Sharp XL-UH250 Service Manual

Sharp XL-UH250 Manual

|

View all Sharp XL-UH250 manuals

Add to My Manuals

Save this manual to your list of manuals |

Sharp XL-UH250 manual content summary:

- Sharp XL-UH250 | Service Manual - Page 1

XL-UH250 SERVICE MANUAL No. S2709XLUH250/ MICRO COMPONENT SYSTEM USB VIDEO /AUX USB XL-UH250 MODEL XL-UH250 XL-UH250 Micro Component System consisting of XL-UH250 (main unit) and CP-UH250 (speaker system). • In the interests of user-safety (Required by safety regulations in some countries) - Sharp XL-UH250 | Service Manual - Page 2

XL-UH250 AXSMEPeRuLardE-vMrMkiiCocePAPet1U1M55T00aIOnuNaSl FOR USING LEAD-FREE SOLDER 1. Employing lead- solder. The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals.The alphabetical character following LF shows the type of lead-free solder. Example: Indicates - Sharp XL-UH250 | Service Manual - Page 3

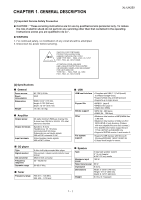

1. GENERAL DESCRIPTION XL-UH250 [1] Important Service Safety Precaution CAUTION : "These servicing instructions are for use by qualified service personnel only. To reduce the risk of electric shock do not perform any servicing other than that contained in the operating instructions unless you are - Sharp XL-UH250 | Service Manual - Page 4

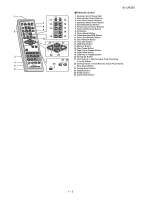

XL-UH250 [3] Names Of Parts XL-UH250 Front panel 1. Disc Trays 2. Timer Indicator 3. Remote Sensor 4. Disc or USB Stop Button 5. Disc or USB Play or Repeat Button 6. POWER ON/STAND-BY Button 7. - Sharp XL-UH250 | Service Manual - Page 5

XL-UH250 Remote control 1 1. Remote Control Transmitter 2. Disc Number Select Buttons 11 15 3. Disc Direct Search Buttons 7 12 4. Equalizer Mode Select Button 16 5. Extra Bass/Demo Button 2 8 - Sharp XL-UH250 | Service Manual - Page 6

XL-UH250 CHAPTER 2. ADJUSTMENTS [1] CD Section 1. CD SECTION • Adjustment Since this CD system incorporates the following automatic adjustment functions, readjustment is not needed when replacing the pickup. - Sharp XL-UH250 | Service Manual - Page 7

down the 3 button and 44 button. Then, press the CD button to enter the test mode.\ XL-UH250 Step 1 Step 2 Step 3 Step 4 Step 5 CD TE ST OPEN/CLOSE operation is using manual. > key input. Laser ON. > key input. Focus ON > key input. CLV Servo ON > key input. Tracking - Sharp XL-UH250 | Service Manual - Page 8

XL-UH250 STOP and return to Step 1 Everytime > key input a) Focus Balance = FB : XX b) Focus Gain = FG : XX c) Tracking Balance = TB : XX d) Tracking Gain = TG : XX e) - Sharp XL-UH250 | Service Manual - Page 9

Of Stereo System Error Message Display Contents XL-UH250 CD TUNER Error Contents DISPLAY CD Changer Mechanism pressing down the 3 button and the 4 button, press the number will be displayed as "XL H****" and " FW****V**". 3. Press the 4 button until "WAIT"--> "FINISHED" appears. 4. - Sharp XL-UH250 | Service Manual - Page 10

XL-UH250 [4] CD Changer Mechanism Section • All numbers in the drawing correspond to those in parts guide (CHANGER MECHANISM PARTS). 1 141 140 HALF GEAR MUST BE ARRANGED AS SHOWN 2 - 5 - Sharp XL-UH250 | Service Manual - Page 11

2 139 APPLY SANKOL SHS1001 BEFORE FIX XL-UH250 FIX ITEM 139 ACCORDING TO THE PICTURE AS SHOWN ABOVE ROTATE MODE BIG GEAR UNTIL REACH AS SHOWN IN PICTURE 2 - 6 - Sharp XL-UH250 | Service Manual - Page 12

XL-UH250 3 143 APPLY GREASE SC141 112 PULL THE LEVER UNITIL REACH THE ARROW MARK 2 - 7 - Sharp XL-UH250 | Service Manual - Page 13

XL-UH250 4 FIGURE 1 152 118 FIGURE 2 142 APPLY GREASE SC141 SLOT CLAMP SWITCH ARM INSIDE BASE SLOT HALF GEAR MUST BE ARRANGED AS SHOWN 2 - 8 - Sharp XL-UH250 | Service Manual - Page 14

XL-UH250 5 APPLY GREASE SC141 AT BOTTOM SIDE OF GEAR FOLLOW MARKING (REFER TO GRAY AREA) NO NEED TO APPLY GREASE AT BOTTOM SIDE CORRECT FIGURE 1 BLACK - Sharp XL-UH250 | Service Manual - Page 15

XL-UH250 6 APPLY GREASE SC141 AT HALF GEAR AREA ROTATE CLOCKWISE UNTIL REACH HERE (MAXIMUM) 129 2 - 10 - Sharp XL-UH250 | Service Manual - Page 16

XL-UH250 7 149 150 151 2 - 11 - Sharp XL-UH250 | Service Manual - Page 17

XL-UH250 8 THE SHOWN AREA MUST FREE FROM GREASE GREASE SC141 APPLICATION LENGTH GREASE APPLICATION PORTION CORRECT INCORRECT 124 131 SHOWN HOLE MUST FACING ARROW DIRECTION 2 - 12 - Sharp XL-UH250 | Service Manual - Page 18

XL-UH250 9 138 126 125 TR-RE JOINT GEAR C APPLY GREASE SC141 AT BOTTOM SIDE ONLY APPLY GREASE SC141 ONLY AT TOP SIDE GEAR MUST BE FIXED ACCORDINGLY TO THE HOLE'S 2 - 13 - Sharp XL-UH250 | Service Manual - Page 19

XL-UH250 10 148 147 146 145 2 - 14 - Sharp XL-UH250 | Service Manual - Page 20

XL-UH250 11 121 APPLY GREASE SC141 144 130 WHEN FIXING ITEM 144 MUST FOLLOW AS SHOWN 2 - 15 - Sharp XL-UH250 | Service Manual - Page 21

12 117 FIGURE 1 XL-UH250 FIGURE 2 APPLY GREASE SC141 FIGURE 3 APPLY GREASE SC141 2 - 16 - Sharp XL-UH250 | Service Manual - Page 22

XL-UH250 13 ITEM 133 , 134 MUST APPLY GREASE SC141 ON TOP SIDE GEAR ONLY 134 GEAR 112 133 CORRECT GEAR 112 INCORRECT 132 TOP VIEW AFTER BEING ASSEMBLED IT IS INCORRECT TO FIX IT IN REVERSED DIRECTION 2 - 17 - Sharp XL-UH250 | Service Manual - Page 23

14 APPLY GREASE SC141 BEFORE FIX MOVE 112 UNTIL TOUCH THE WALL XL-UH250 B A DURING GEAR A ROTATE MUST PRESS SHOWN AREA AND LEVER B WILL MOVE ARROW DIRECTION THEN FIX PART 108 108 803 x6 SCREW TORQUE 2 +0.5 - 0 kgf-cm APPLY GREASE SC141 CONFIRM WHETHER FIXED PROPELY OR NOT 2 - 18 - Sharp XL-UH250 | Service Manual - Page 24

XL-UH250 15 APPLY GREASE SC141 113 BEHIND THE LEVER NEED TO APPLY GREASE SC141 PULL IT THEN LEVER WILL MOVE IN 2 - 19 - Sharp XL-UH250 | Service Manual - Page 25

16 XL-UH250 123 115 APPLY GREASE SC141 APPLY GREASE SC141 AT BOSS APPLY GREASE SC141 BEFORE FIX SPRING MUST BE ARRANGED UNDER THE HOOK LR JOINT LEV BOARD R BOARD R LR JOINT LEV 2 - 20 - Sharp XL-UH250 | Service Manual - Page 26

XL-UH250 17 IT IS INCORRECT IF ASSEMBLED IN A REVERSED DIRECTION 103 137 136 APPLY GREASE SC141 BIG SLOT MUST FACING OUT WHEN FIX AND AFTER FIXED TO BASE CHASSIS. AFTER ASSEMBLY, CONFIRM WITH FREE DROP TEST GEAR POSITION DURING FIXING 2 - 21 - Sharp XL-UH250 | Service Manual - Page 27

18 XL-UH250 IT IS INCORRECT IF ASSEMBLED IN A REVERSED DIRECTION APPLY GREASE SC141 104 135 136 BIG SLOT MUST FACING OUT WHEN FIX AND AFTER FIXED TO BASE CHASSIS AFTER ASSEMBLY, CONFIRM WITH FREE DROP TEST GEAR POSITION DURING FIXING CONFIRM BOTH GEARS SIT PROPERLY AND LOCKED 2 - 22 - Sharp XL-UH250 | Service Manual - Page 28

XL-UH250 19 AFTER FIX OUTER UP/DOWN LEVER HOLD AS SHOWN PORTION AND MOVE UP/DOWN THEN CONFIRM WHETHER LEVER GO INSIDE THE HOLE OR NOT - Sharp XL-UH250 | Service Manual - Page 29

XL-UH250 20 BIG SLOT FACING OUT 110 2 - 24 - Sharp XL-UH250 | Service Manual - Page 30

XL-UH250 21 PUSH THE LEVER ACCORDING TO ARROW DIRECTION THEN FIX WHEN FIXING MAIN BASE ASSEMBLY FOLLOW ACCORDING TO PICTURE 1 PICTURE 1 PICTURE 3 PICTURE 2 CORRECT INCORRECT INCORRECT MAKE SURE MECHA HOLDER SHAFT FIX PROPERLY TO LEVER 2 - 25 - Sharp XL-UH250 | Service Manual - Page 31

UH250 22 APPLY SANKOL (SHS1001) APPLY SANKOL (SHS1001) ON TOP APPLY SANKOL (SHS1001) INSIDE 101 THE SLOT & OTHER SHOWN PORTION 102 APPLY SANKOL (SHS1001) APPLY SANKOL (SHS1001) AT BACK PORTION APPLY SANKOL (SHS1001) AT TRAY SLIDING PORTION FIX TRAY NO 1 FIRST THAN FOLLOW OTHER COSMO GUIDE - Sharp XL-UH250 | Service Manual - Page 32

XL-UH250 23 111 GEAR UP/DOWN BOARD APPLY GREASE SC141 AT INNER & OUTER GEAR SLIDING PORTION WHEN FIX GEAR UP/ DOWN BOARD THE TWO LEVER MUST AT PARALLEL LINE AND POSITIONED AT TOP MAX SIDE AFTER ASSEMBLY GEAR UP/DOWN BOARD 2 - 27 - Sharp XL-UH250 | Service Manual - Page 33

24 XL-UH250 SCREW TORQUE 3 +0.5 - 0 kgf-cm 804 ROTATE THE GEAR TO MOVE UP 111 GEAR UP AND DOWN BOARD BEFORE SCREW 2 - 28 - Sharp XL-UH250 | Service Manual - Page 34

XL-UH250 25 AFTER ASSEMBLY TOP PLATE FIX THE FFC FFC4 AFTER PUSH, MAKE SURE SNAP PROPERLY BACK PORTION 122 AFTER FIX, PUSH FOLLOW ARROW DIRECTION PRESS IN 107 BEFORE LOCK SLOT IN AFTER LOCK BEFORE LOCK AFTER LOCK MUST CONFIRM BEFORE LOCK AFTER LOCK MUST CONFIRM 2 - 29 - Sharp XL-UH250 | Service Manual - Page 35

26 XL-UH250 CORRECT CAUTION 1. MAKE SURE NO PWB CHIP INSIDE SET .( BEFORE FIX MAKE SURE PWB IS FREE FROM DUST , GREASE & ETC ) INCORRECT 803 2 - 30 - Sharp XL-UH250 | Service Manual - Page 36

XL-UH250 27 APPLY GREASE SC141 THE TWO SLOT MUST FREE FROM GREASE SC141 APPLY GREASE SC141 ASSEMBLY SEQUENCE BELOW THE MARKING 1. APPLY GREASE SC141 TO MAIN - Sharp XL-UH250 | Service Manual - Page 37

XL-UH250 28 13.8 + 0.2 -0 12.2 -+ 0.1 REFERENCE ONLY MOTOR GEAR HEIGHT FROM MAIN BASE 12.2 +- 0.1 MOTOR SCREWING HOLE MUST HAVE GAP M1,2 SCREW TORQUE 1.5 + 0.5 -0 AFTER SCREW MOTOR, CONFIRM THE ARRANGEMENT AS IN FIGURE 2 FIGURE 2 APPLY GREASE SC141 801 2 - 32 - Sharp XL-UH250 | Service Manual - Page 38

XL-UH250 29 APPLY SANKOL (SHS1001) 3.1 + 0.1 SHAFT X 3 DIM AFTER INSERTION MUST CONFIRM EVERYDAY SANKOL (SHS1001) APPLICATION AREA 109-2 APPLY GREASE AT THE SLIDING PORTION 114 116 APPLY GREASE SC141 2 - 33 - Sharp XL-UH250 | Service Manual - Page 39

30 AFTER ASSEMBLED TO HOLDER, STABILIZER NEED TO BE CLEANED WITH ALCOHOL DISC TOUCHING SURFACE XL-UH250 BOTTOM AREA OF STABILIZER 106 APPLY GREASE SC141 MUST MAKE SURE SNAP PROPERLY BOTH SIDE ALL SURFACE MUST TOUCH GAP INCORRECT CORRECT INCORRECT 2 - 34 - Sharp XL-UH250 | Service Manual - Page 40

XL-UH250 31 NO GAP CORRECT HAVE GAP INCORRECT 2 - 35 - Sharp XL-UH250 | Service Manual - Page 41

to eject the disc tray so that CD can be removed from the tray. Reduction gear D Up Down Figure 3 CD Disc Disc Tray Guide Tray Gear up down board XL-UH250 CD at play position. CD Disc CD at stalk position. Figure 1 Reduction gear C Mark 1 Mark 3 Mark 5 (DISC 1) (DISC 3) (DISC 5) Mark 2 Mark - Sharp XL-UH250 | Service Manual - Page 42

XL-UH250 [2] Disassembly Caution on disassembly Follow the below-mentioned notes when disassembling nylon bands or wire holders where they need to be removed when disassembling the unit. After servicing the unit, be sure to rearrange the leads where they were before disassembling. 4) Take - Sharp XL-UH250 | Service Manual - Page 43

Rear Panel (H1)x2 Ø3x10mm CD Mechanism (P2)x4 Special XL-UH250 Speaker PWB Figure 4 Display PWB Front Panel (J2)x1 CD Changer Unit (J4)x6 Ø2.6x10mm SUB PWB USB PWB (K1)x2 Ø2.6x10mm Jack PWB (L1) - Sharp XL-UH250 | Service Manual - Page 44

XL-UH250 CHAPTER 4. BLOCK DIAGRAM A B C D E F G H 1 2 3 4 5 6 Figure 1: MAIN BLOCK DIAGRAM (1/2) 4 - 1 - Sharp XL-UH250 | Service Manual - Page 45

XL-UH250 7 8 9 10 11 12 Figure 2: MAIN BLOCK DIAGRAM (2/2) 4 - 2 - Sharp XL-UH250 | Service Manual - Page 46

XL-UH250 A B C D E F G H 1 2 3 4 5 6 Figure 3: CD BLOCK DIAGRAM (1/2) 4 - 3 - Sharp XL-UH250 | Service Manual - Page 47

XL-UH250 7 8 9 10 11 12 Figure 4: CD BLOCK DIAGRAM (2/2) 4 - 4 - Sharp XL-UH250 | Service Manual - Page 48

XL-UH250 CHAPTER 5. CIRCUIT DESCRIPTION [1] Waveforms Of Servo Circuit 1 IC1 9 FOO 2 TRO IC1 10 1 IC1 9 FOO 6 IC1 13 DMO 1 FOO IC1 9 6 IC1 13 DMO 4 TEI IC1 6 1 FOO - Sharp XL-UH250 | Service Manual - Page 49

12 IC3 88 13 IC3 87 14 IC3 89 15 IC1 1 RXD1 TXD1 USB_REQ RESET 18 IC3 71 AIN 19 IC3 92 BCKI 20 IC3 93 LRCKI 16 IC3 80 D - 17 D + IC3 79 XL-UH250 5 - 2 - Sharp XL-UH250 | Service Manual - Page 50

XL-UH250 [2] IC Voltage IC701 PIN VOLTAGE PIN VOLTAGE 1 3.2 51 3.3 2 3.3 52 0.0 3 0.0 53 0.0 4 0.0 54 3.3 5 0.0 55 3.1 6 1.6 56 0.0 7 0.0 57 0.0 8 0.0 58 0.0 9 0.0 59 0.0 10 1.1 60 0.0 11 0.5 61 3.3 12 3.1 62 3.3 13 1.5 63 0.0 14 0.0 - Sharp XL-UH250 | Service Manual - Page 51

1.6 12 1.6 13 1.6 14 1.6 15 1.6 16 1.6 17 1.6 18 1.6 19 3.2 20 3.2 21 0.0 22 0.0 23 0.0 24 0.0 25 0.0 26 7.0 27 7.1 28 7.1 29 0.0 30 1.6 31 2.2 32 3.2 33 3.2 34 2.7 35 3.2 36 3.2 XL-UH250 5 - 4 - Sharp XL-UH250 | Service Manual - Page 52

XL-UH250 Q704 PIN VOLTAGE E 0.0 C 3.3 B 0.0 Q841 PIN VOLTAGE E 0.0 C 0.0 B 0.8 Q906 PIN VOLTAGE E 0.7 C 3.7 B 0.0 Q610 PIN VOLTAGE E 0.0 C 0.0 B 0.0 Q604 PIN VOLTAGE E 0.0 C 0.0 B 0.7 Q608 PIN VOLTAGE E 1.9 C 1.9 B 0.0 Q611 PIN VOLTAGE E 0.0 C - Sharp XL-UH250 | Service Manual - Page 53

XL-UH250 CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS LAYOUT [1] Notes On Schematic Diagram • Resistor: To differentiate the units of resistors, such symbol as K and M are used: the symbol K - Sharp XL-UH250 | Service Manual - Page 54

XL-UH250 [3] Schematic Diagram FM SIGNAL CD SIGNAL AUDIO SIGNAL A B C D E F G H 1 2 3 4 5 6 Figure 6-1: MAIN SCHEMATIC DIAGRAM (1/2) 6 - 2 - Sharp XL-UH250 | Service Manual - Page 55

XL-UH250 7 8 9 10 11 12 Figure 6-2: MAIN SCHEMATIC DIAGRAM (2/2) 6 - 3 - Sharp XL-UH250 | Service Manual - Page 56

XL-UH250 FM SIGNAL A B C D E F G H 1 2 3 4 5 6 Figure 6-3: POWER SCHEMATIC DIAGRAM (1/2) 6 - 4 - Sharp XL-UH250 | Service Manual - Page 57

XL-UH250 7 8 9 10 11 12 Figure 6-4: POWER SCHEMATIC DIAGRAM (2/2) 6 - 5 - Sharp XL-UH250 | Service Manual - Page 58

XL-UH250 A B C D E F G H 1 2 3 4 5 6 Figure 6-5: DISPLAY SCHEMATIC DIAGRAM (1/2) 6 - 6 - Sharp XL-UH250 | Service Manual - Page 59

XL-UH250 7 8 9 10 11 12 Figure 6-6: DISPLAY SCHEMATIC DIAGRAM (2/2) 6 - 7 - Sharp XL-UH250 | Service Manual - Page 60

XL-UH250 CD SIGNAL A B C D E F G H 1 2 3 4 5 6 Figure 6-7: CD MP3 SCHEMATIC DIAGRAM (1/2) 6 - 8 - Sharp XL-UH250 | Service Manual - Page 61

XL-UH250 7 8 9 10 11 12 Figure 6-8: CD MP3 SCHEMATIC DIAGRAM (2/2) 6 - 9 - Sharp XL-UH250 | Service Manual - Page 62

XL-UH250 [4] Charts Of Connecting Wires CNS971 TUNER PACK FFC301 A ANTENNA BR BK FM GND AM FFC301 B CNS601 9 8 7 6 5 4 3 2 1 1 11 GY BK GY BK GY BK GY BK - Sharp XL-UH250 | Service Manual - Page 63

XL-UH250 FFC4 FFC705 1 2 3 4 CNS706 RD YL WH BK GY USB PWB-B2 BK WH YL RD 54321 BI706 JK702 WH LUG3 FROM DISPLAY PWB-B1 CNP702 - Sharp XL-UH250 | Service Manual - Page 64

XL-UH250 [5] Wiring Side Of PWB SPEAKER PWB-A3 A SO901 SPEAKER TERMINAL B R-CH L-CH MAIN PWB-A1 L-CH in the MAIN, SPEAKER PWB. H Refer to "Precautions for handling lead-free solder" for instructions and precautions. 1 2 3 4 5 6 Figure 6-11: WIRING SIDE OF MAIN PWB (TOP VIEW) (1/2) 6 - Sharp XL-UH250 | Service Manual - Page 65

2 4 6 8 10 1 3 5 7 9 11 XL-UH250 RE-FLASH PWB-A4 BIU1 65432 1 CNPU3 6 5 4 32 1 CNPU1 87654321 CNPU2 8765432 1 VIDEO/AUX IN L-CH and R-CH ECB 12 5 4 3 21 SUBWOOFER PRE-OUT 7 8 9 10 11 12 Figure 6-12: WIRING SIDE OF MAIN PWB (TOP VIEW) (2/2) 6 - 13 - Sharp XL-UH250 | Service Manual - Page 66

XL-UH250 RE-FLASH PWB-A4 A B MAIN PWB-A1 C D E F G Lead-free solder indication H Lead-free solder is used in the MAIN, RE-FLASH PWB. Refer to "Precautions for handling lead-free solder" for instructions and precautions. 1 2 3 4 5 6 Figure 6-13: WIRING SIDE OF MAIN PWB (BOTTOM VIEW) - Sharp XL-UH250 | Service Manual - Page 67

XL-UH250 7 8 9 10 11 12 Figure 6-14: WIRING SIDE OF MAIN PWB (BOTTOM VIEW) (2/2) 6 - 15 - Sharp XL-UH250 | Service Manual - Page 68

XL-UH250 POWER PWB-A2 A 5 4 B 6 3 7 8 2 9 1 C 7 654321 WHITE BLACK indication Lead-free solder is used in the POWER PWB. H Refer to "Precautions for handling lead-free solder" for instructions and precautions. 1 2 3 4 Figure 6-15: WIRING SIDE OF POWER PWB 6 - 16 COLOR TABLE W - Sharp XL-UH250 | Service Manual - Page 69

-MEMO- XL-UH250 6 - 17 - Sharp XL-UH250 | Service Manual - Page 70

XL-UH250 A DISPLAY PWB-B1 RP753 5150 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 - Sharp XL-UH250 | Service Manual - Page 71

XL-UH250 FL701 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 -free solder is used in the DISPLAY PWB. Refer to "Precautions for handling lead-free solder" for instructions and precautions. 7 8 9 10 11 12 Figure 6-17: WIRING SIDE OF DISPLAY PWB (TOP VIEW) (2/2) 6 - 19 - Sharp XL-UH250 | Service Manual - Page 72

XL-UH250 A DISPLAY PWB-B1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 indication H Lead-free solder is used in the DISPLAY PWB. Refer to "Precautions for handling lead-free solder" for instructions and precautions. 1 2 3 4 5 6 Figure 6-18: WIRING SIDE OF DISPLAY PWB (BOTTOM VIEW) (1/2) - Sharp XL-UH250 | Service Manual - Page 73

C705 RP757 RD01 C740 R794 R793 R785 R786 R787 R788 RP776 R764 R792 R798 RP774 RD04 RD05 R773 R774 R775 R776 R777 R778 R779 R780 XL-UH250 D701 RP775 D702 C704 7 8 9 10 11 12 Figure 6-19: WIRING SIDE OF DISPLAY PWB (BOTTOM VIEW) (2/2) 6 - 21 - Sharp XL-UH250 | Service Manual - Page 74

XL-UH250 USB PWB-B2 A BI706 4 3 21 SUB PWB-B5 C722 LUG2-3 B LUG3 4 321 WH BK C FROM EXTERNAL USB, JACK, LED, SUB PWB. H Refer to "Precautions for handling lead-free solder" for instructions and precautions. 1 2 3 4 5 6 Figure 6-20: WIRING SIDE OF USB, JACK, LED, SUB PWB (TOP VIEW) - Sharp XL-UH250 | Service Manual - Page 75

XL-UH250 USB PWB-B2 A C748 C751 C746 D711 D710 B FB701 FB702 C FB703 FB705 SUB PWB-B5 D in the USB, JACK, LED, SUB PWB. H Refer to "Precautions for handling lead-free solder" for instructions and precautions. 1 2 3 4 5 6 Figure 6-21: WIRING SIDE OF USB, JACK, LED, SUB PWB (BOTTOM VIEW) - Sharp XL-UH250 | Service Manual - Page 76

XL-UH250 A CD MP3 PWB-C B C D M2 MAIN CAM MOTOR E + FFC4 11 1 M1 TRAY MOTOR - + 11 9 7 5 3 1 10 8 6 4 2 CNB1 1 11 CNP4 2 4 6 8 10 1 3 5 7 9 11 R44 R43 R42 R41 C65 CNP3 - Sharp XL-UH250 | Service Manual - Page 77

XL-UH250 C75 R26 R27 R28 R29 R30 R31 R32 R33 R36 RA29 RA30 RA31 RA32 R64 R65 C93 L2 the CD MP3, CD CHANGER PWB. Refer to "Precautions for handling lead-free solder" for instructions and precautions. 7 8 9 10 11 12 Figure 6-23: WIRING SIDE OF CD MP3 AND CD CHANGER PWB (TOP VIEW) (2/2) 6 - - Sharp XL-UH250 | Service Manual - Page 78

XL-UH250 A CD MP3 PWB-C JP5 L4 L3 R67 R58 C73 Q7 Q6 B C71 C74 R55 R99 RA1 R98 solder is used in the CD MP3 PWB. H Refer to "Precautions for handling lead-free solder" for instructions and precautions. 1 2 3 4 5 6 Figure 6-24: WIRING SIDE OF CD MP3 PWB (BOTTOM VIEW) (1/2) 6 - 26 - Sharp XL-UH250 | Service Manual - Page 79

XL-UH250 R47 Q5 C72 R56 71 55 D1 Q4 R50 R45 R93 R46 R92 R51 R40 C66 R48 Q8 C46 C45 R25 R24 C43 C44 R54 - Sharp XL-UH250 | Service Manual - Page 80

XL-UH250 CHAPTER 7. FLOWCHART [1] Troubleshooting 1. When the CD does not function The CD section after the above step is taken, check the following items. Remove the cabinet and follow the troubleshooting instructions. "Track skipping and/or no TOC (Table Of Contents) may be caused by build up - Sharp XL-UH250 | Service Manual - Page 81

. 3) Others. (1) Focus-RF system check. Although a CD is inserted and the cover is closed, "NO DISC" is displayed. 1. Does the pickup move? XL-UH250 Press the Tray1 CD Eject Button without inserting a disc, and try starting the playback operation. 1 FDO IC1 9 2 10 TRO IC1 Figure 1 No Sled - Sharp XL-UH250 | Service Manual - Page 82

XL-UH250 (2) Tracking system check. Check the TE waveform at pin 6 on IC1. If the waveform shown in Figure 4 appears and soon after NO DISC appears ? No " - Sharp XL-UH250 | Service Manual - Page 83

. (Figure 6) Check around Pins 72, 73, 74, 75, 76 and 78 on IC1. 7 IC1 74 8 76 IC1 6 13 IC1 1 9 IC1 TMAX LPFO DMO FDO Figure 6 XL-UH250 (5) Others. The RF waveform is normal and the time is displayed normally, but no sound is produced. Or the sound has dropouts. Is pin 65 - Sharp XL-UH250 | Service Manual - Page 84

XL-UH250 (6) USB system check. Press USB funnction, insert the USB memory device into the USB. 1. Does the device information can display? Yes 2. The waveform and the - Sharp XL-UH250 | Service Manual - Page 85

CHAPTER 8. OTHER XL-UH250 [1] Function Table Of IC IC2 VHILA6261//-1: Focus/Tracking/Spin/Sled Driver (LA6261) Pin No. 1 2 3 4 5 6 7 8 9 10 11 12* 13 14* 15 16* 17 18* 19 20 - Sharp XL-UH250 | Service Manual - Page 86

+ - + - + - + + - + + - XL-UH250 IC2 VHILA6261//-1: Focus/Tracking/Spin/Sled Driver (LA6261) 1 CH3 2 3 4 5 CH2 6 7 8 9 CH1 Pre Drive Pre Drive + - 36 CH4 35 + - 34 33 32 CH5 31 30 29 - Sharp XL-UH250 | Service Manual - Page 87

IC1 VHITC94A70FG5: CD MP3 DECODER (1/4) Pin Description XL-UH250 Figure 8-2 BLOCK DIAGRAM OF IC 8 - 3 - Sharp XL-UH250 | Service Manual - Page 88

XL-UH250 IC1 VHITC94A70FG5: CD MP3 DECODER (2/4) Pin Description Pin No. Symbol Input / Output Description 1 AVSS3 - Grounding pin for 3.3V CD analog circuits. 2 RFZi Input 3AI/F Input - Sharp XL-UH250 | Service Manual - Page 89

resistor for reference current generation. Reference voltage output pin for LD APC. LPF connection pin for RFEQO offset correction circuit. 8 - 5 XL-UH250 Default Remarks Input Schmitt input CMOS PORT Input Schmitt input CMOS PORT Input Output Output Output Output Output Input Schmitt input - Sharp XL-UH250 | Service Manual - Page 90

XL-UH250 IC1 VHITC94A70FG5: conditions: • /RST pin = Low • Crystal oscillation stopped according to the instructions by the Stop crystal oscillation command. • Power supply for CD is OFF. should be taken, such as using a driver IC supporting a standby feature to place the system in standby mode while either - Sharp XL-UH250 | Service Manual - Page 91

data bus Internal control bus Mode setting pins Mode control ROM controller / Interleave control Control Address Data Flash memory XL-UH250 Control circuit (including automatic sequence control circuit) Command register Address latch Data latch Column decoder / Sense amp Flash memory - Sharp XL-UH250 | Service Manual - Page 92

XL-UH250 IC851 VHIAN80T53/-1: MULTI REGULATOR (AN80T53) Pin Terminal Name Function No. 1 REG4 Output 5.1 V power supply with a minimum peak out current of 1200 mA. 2 REG3 Output 13 V - Sharp XL-UH250 | Service Manual - Page 93

[2] FL Display FL701 VVKNA12MM54-1 XL-UH250 GRID ASSIGNMENT 1G 12G 1a 2a 1a 2a 1a 2a 1a 2a 1a 2a MP3 WMA 1a 1a 1a 2a 2a 1a col2 Dot2 2a - Sharp XL-UH250 | Service Manual - Page 94

XL-UH250 -MEMO- 8 - 10 - Sharp XL-UH250 | Service Manual - Page 95

XL-UH250 PARTS GUIDE MICRO COMPONENT SYSTEM MODEL XL-UH250 XL-UH250 Micro Component System consisting of XL-UH250 (main unit) and CP-UH250 safety and performance of the set. SHARP CORPORATION This document has been published to be used for after sales service only. The contents are subject to - Sharp XL-UH250 | Service Manual - Page 96

XL-UH250 NO. PARTS CODE [1] INTEGRATED CIRCUITS IC1 IC2 IC3 IC5 IC601 IC701 IC702 IC703 IC705 IC851 IC852 IC853 IC854 IC901 VHITC94A70FG5 VHILA6261//-1 RH-IXA123AW00 VHI6201P332-1 VHIR2S15904-1 - Sharp XL-UH250 | Service Manual - Page 97

0.047 µF,50V 0.047 µF,50V 0.1 µF,16V 220pF(CH),50V 0.1 µF,16V 0.1 µF,16V 15pF(CH),50V 15pF(CH),50V 0.1 µF,16V 100 µF,10V,Electrolytic 0.1 µF,16V 22 µF,16V,Electrolytic 2 DESCRIPTION XL-UH250 - Sharp XL-UH250 | Service Manual - Page 98

XL-UH250 NO. PARTS CODE [7] CAPACITORS C43 C44 C45 C46 C48 C49 C50 C51 C52 C53 C54 C55 C56 C57 C58 C59 C60 C61 C62 C63 C64 - Sharp XL-UH250 | Service Manual - Page 99

,Electrolytic AA 0.01 µF,50V AN 3300 µF,71V,Electrolytic AH 4700 µF,35V,Electrolytic AH 4700 µF,35V,Electrolytic AN 3300 µF,71V,Electrolytic AB 47 µF,50V,Electrolytic 4 DESCRIPTION XL-UH250 - Sharp XL-UH250 | Service Manual - Page 100

XL-UH250 NO. PARTS CODE [7] CAPACITORS C928 C929 C931 C946 C960 C962 CA1 CA2 CA3 CA5 CP740 CP741 VCFYFA1HA104J VCFYFA1HA104J VCEAZA1HW106M VCEAZA1HW104M VCEAZA1HW335M VCKYCY1CB104K VCEAZA1AW227M VCCCCY1HH101J VCCCCY1HH101J - Sharp XL-UH250 | Service Manual - Page 101

AA 220 ohms,1/6W AA 470 ohms,1/16W AA 470 ohms,1/6W AA 1 kohms,1/16W AA 1 kohms,1/6W AA 47 kohms,1/6W AA 1 kohms,1/6W 6 XL-UH250 - Sharp XL-UH250 | Service Manual - Page 102

XL-UH250 NO. PARTS CODE [8] RESISTORS R752 VRS-CY1JB102J R753 VRS-CY1JB102J R754 VRS-CY1JB102J R755 VRS-CY1JB102J R756 VRS-CY1JB102J R757 VRS-CY1JB102J R758 VRS-CY1JB102J - Sharp XL-UH250 | Service Manual - Page 103

kohms,1/16W AA 10 kohms,1/16W AA 10 kohms,1/6W AA 2.7 kohms,1/16W AA 0 ohms,Jumper,0.8x1.55mm,Green AA 0 ohms,Jumper,0.8x1.55mm,Green 8 XL-UH250 - Sharp XL-UH250 | Service Manual - Page 104

XL-UH250 NO. PARTS CODE PRICE NEW PART RANK MARK RANK DESCRIPTION [9] OTHER CIRCUITRY PARTS BI601 QCNWNA587AWPZ AH BI701 QCNWNA056AWPZ AF BI702 QCNWN2715AWPZ AG BI703 QCNWN2505AWZZ AC - Sharp XL-UH250 | Service Manual - Page 105

-MEMO- XL-UH250 10 - Sharp XL-UH250 | Service Manual - Page 106

XL-UH250 [10] CHANGER MECHANISM / CD MECHANISM PARTS 122 A 101x2 107 B 102x5 C D E F G H 1 116 109 109-2 101x3 115 123 803x4 803x2 109-3 109-4 109-1 114 108 135 104 - Sharp XL-UH250 | Service Manual - Page 107

QSW-P9006AWZZ AF Disc Tray Guide Tray Outer Tray Guide Inner Tray Guide Main Base CD Mechanism Holder Top Plate Gear Plate Up/Down Holder Ass'y Stabilizer Up/Down Holder Ass'y Magnet Support Magnet Tray Lock Lever Gear PARTS, ITEM NO. ARE 1XX FOR CD MECHANISM PARTS, ITEM NO. ARE 3XX XL-UH250 12 - Sharp XL-UH250 | Service Manual - Page 108

XL-UH250 [11] CABINET PARTS A 206x5 CD CHANGER MECHANISM UNIT 229 205 CD MECHANISM WITH CUSHION 609x2 609X2 225 613x2 613x2 B 602x4 208 609x2 217 209 608x2 - Sharp XL-UH250 | Service Manual - Page 109

Ass'y - Front Panel AM Panel, FL Display AD Badge, SHARP AE Button, Function, A AE Button, Disc No. AD Indicator Washer (Not Replacement Item ) BK Changer Mechanism Unit AC Bracket, PWB Support AB Screw, Special AB Screw, M3 X10mm AC Screw, Special AC X10mm XL-UH250 14 - Sharp XL-UH250 | Service Manual - Page 110

XL-UH250 [12] SPEAKER BOX PARTS A B C D E F G H 1 2 3 4 5 6 15 - Sharp XL-UH250 | Service Manual - Page 111

RRMCGA120AWSA AR TINSKA025AWZZ AL FM Antenna AM Loop Antenna Remote Control Operation Manual [14] P.W.B. ASSEMBLY ( Not Replacement Item ) ! PWB-A B4 / Sub B5 CD MP3 CD Changer Motor (PWB Only) [15] OTHER SERVICE PARTS UDSKA0004AFZZ AZ CD Optical Pickup Lens Cleaner Disc XL-UH250 16 - Sharp XL-UH250 | Service Manual - Page 112

XL-UH250 17 - Sharp XL-UH250 | Service Manual - Page 113

-MEMO- XL-UH250 18 - Sharp XL-UH250 | Service Manual - Page 114

XL-UH250 -MEMO- 19 - Sharp XL-UH250 | Service Manual - Page 115

-MEMO- XL-UH250 20 - Sharp XL-UH250 | Service Manual - Page 116

XL-UH250 COPYRIGHT 2007 BY SHARP CORPORATION ALL RIGHTS RESERVED. No part of this publication may , photocopying, recording, or otherwise, without prior written permission of the publisher. SHARP CORPORATION Sharp-Roxy Corporation Sungai Petani, Kedah, Malaysia Printed in Malaysia A0702-1MX•RR•M SC

XL-UH250

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

XL-UH250

XL-UH250

PRECAUTIONS FOR USING LEAD-FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1]

Important Service Safety Precaution

...........

1-1

[2]

Specifications

...............................................

1-1

[3]

Names Of Parts

...........................................

1-2

CHAPTER 2. ADJUSTMENTS

[1]

CD Section

..................................................

2-1

[2]

Test Mode

....................................................

2-2

[3]

Standard Specification Of Stereo System

Error Message Display Contents

.................

2-4

[4]

CD Changer Mechanism Section

................

2-5

CHAPTER 3. MECHANICAL DESCRIPTION

[1]

Removing And Reinstalling The Main Parts

.....................................................................

3-1

[2]

Disassembly

................................................

3-2

CHAPTER 4. BLOCK DIAGRAM

[1]

Block Diagram

.............................................

4-1

CHAPTER 5. CIRCUIT DESCRIPTION

[1]

Waveforms Of Servo Circuit

........................

5-1

[2]

IC Voltage

....................................................

5-3

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1]

Notes On Schematic Diagram

.....................

6-1

[2]

Types Of Transistor And LED

......................

6-1

[3]

Schematic Diagram

.....................................

6-2

[4]

Charts Of Connecting Wires

......................

6-10

[5]

Wiring Side of PWB

...................................

6-12

CHAPTER 7. FLOWCHART

[1]

Troubleshooting

...........................................

7-1

CHAPTER 8. OTHER

[1]

Function Table Of IC

....................................

8-1

[2]

FL Display

....................................................

8-9

PARTS GUIDE

SERVICE MANUAL

No. S2709XLUH250/

Parts marked with "

" are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

CONTENTS

!

MICRO COMPONENT SYSTEM

MODEL

XL-UH250 Micro Component System consisting of

XL-UH250 (main unit) and CP-UH250 (speaker system).

XL-UH250

• In the interests of user-safety (Required by safety regulations in

some countries) the set should be restored to its original condition

and only parts identical to those specified be used.

SHARP CORPORATION