Schwinn Tango Tandem Seven IPS Schwinn Owner's Manual - Page 43

rotor. If fingers contact brake while wheel is turning injury can occur.

|

View all Schwinn Tango Tandem Seven IPS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 43 highlights

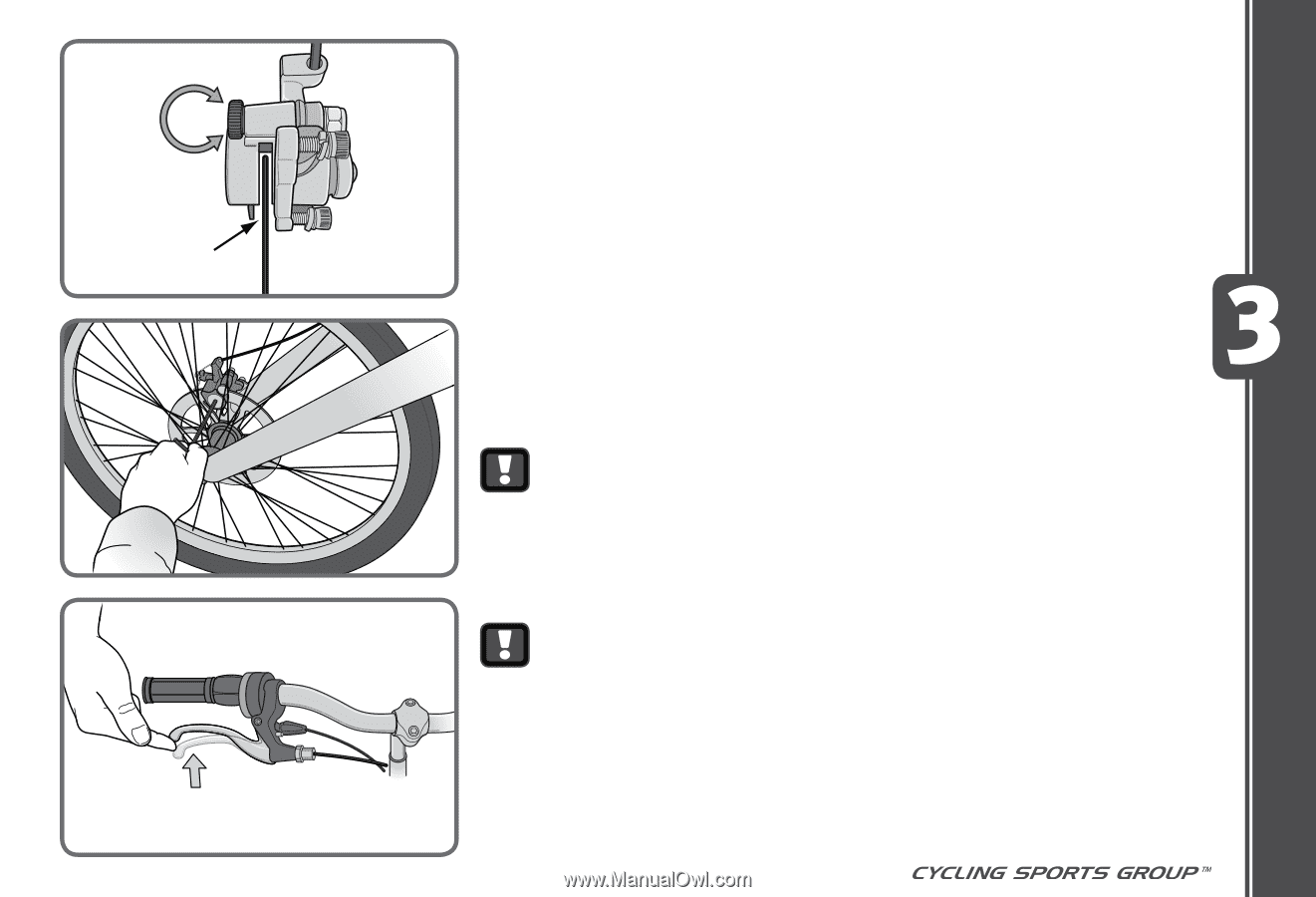

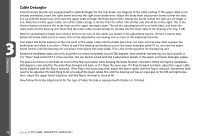

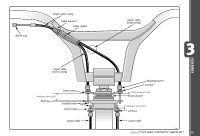

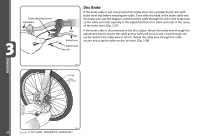

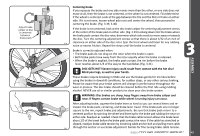

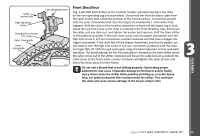

Adjust brake caliper so disc is centered between brake pads Centering brake If you squeeze the brake and one side moves more than the other, or one side does not move at all, then the brake is not centered, or the wheel is not centered. First determine if the wheel is centered. Look at the gap between the tire and the fork or frame on either side. If it is not even, loosen wheel axle nuts and center the wheel, then proceed to centering the brake. (Fig. 3.39, 3.40) If the brake is not centered, look at the disc brake caliper for centering adjustment screws at the center of the brake pad on either side. (Fig. 3.39) Looking down into the brake where the brake pads contact the disc rotor, determine which side needs to move away or towards the disc. Turn the centering adjustment screws so that there is about 1/32 of an inch of 3.39 clearance on either side of the disc rotor. Spin the front wheel and listen for any rubbing noise or excess friction. Repeat the steps until the brake is centered. Brake is correctly adjusted when: • The brake pads do not drag on the rotor when the brake is open. • Both brake pads move away from the rotor equally when the brake is released. • When the brake is applied, the brake pads contact the rim before the brake lever reaches about 1/3 of the way to the handlebar. (Fig. 3.41) DISC GETS HOT! Severe injury could result from contact with the hot disc! Mind your legs, as well as your hands. These brakes require breaking in! Ride and use the brakes gently for 13 miles before using the brakes in downhill conditions, for sudden stops, or any other serious braking. Please be aware that your brake system will change in performance throughout the 3.40 wear-in process. The disc brake should be cleaned before the first ride using rubbing alcohol. NEVER use oil or similar products to clean your disc brake system. WARNING: Disc brakes are sharp, keep fingers away from brake caliper and rotor. If fingers contact brake while wheel is turning injury can occur. After adjusting brake, squeeze the brake lever as hard as you can several times and reinspect the brake pads, centering, and brake lever travel. If the brake pads are no longer square to the rim, repeat brake pad adjustments. Be sure that brake pads return to a centered position by spinning the wheel and listening for the brake pad rubbing the rotor on either side. Readjust as needed. Check that the brake cable tension allows the brake lever about 1/3 of the travel before the brake pads contact the rotor. If the cable has stretched or slipped, readjust brake cable tension by loosening cable anchor bolt and pulling more cable 3.41 through the anchor or use brake adjustment barrels for fine tuning brake cable tension. ©2010 43 ASSEMBLY