Schwinn Tango Tandem Seven IPS Schwinn Owner's Manual - Page 52

Detailed Maintenance

|

View all Schwinn Tango Tandem Seven IPS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 52 highlights

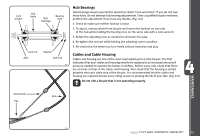

DETAILED MAINTENANCE How to fix a flat tire If you need to repair a tire, follow these steps: 1. Remove the wheel from the bicycle. 4.1 2. Deflate the tire completely via the valve. Loosen the tire bead by pushing it inward all the way around. (Fig. 4.1) 3. Press one side of the tire bead up over the edge of the rim. NOTE: Use tire levers, not a screwdriver, otherwise you may damage the rim. (A good substitute for tire levers are the handles of metal kitchen spoons, there are no sharp edges that may damage the tire or tube. (Fig. 4.2) ) 4. Remove the tube, leaving one tire bead on the rim. 5. Locate the leaks and patch using a tube repair kit, carefully following the repair kit instructions, or replace the tube. NOTE: Ensure that the replacement tube size matches the size stated on the tire sidewall and that the valve is the correct type for your bicycle. 4.2 6. Match the position of the leak in the tube with the tire to locate the possible cause and mark the location on the tire. 7. Remove the tire completely and inspect for a nail, glass, etc. and remove if located. Also inspect the inside of the rim to ensure there are no protruding spokes, rust or other potential causes. Replace the rim tape which covers the spoke ends, if damaged. 8. Remount one side of the tire onto the rim. 9. Using a hand pump, inflate the tube just enough to give it some shape. 10. Place the valve stem through the hole in the rim and work the tube into the tire. NOTE: Do not let it twist. 4.3 11. Using your hands only, remount the other side of the tire by pushing the edge toward the center of the rim. Start on either side of the valve and work around the rim. (Fig. 4.3) 12. Before the tire is completely mounted, push the valve up into the rim to make sure the tire can sit squarely in position. 13. Fit the rest of the tire, rolling the last, most difficult part on using your thumbs. NOTE: Avoid using tire levers as these can easily puncture the tube or damage the tire. 14. Check that the tube is not caught between the rim and the tire bead at any point. 15. Using a hand pump, inflate the tube until the tire begins to take shape, and check that the tire bead is evenly seated all the way around the rim. When properly seated, fully inflate the tire to the pressure marked on the sidewall. Use a tire air pressure gauge to check. 16. Replace the wheel into the frame checking that all gears, brakes, axle nuts or quick release levers are properly tightened. MAINTENANCE 52 ©2010