Sharp MX-M450N Operation Manual - Page 61

Loading paper in the bypass tray, width of the paper to be used.

|

View all Sharp MX-M450N manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 61 highlights

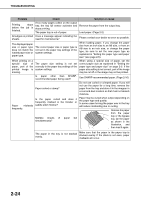

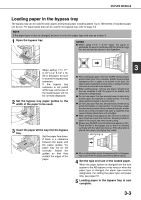

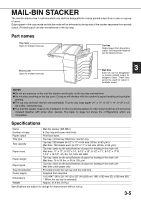

DUPLEX MODULE Loading paper in the bypass tray The bypass tray can be used for plain paper and special paper including labels. Up to 100 sheets of standard paper can be set. For paper types that can be used in the bypass tray, refer to page 2-3. NOTE If the paper type or size is changed, be sure to enter the paper type and size as in step 4. 1 Open the bypass tray. NOTES ● When using 5-1/2" x 8-1/2" paper, A5 paper or postcards, be sure to load them with their shorter edge into the feed slot as shown in the illustration. Bypass tray extension When setting 11"x 17", 8-1/2" x 14", 8-1/2" x 13, A3 or B4 paper, be sure to extend the bypass tray extension. If the bypass tray extension is not pulled all the way out the size of the loaded paper will not be correctly displayed. 2 Set the bypass tray paper guides to the width of the paper to be used. 3 Insert the paper all the way into the bypass tray. Set the paper face down. If there is a clearance between the paper and the paper guides, the paper may not be fed correctly. Adjust the guides so that they contact the edges of the paper. 3 ● When loading plain paper other than SHARP standard paper, special media other than postcards, SHARP-recommended transparency film, or paper to be printed on the back, the paper must be loaded one sheet at a time. Loading more than one sheet at a time will cause misfeeds. ● When adding paper, remove any paper remaining in the tray, combine it with the paper to be added, and reload as a single stack. ● Do not use paper that has already been printed on by a plain paper fax machine or a laser printer. This may cause printed images to become dirty. ● Do not use paper that has already been printed on by a thermal transfer or inkjet printer. In particular, paper that has been printed on by a thermal transfer printer (such as a word processor that uses a cassette) may cause missing characters and smudges. ● When printing on transparency film, be sure to remove each sheet as it exits the machine. Allowing sheets to stack in the output tray may cause curling. ● Please use SHARP-recommended transparency film. Place the film in the bypass tray so that it is oriented vertically with the label side face up. If the label side is placed face down, smudging may result. Label facing up ● When loading multiple sheets of transparency film in the bypass tray, be sure to fan the sheets several times before loading. 4 Set the type and size of the loaded paper. When the paper system is changed from the inch system to the AB system or vise versa or when the paper type is changed, the paper type must be designated. For setting the paper type and paper size, see page 2-5. 5 Loading paper in the bypass tray is now complete. 3-3