Schwinn Tango Tandem Seven IPS Schwinn Owner's Manual - Page 54

Brakes

|

View all Schwinn Tango Tandem Seven IPS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 54 highlights

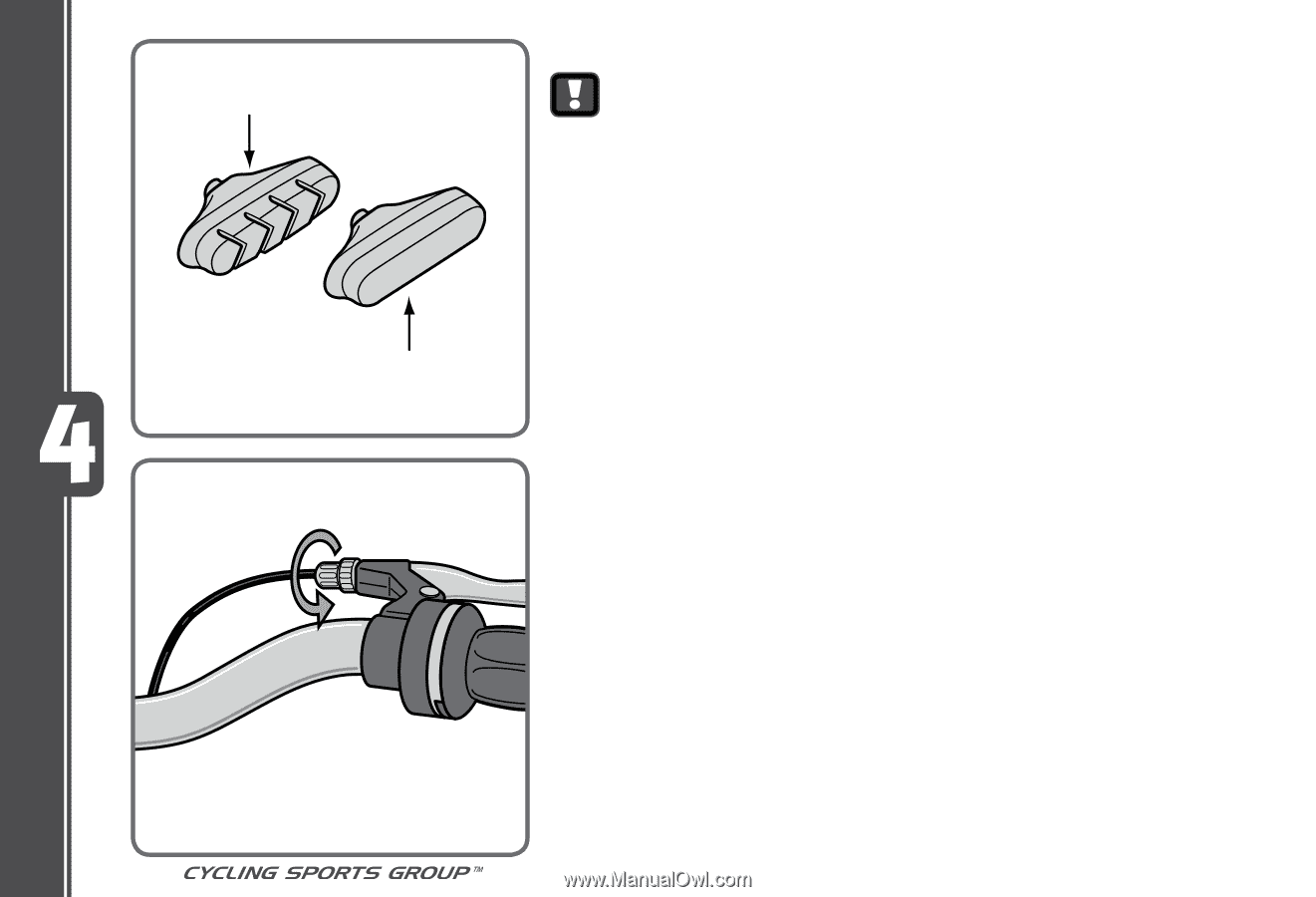

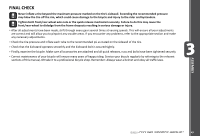

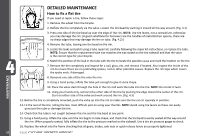

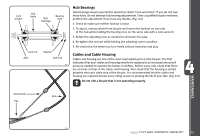

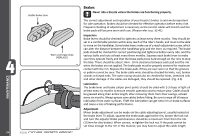

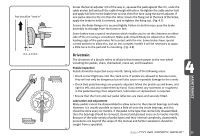

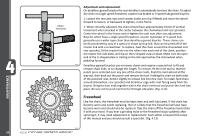

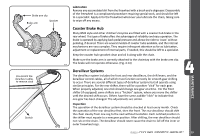

Usable brake shoe Brakes Never ride a bicycle unless the brakes are functioning properly. The correct adjustment and operation of your bicycle's brakes is extremely important for safe operation. Brakes should be checked for effective operation before every ride. Frequent checking of adjustment is necessary as the control cables will stretch and the brake pads will become worn with use. (Please refer to p. 32-41) Worn out brake shoe (REPLACE) 4.6 Inspection Brake levers should be checked for tightness at least every three months. They should be set in a comfortable position within easy reach of the rider's hands, and must not be able to move on the handlebar. Some brake levers make use of a reach adjustment screw, which can alter the distance between the handlebar grip and the lever, as required. The brake pads should be checked for correct positioning and tightness before every ride, and the various bolts and nuts at least every three months. Squeeze each brake lever to make sure they operate freely and that the brake pads press hard enough on the rims to stop the bike. There should be about 1mm - 2mm clearance between each pad and the rim when the brakes are not applied. The brake pads must be properly centered for maximum contact with the rim. Replace the brake pads if they are over worn so that the grooves or pattern cannot be seen. The brake cable wires should be checked for kinks, rust, broken strands or frayed ends. The outer casing should also be checked for kinks, stretched coils and other damage. If the cables are damaged, they should be replaced. (Fig. 4.6) MAINTENANCE Lubrication The brake lever and brake caliper pivot points should be oiled with 2-3 drops of light oil at least every six months to ensure smooth operation and to reduce wear. Cables should be greased along their entire length, after removing them from their casings, at least every six months. Always grease new cables before fitting. Be sure to wipe off all excess lubrication from outer surfaces. If left the lubrication can get onto rim or brake surfaces and cause a loss of braking performance. Adjustment Minor brake adjustment can be made via the cable adjusting barrel, usually located at the brake lever. To adjust, squeeze the brake pads against the rim, loosen the lock nut and turn the adjuster Brake pad clearance should be a maximum 2mm from the rim. (1/2mm for disc brakes) When correct, re-tighten the lock nut. If the pads cannot be set close enough to the rim in this manner, you may have to adjust the cable length. 4.7 54 ©2010