 15 reattempts fail, this error occurs.) If the output from the MEMS sensor 19 8E is over 4.5V or under 0.5V and it continues for 5 seconds, this error 1. Check the MEMS sensor and PBA. 2. Check the wire connector terminals occurs. 3 [Technical information]WA484DSHA_03051B_EN.indd 3 2012-06-25 �� 11:11:58