Stihl MS 251 Instruction Manual

Stihl MS 251 Manual

|

View all Stihl MS 251 manuals

Add to My Manuals

Save this manual to your list of manuals |

Stihl MS 251 manual content summary:

- Stihl MS 251 | Instruction Manual - Page 1

STIHL MS 231, 251 STIH) 2010-10 - Stihl MS 251 | Instruction Manual - Page 2

Fuel System 81 12.1 Air Filter 81 12.2 Baffle 81 12.3 Filter Base 81 12.4 Air Guide Shroud 83 12.4.1 Air Guide Shroud - Models with Manual Fuel Pump 85 12.5 Carburetor 88 12.5.1 Leakage Test 89 RA_737_00_01_01 MS 231, MS 231 C, MS 251, MS 251 C q © ANDREAS STIHL AG & Co. KG, 2010 - Stihl MS 251 | Instruction Manual - Page 3

and Installing 100 12.11 Fuel Intake 101 12.11.1 Pickup Body 101 12.11.2 Fuel Hose 101 12.11.3 Fuel Hoses - Manual Fuel Pump 105 12.11.4 Manual Fuel Pump 107 12.11.5 Tank Housing 108 13. Special Servicing Tools 110 14. Servicing Aids 112 2 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 4

. Refer to the latest edition of the relevant parts list to check the part numbers of any replacement parts. A fault on the machine may have several causes. To help locate the fault, consult the chapter on "Troubleshooting" and the "STIHL Service Training System" for all assemblies. Refer to the - Stihl MS 251 | Instruction Manual - Page 5

Preparations for servicing Remove the chain sprocket cover, saw chain and guide bar before carrying out repairs or mounting the machine to the assembly stand. Always use original STIHL replacement parts. They can be identified by the STIHL part number, the { logo and the STIHL parts symbol K This - Stihl MS 251 | Instruction Manual - Page 6

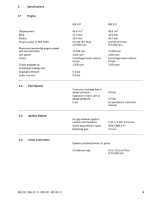

bar 0.5 bar as specified in instruction manual Air gap between ignition module and fanwheel: Spark plug (resistor type): Electrode gap: 0.30 (+ 0.05/- 0.10) mm NGK CMR 6 H 0.5 mm Speed-controlled Ematic oil pump Oil delivery rate: 8.0 (+/3.0) cm3/min at 10,000 rpm MS 231, MS 231 C, MS 251, MS - Stihl MS 251 | Instruction Manual - Page 7

/ tank housing 1.0 D 8x18 Collar stud for bar 16.0 D 8x18 Collar stud for bar 16.0 D 9x18 Collar stud for bar / engine housing 16.0 (repair solution) P 5x18 Cover, chain brake / engine housing 4.0 M 5 Filter base / baffle / carburetor 3.5 P 6x26.5 Handlebar / tank housing, right - Stihl MS 251 | Instruction Manual - Page 8

/ air guide shroud Spark plug / cylinder Ignition module/cylinder Cylinder / engine housing 2.0 1.6 12.0 4.5 11.0 1), 3) Remarks: 1) Screws with binding head 2) Micro-encapsulated screws 3) Waxed screws 4) Degrease crankshaft/flywheel and mount oil-free Q) QuickStop Super B) Quick chain adjuster - Stihl MS 251 | Instruction Manual - Page 9

install new clutch Replace the clutch springs Loud noises Clutch springs stretched Needle cage damaged Clutch shoe retainer broken Clutch shoes and carrier worn Replace all clutch springs Fit new needle cage Install new retainer or clutch Install new clutch 8 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 10

or install new clutch Replace the clutch springs Saw chain does not stop immediately when brake is activated Brake spring stretched or broken Fit new brake spring Brake band stretched or worn Clutch drum worn Fit new brake band Install new clutch drum MS 231, MS 231 C, MS 251, MS 251 C 9 - Stihl MS 251 | Instruction Manual - Page 11

travel on lockout lever QuickStop Super Braking action of coasting brake inadequate - lockout lever not depressed Brake cable overtensioned Remedy Readjust brake cable Reconnect or replace brake cable Adjust brake cable Adjust brake cable 10 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 12

before disassembling the oil pump. Condition Chain receives no oil Cause Remedy Oil inlet hole in guide bar is blocked Clean oil inlet hole Intake hose or pickup body clogged Fit new intake hose and pickup or intake hose ruptured body Valve in oil tank blocked Clean or replace valve Teeth - Stihl MS 251 | Instruction Manual - Page 13

correctly Guide pegs on replace pawls and torsion springs if necessary Lugs on carrier worn Install new carrier Spring loop in spring housing not Attach spring loop to carrier attached to carrier Spring in spring housing fatigued Install new spring housing 12 MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 14

very dirty Thoroughly clean complete starter mechanism At very low outside temperatures: Lubricating oil on rewind spring becomes viscous (spring windings stick together) or moisture has got pull rope carefully several times until normal action is restored MS 231, MS 231 C, MS 251, MS 251 C 13 - Stihl MS 251 | Instruction Manual - Page 15

new spring if necessary Spark plug sooted, smeared with oil Clean the spark plug or replace if necessary. If sooting keeps recurring, check air filter Fuel/oil mixture - too much oil Use correct mixture of fuel and oil Incorrect air gap between ignition Set air gap correctly module and flywheel - Stihl MS 251 | Instruction Manual - Page 16

diaphragm Tank vent faulty Replace tank vent Leak on fuel hose from tank to carburetor Seal connections or install new fuel hose Engine loses power during acceleration Sealing ring or spring in accelerator Install new carburetor pump worn or damaged MS 231, MS 231 C, MS 251, MS 251 C 15 - Stihl MS 251 | Instruction Manual - Page 17

- throttle shutter completely closed Tank vent faulty Clean the carburetor Reset low speed screw (L) correctly Reset idle speed screw (LA) correctly Replace tank vent Saw chain rotates at idle speed Leak on fuel hose from tank to carburetor Seal connections or install new fuel hose Engine idle - Stihl MS 251 | Instruction Manual - Page 18

wrong, flywheel out of adjustment - key in flywheel has sheared off Install new flywheel Engine running extremely rich, has Choke shutter does not open no power and a very low maximum speed Check carburetor and choke shaft, service or replace if necessary MS 231, MS 231 C, MS 251, MS 251 C 17 - Stihl MS 251 | Instruction Manual - Page 19

- Air filter - Fuel system - Carburetor - Ignition system Condition Cause Engine does not start easily, stalls Oil seals in engine damaged at idle speed, but operates normally at full throttle Engine pan leaking or damaged (cracks) Intake manifold damaged / bore blocked Remedy Replace the oil - Stihl MS 251 | Instruction Manual - Page 20

Drum - Remove and install the clutch drum, see instruction manual. - Remove the needle cage. - Clean the needle cage and crankshaft stub, b 14 - Lubricate the needle cage and crankshaft stub, b 14 1 : Pull boot (1) off the spark plug. - Unscrew the spark plug. 2310RA001 TG TOP 1 : Apply wrench to - Stihl MS 251 | Instruction Manual - Page 21

standstill. The braking time is in order if deceleration of the saw chain (less than a second) is imperceptible to the eye. If the chain brake does not operate properly, refer to troubleshooting, b 3.2. Contamination (with chain oil, chips, fine particles of abrasion, etc.) and smoothing of the - Stihl MS 251 | Instruction Manual - Page 22

(2) firmly. 2310RA014 TG 1 TOP - Engage the chain brake. The brake spring is now relaxed. : Use the assembly tool 1117 890 0900 to disconnect the brake spring (1) from the anchor pin (arrow). - Remove the brake spring from the brake lever. 2310RA015 TG MS 231, MS 231 C, MS 251, MS 251 C 21 - Stihl MS 251 | Instruction Manual - Page 23

a new engine housing. - Check the cam on the hand guard and replace the hand guard if necessary. 3 2 : Fit the strap (1) on the pivot the hand guard and brake lever. - Clean the pivot pins and disassembled parts, b 14 - Lubricate the pivot pins, b 14 1 2 1 : MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 24

2310RA025 TG : Lift the bearing boss of the hand guard (1) and this is not the case, replace the brake spring. - If parts in the reverse sequence. 2310RA026 TG : Push the flat spring (1) slightly to one side until the cam of the hand guard (arrow) slips passed it. MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 25

on Machines with QuickStop Super 2 2 - Troubleshooting, b 3.2 - Remove the shroud, b guard and replace the hand 1 guard if necessary. TOP 2310RA031 TG - Engage the chain brake. - Clean the pivot pins and disassembled parts, b 14 - Lubricate the pivot pins MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 26

guard bearing boss and the brake lever on to the pivot pins. 2310RA041 TG 2 : Hold the brake lever (2) so that the brake spring attachment point (arrow) is at the top. 2310RA036 TG 1 : Push the brake cable grommet (1) into its seat (arrow) as far as stop. MS 231, MS 231 C, MS 251, MS 251 C 25 - Stihl MS 251 | Instruction Manual - Page 27

case, replace the brake spring. - If the groove in the brake spring's anchor pin is worn, install a new engine housing, b 6.6 1 If problems occur on the coasting brake even though the brake band is in order, the reason may be the adjustment of the brake cable. - Troubleshooting, b 3.2 - Checking - Stihl MS 251 | Instruction Manual - Page 28

set free travel on the adjusting screw (1). 2310RA051 TG 2310RA050 TG other parts in carburetor, b 12.5 - Remove the throttle trigger, b 10.3 2310RA053 TG - Remove the switch lever, b 10.3.1 2 - Check the brake cable (1) and retainer (2), replace if necessary MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 29

(arrow) and then remove it from the retainer (4). : Fit the adjusting screw (1) and wind it home until the gap between the screw's hexagon to the right of the fuel hose (3) or, on versions with a manual fuel pump, to the right of the fuel hose (3) and fuel return MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 30

adjusting screw (2) - if this is not the case, the adjustment of the brake cable will vary. - Check position of fuel hose and correct if necessary, b 12.11.2 - Troubleshooting guide (arrow). - Install the switch lever, b 10.3.1 - Install the throttle trigger, b 10.3 MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 31

part of the sprocket cover (1). - If the chain catcher is damaged or worn, install a replacement chain catcher. 2310RA045 TG 5.5.1 Quick Chain Tensioner The quick chain tensioner is installed in the sprocket cover. 1 2 : Take out the screw (arrow). : Remove the cover plate (1) and adjusting - Stihl MS 251 | Instruction Manual - Page 32

5.6 Bar Mounting Stud - Remove the chain sprocket cover. 2 1 Repair solution If the thread in the engine housing is badly damaged or stripped it will not be possible to tighten the standard it down firmly. - Reassemble all other parts in the reverse sequence. MS 231, MS 231 C, MS 251, MS 251 C 31 - Stihl MS 251 | Instruction Manual - Page 33

system, carburetor, air filter and ignition system before looking for faults on the engine. - Troubleshooting, b 3.7 - Remove the shroud, b 6.4 Before removing the muffler, set the piston to top dead center to ensure that no dirt falls into the cylinder. - Remove and install the spark arresting - Stihl MS 251 | Instruction Manual - Page 34

2310RA072 TG 2310RA074 TG 6.2 Leakage Test Defective oil seals and gaskets or cracks in castings are the usual causes of leaks. Such faults allow supplementary air to enter the engine and upset the fuel-air mixture. This makes adjustment of the prescribed idle speed difficult, if not impossible. - Stihl MS 251 | Instruction Manual - Page 35

as for the vacuum test, b 6.2.2 3 2 - If the pressure drops, the leak must be located and the faulty part replaced. To find the leak, coat the suspect area with soapy water and pressurize the engine again. Bubbles will appear if a leak exists. - After finishing the test, push the ring to - Stihl MS 251 | Instruction Manual - Page 36

2405 with the collar (arrow) facing the engine. : Use press sleeve (2) 1122 893 2405 to install the oil seal (1). The seating face must be flat and free from burrs. - Degrease the crankshaft taper, b 14 - Reassemble all other parts in the reverse sequence. MS 231, MS 231 C, MS 251, MS 251 C 35 - Stihl MS 251 | Instruction Manual - Page 37

890 4400. - Clamp the puller arms. - Pull out the oil seal. : Fit press sleeve (1) 1122 893 2405 with the collar (arrow) facing the engine. : Use press sleeve (1) 1122 893 2405 to install the oil seal (2). The seating face must be flat and free from burrs. 36 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 38

b 4 - Remove the oil pump, b 11.3 - Remove the filter base, b 12.3 1 1 : Remove the screws (1) from the underside of the machine. - Remove the carburetor, b 12.5 - Remove the carburetor carrier, b 12.8 - Remove the air guide shroud, b 12.4 2310RA092 TG MS 231, MS 231 C, MS 251, MS 251 C 37 - Stihl MS 251 | Instruction Manual - Page 39

support the engine pan from below with one hand. 1 1 1 1 : Fit the retaining ring (1). - Reassemble all other parts in the reverse sequence. - Perform leakage test, b 6.2 6.6 Cylinder / Crankshaft - Remove the engine, b 6.5 Always install new oil it away. 38 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 40

without snap ring for replacement on opened engine. - Inspect the piston and piston rings and replace if necessary, b 6.8, b 6.9 Install the soft oil seal with the snap ring facing outwards and the hard oil seal with its open side facing the ball bearing. MS 231, MS 231 C, MS 251, MS 251 C 39 - Stihl MS 251 | Instruction Manual - Page 41

the cylinder bore is tapered to ease installation. - Lubricate the piston, piston rings and cylinder wall with oil, b 14 : Install the piston rings so that the radii at the ring gaps meet at the fixing the straight and tapered crankshaft stubs as far as stop. 40 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 42

rod and needle bearing form an inseparable unit. When fitting a replacement crankshaft, always install new ball bearings and oil seals. 2310RA112 TG 3 : Position the engine pan (1) so that the tab (2) lines up with the shoulder (3) on the cylinder. MS 231, MS 231 C, MS 251, MS 251 C 41 - Stihl MS 251 | Instruction Manual - Page 43

piston. - Inspect the piston rings and replace if necessary, b 6.9 Installing - Pull out the needle cage , check it and replace if necessary. 1 2710RA118 TG 2710RA418 TG out. : Lubricate the needle cage (1) with oil and push it into the connecting rod. 42 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 44

into the sleeve until the magnet butts against the end of the guide slot. Use a suitable base. - Place the piston on the point towards the flat face. - Lubricate the piston pin (2) with oil. 5904RA090 TG 2710RA419 TG : Fit the piston pin (2) on the assembly MS 231, MS 231 C, MS 251, MS 251 C 43 - Stihl MS 251 | Instruction Manual - Page 45

sleeve against the piston boss, hold the piston replace if necessary, b 6.9 - Install the crankshaft and new oil seals, b 6.5 : Position the new piston rings so that the radii face upward (arrows). - Install the crankshaft, b 6.6 - Install the engine, b 6.5 44 MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 46

voltages which occur can cause serious or fatal accidents. Troubleshooting on the ignition system should always begin at the spark plug, b 3.5 - Remove the fan housing, b 8.2 1 7.1 Ignition Timing Ignition timing is fixed and cannot be adjusted during repair work. Since there is no mechanical wear - Stihl MS 251 | Instruction Manual - Page 47

the guides (arrows) and remove the retainer (3). - Check ignition lead, replace ignition module if necessary - Check the spark plug boot and replace if 2 - Troubleshooting, b 3.5 Installing 1 1 2 N S 1 : Position the retainer (1) against the cylinder and attach its pegs to the bosses. 2 - Stihl MS 251 | Instruction Manual - Page 48

all other parts in the reverse sequence. The engine may start and accelerate during the test. If a spark is visible, the ignition system is in order. - If no spark is visible in the window (2), check the ignition system with the aid of the troubleshooting chart, b 7.8 7.4 Testing the Ignition - Stihl MS 251 | Instruction Manual - Page 49

- risk of electric shock. : Use suitable pliers to pull the leg spring out of the spark plug boot. - Coat the inside of the spark plug boot with STIHL press fluid, b 14 : Hold the ignition lead and leg spring together and push them into the spark plug boot. 48 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 50

flywheel, b 7.3 - Reassemble all other parts in the reverse sequence. 2310RA110 TG 0001RA167 TG 2310RA422 TG 1 The flywheel and magnet poles (arrows) must not be damaged or have turned blue. Replace flywheel if necessary. : Unscrew the flywheel nut (1). MS 231, MS 231 C, MS 251, MS 251 C 49 - Stihl MS 251 | Instruction Manual - Page 51

switch lever off the shaft on the filter base, b 10.1 - Pull the carburetor towards the control handle - take care not replace the wiring harness, b 7.7.2. : Pull the short circuit wire (1) and ground wire (2) out of the guides (arrows) in the air guide shroud. 50 MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 52

guide (arrow). : Remove the Master Control lever (2). 1 3 : Position the wiring harness (1) in the retainer (2) so that about 5 mm (a) of the protective tube (3) is held as shown - the protective tube must be pushed into the grommet as far as stop. 2310RA141 TG MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 53

they snap into place. - Position filter base in the carburetor box. 2310RA145 TG 1 : Fit the short circuit wire (1) in the guides (arrows). - Install the switch lever, b 10.1 - Fit the contact spring, b 7.7.4 - Install the filter base, b 12.3 2310RA147 TG 52 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 54

the guide. : Swing the filter base (1) to one side. - Check operation of switch lever, b 10.1 - Reassemble all other parts in the reverse sequence. 1 2 : Push the sleeve (1) out of the contact spring (2). - Check the contact spring and replace it if necessary, MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 55

sleeve must touch the contact spring (arrow) in position "0". - Reassemble all other parts in the reverse sequence. 1 Before pushing the contact spring (1) fully home, lift it a little and ease it over the switch level - no more than 2 mm. 54 2310RA153 TG MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 56

7.8 Ignition System Troubleshooting Engine does not run Stop switch: - in position "F"? Check the spark plug: - Smeared with oil, black? - Sooted? - Electrode gap correct? - Contacts shorted? - Clean, readjust or replace the plug, b 7.4 Check the spark plug boot: - Firmly seated on plug (leg - Stihl MS 251 | Instruction Manual - Page 57

- Spark plug boot: Holes/cracks? - Resistance: spark plug boot to ground: spec. 1.5 - 12 kΩ - Check resistance of ignition lead (spark plug boot and ignition module removed) Spec.: < 10 Ω, If necessary, install new spark plug boot and/or ignition module, b 7.5 2 3 56 MS 231, MS 231 C, MS 251, MS - Stihl MS 251 | Instruction Manual - Page 58

- replace the wiring harness if necessary, b 7.7.2 Powerful yes spark? no Install new ignition module b 7.3 yes Machine runs trouble-free, no further action necessary Engine runs? MS 231, MS 231 C, MS 251, MS 251 C no - Look for fault in fuel system or carburetor - Check engine for leaks - Stihl MS 251 | Instruction Manual - Page 59

oil STIHL replace if necessary. 2310RA202 TG 2310RA201 TG - Lift the hand guard a little and fit the fan housing in position. : Insert screw (1) with sleeve and screws (arrows) and tighten them down firmly. - Reassemble all other parts in the reverse sequence. 58 MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 60

spring clip's guide loop must be part of the spring clip (short arrow) must engage the starter post's groove. : Push the straight part (3) of the spring clip over the starter post until it snaps into the groove. - Reassemble all other parts in the reverse sequence. MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 61

as far as stop (arrow). : Fit the E-clips (2). 2710RA274 TG : Fit the washer (3). : Fit the E-clip (4). - Do not overstretch the retaining ring. - Reassemble all other parts in the reverse sequence. 60 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 62

The rewind spring may pop out and unwind. - Check the rope rotor and replace if necessary. - Coat bore in rope rotor with STIHL special lubricant, b 14 Installing - Install the pawl(s) and spring clip, b anchor point for the spring. - Fit the cover washer. MS 231, MS 231 C, MS 251, MS 251 C 61 - Stihl MS 251 | Instruction Manual - Page 63

the rewind spring, b 8.7 - Reassemble all other parts in the reverse sequence. 1 165RA227 TG : Tie : Thread the starter rope (1) through the guide bushing (arrow). 1 2310RA216 TG 8.7 Tensioning will otherwise spin back and may damage the rewind spring. 62 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 64

, hold the rope rotor steady and take off one turn of the rope. - Reassemble all other parts in the reverse sequence. 8.8 Replacing the Rewind Spring - Troubleshooting, b 3.4 The replacement spring, in a spring housing, comes ready for installation. Installing new rewind spring 1 2 - Lubricate the - Stihl MS 251 | Instruction Manual - Page 65

2310RA231 TG - Lubricate the replacement spring with frame with a few drops of STIHL special lubricant before installing, b 14 : Position the replacement spring with frame in the the rope rotor, b 8.5 - Reassemble all other parts in the reverse sequence. 64 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 66

out, refit it in the frame as follows: 1 - Install the rope rotor, b 8.5 - Reassemble all other parts in the reverse sequence. : Fit the anchor loop in its seat (arrow) in the frame. : Fit the for installing a new rewind spring on models without ErgoStart. MS 231, MS 231 C, MS 251, MS 251 C 65 - Stihl MS 251 | Instruction Manual - Page 67

replaced. - Check the AV spring and plug, replace if necessary. Installing 2 9.2 AV Spring on Fuel Tank - Remove the handlebar, b 9.3 1 9.1 AV Spring on Oil other parts in the reverse sequence. 2310RA233 TG : Unscrew the AV spring (1) with bearing plug (2). 66 MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 68

the shroud, b 6.4 - Remove the air filter, b 12.1 2310RA240 TG 2310RA238 TG 2310RA242 TG : Push the AV spring (1) upwards and lift it out of the guide (arrow). : Remove the AV spring (1) between the engine housing and tank housing. - Check the AV spring and plug, replace if necessary. Installing - Stihl MS 251 | Instruction Manual - Page 69

Use STIHL press parts in the reverse sequence. : Screw the bearing plug (1) into the spring as far as stop. - Install the handlebar, b 9.4 1 2310RA245 TG 5902RA247 TG : Pry out the stop buffer (1) at the ignition and clutch sides. - Install new stop buffers. 68 MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 70

2310RA250 TG 2310RA252 TG 2310RA242 TG 1 : Push out the buffers (1) from the underside (arrows). - Check the buffers (1) and replace if necessary The tapered ends (arrows) must be properly seated on the other sides of the bores. : Take out the screw (1). MS 231, MS 231 C, MS 251, MS 251 C 69 - Stihl MS 251 | Instruction Manual - Page 71

2310RA159 TG 0001RA232 TG 1 : Ease the handlebar (1) sideways and place it in the guide (arrow). - Insert the screws and tighten them down firmly. : Push the handlebar (1) out of the lower guide. - Remove the handlebar (1), check it and replace if necessary. 70 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 72

Control Lever - Check the filter base and replace 2 The positions of the Master Control it if necessary lever are described in the instruction manual. Installing 1 10.1.1 Removing and Installing - Remove the air filter, b 12.1 - Position filter base in the carburetor box. - Remove the - Stihl MS 251 | Instruction Manual - Page 73

throttle rod (1) to the throttle trigger (2) and fit it in the guide (arrow). 1 1 2 2310RA166 TG 2310RA169 TG : Pull the lockout lever (1) out of its mounts (arrows). : Attach the torsion spring (1) to the trigger (2) - note the installed position (arrow). 72 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 74

2 1 - Reassemble all other parts in the reverse sequence. 2 1 . 1 : Take the throttle rod (1) out of the guide (arrow) and disconnect it from the throttle trigger (2). 2 freely, replace trigger if necessary. - Check torsion spring and replace if necessary. MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 75

. - Check operation - Reassemble all other parts in the reverse sequence. 2310RA182 TG 2310RA179 TG 2310RA174 TG The brake cable (1) must be fully engaged in the guide (arrows) or be below the drift - take care not to damage replace it if necessary 74 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 76

the torsion spring (2). - Inspect the lockout lever, torsion spring and bushing, replace as necessary. 2310RA189 TG The torsion spring (arrow) must locate against the tank at both sides. - Reassemble all other parts in the reverse sequence. - Check operation MS 231, MS 231 C, MS 251, MS 251 C 75 - Stihl MS 251 | Instruction Manual - Page 77

, b 12.2 1 2 1 2310RA196 TG : Pull the short circuit wire (1) and ground wire (2) out of the guides (arrows). - Put the filter base to one side so that the wires are not under tension. 2310RA195 TG 2 : Pry the filter base (1) out of the buffer (2). 76 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 78

is pulled. 2310RA293 TG 2310RA296 TG : Pry the throttle rod (1) out of the carburetor carrier (2). : Push the throttle rod (1) into the guide (2) in the carburetor carrier until it snaps into position. - Reassemble all other parts in the reverse sequence. MS 231, MS 231 C, MS 251, MS 251 C 77 - Stihl MS 251 | Instruction Manual - Page 79

the suction hose. - Pull off the pickup body (1), check it and replace if necessary. - Reassemble in the reverse sequence. : Remove the shim (1). 1 2310RA300 TG - Push the oil suction hose (1), pickup body first, through the housing bore (arrow). 78 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 80

. 2310RA307 TG 2310RA304 TG 2 : Pull the oil pump (1) off the oil suction hose (2). 1 : Position the oil suction hose (1) so that the straight sides of the lugs (arrows) locate against the engine housing. : Push the oil suction hose (1) onto the nipple. MS 231, MS 231 C, MS 251, MS 251 C 79 - Stihl MS 251 | Instruction Manual - Page 81

must be replaced if it is faulty. - Open the oil tank cap and drain the oil tank b 1. : Drive the new valve into the bore to a depth of 1 +/- 0.1 mm (a). - Reassemble all other parts in the carefully drive in the new valve from outside - note installed depth. 80 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 82

it if necessary : Rotate the air filter (1) counterclockwise and lift it away. - Check the air filter and clean or replace if necessary - see instruction manual. - Reassemble in the reverse sequence. 12.3 Filter Base - Remove the air filter, b 12.1 2 : Pull the filter base (1) out of the buffer - Stihl MS 251 | Instruction Manual - Page 83

the buffer. 2310RA318 TG : Use punch-down tool 5910 890 4000 to press the ground wire (1) into the guides (arrows) so that the marking (2) is at the edge of the guide. - Check operation of switch lever. - Reassemble all other parts in the reverse sequence. 82 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 84

(1) (about 15 cm long) around the back of manifold flange. - Coat manifold flange with STIHL press fluid to simplify installation, b 14 2310RA320 TG : Take out the screws (1). - Pull the fuel hose out of the air guide shroud. - Remove the air guide shroud. MS 231, MS 231 C, MS 251, MS 251 C 83 - Stihl MS 251 | Instruction Manual - Page 85

. 1 : Insert and tighten down the screws (2) firmly. - Install the carburetor carrier, b 12.8 2310RA328 TG 2 - Install the throttle rod, b 10.3.4 - Coat the grommet with STIHL press fluid to simplify installation, b 14 - Install the carburetor, b 12.5 84 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 86

12.4.1 Air Guide Shroud - Models with Manual Fuel 2 Pump 1 - Remove the fan housing, b 8.2 3 - Pull the filter base off the studs and put it to one side with the wiring harness still attached, b 12.3 - Remove the carburetor, b 12.5 - Pull the boot off the spark plug. : Take out the screw (1). - Stihl MS 251 | Instruction Manual - Page 87

it and replace if necessary. Installing : To fit the manifold (2) through the air guide shroud's opening, wind a piece of string (1) (about 15 cm long) around the back of manifold flange. 1 2310RA341 TG - Remove the grommet, check and replace if necessary. 86 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 88

screws (2) firmly. : Starting at the elbow connector (2), push the fuel return hose (1) into the guides (arrows). - Position the fuel return hose snugly - without a loop between the air guide shroud and grommet. Do not kink or pinch the fuel return hose. - Install the carburetor carrier, 2 b 12 - Stihl MS 251 | Instruction Manual - Page 89

2310RA352 TG Disconnect the fuel hose only when the tank cap is open. : Remove the carburetor (1). Stub (3) must engage bore in manifold flange. - Check the carburetor and service or replace if necessary. - Install a new fuel hose, b 12.11.2 2310RA353 TG 88 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 90

- Test the tank vent if necessary, b 12.10.1 - After completing the test, push the ring (1) to the left to vent the system and then pull the fuel hose off the carburetor. - Install the filter base, b 12.3 - Reassemble all other parts in the reverse sequence. MS 231, MS 231 C, MS 251, MS 251 C 89 - Stihl MS 251 | Instruction Manual - Page 91

a manual fuel pump, check the nipple (2) and replace the end cover if necessary. - Note installed positions of metering diaphragm (2) and gasket (1). : Position the gasket (1) and metering diaphragm (2) so that pegs (arrows) engage the small holes in the tabs. 90 MS 231, MS 231 C, MS 251, MS 251 - Stihl MS 251 | Instruction Manual - Page 92

3 Installing 12.6.3 Pump Diaphragm - Troubleshooting, b 3.6 - Remove the carburetor, b 12.5 2310RA261 TG 1 carburetor, remove them very carefully. 2310RA265 TG 2310RA264 TG 1 2 : Remove the inlet needle (1). : Remove the spring (2). Inspect and replace MS 231, MS 231 C, MS 251, MS 251 C 91 - Stihl MS 251 | Instruction Manual - Page 93

levers. 2 2310RA267 TG 2310RA269 TG 2310RA271 TG : Use a needle to remove the fuel strainer (1) from the carburetor body. Clean or replace the fuel strainer. - Reassemble in the reverse sequence. : Remove the retaining ring (1). : Pull off the lever (2). 92 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 94

carburetor cannot be adjusted properly, the problem may be the adjusting screws. The high speed screw H has a limiter cap, which has to be removed before the screw is removed. : Inspect the tip (arrow) and O-ring (1) for damage or wear and replace screw L (1). MS 231, MS 231 C, MS 251, MS 251 C 93 - Stihl MS 251 | Instruction Manual - Page 95

cap - left-hand thread. : Inspect the tip (arrow) and O-ring (1) for damage or wear and replace the high speed screw (H) if necessary. Do not turn the puller any further - the high speed screw the reverse sequence. - Carry out the basic setting, b 12.7.1 94 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 96

cap. The carburetor and air filter are installed, the adjusting screws fitted and the new limiter cap preinstalled. - Check chain tension and adjust if necessary. - Inspect the spark arresting screen (if fitted) and clean or replace if necessary, b 3.7 or b 6.1 - Check the air filter and clean or - Stihl MS 251 | Instruction Manual - Page 97

before carrying out any adjustments: - Troubleshooting, b 3.6 - Check chain tension and adjust if necessary. - Inspect the spark arresting screen (if fitted) and clean or replace if necessary, b 3.7 or b 6.1 2310RA285 TG - Check the air filter and clean or replace if necessary, b 12.1 Standard - Stihl MS 251 | Instruction Manual - Page 98

the manifold (2) through the carburetor carrier's opening, wind a piece of string (1) (about 15 cm long) around the back of manifold flange. 2310RA289 TG : Position the carburetor carrier (1) so that the semi-circles (arrows) locate against the studs (2). MS 231, MS 231 C, MS 251, MS 251 C 97 - Stihl MS 251 | Instruction Manual - Page 99

A damaged intake manifold can result in engine running problems. - Troubleshooting, b 3.6 or b 3.7 - Remove the shroud, b 6.4 - Remove the carburetor, b 12.5 - Remove the carburetor carrier, b 12.8 - Remove the air guide shroud, b 12.4 Models with manual fuel pump, b 12.4.1 : Inspect and clean the - Stihl MS 251 | Instruction Manual - Page 100

(arrows) and tighten them down firmly. - Install the air guide shroud, b 12.4 Models with manual fuel pump, b 12.4.1 - Install the carburetor carrier, b 12.8 - Reassemble all other parts in the reverse sequence. 12.10 Tank Vent 12.10.1 Testing 2310RA360 TG 1 : Push the nipple (1) 0000 855 9200 - Stihl MS 251 | Instruction Manual - Page 101

Pressure test 2 - Coat sealing ring of new tank 1 vent with STIHL press bar. If this pressure remains constant for at least 20 seconds, the tank, including the tank vent, is airtight. If the pressure drops, the leak must be located and the faulty part replaced MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 102

into the tank. Close the tank and shake the saw vigorously. - Remove the pickup body, b 11.1 - Remove the carburetor carrier, b 12.8 1 : Take out the screws (1). - Remove the air guide shroud, b 12.4 Models with manual fuel pump, b 12.4.1 2310RA374 TG MS 231, MS 231 C, MS 251, MS 251 C 101 - Stihl MS 251 | Instruction Manual - Page 103

replace if necessary. Installing 1 1 1 2310RA057 TG 2310RA380 TG 2310RA377 TG When the tank housing is lowered, the brake cable grommet is pulled out of the adjusting screw - this may change the adjustment hose (2). - Remove the pickup body, b 12.11.1 102 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 104

TG - Use STIHL press fluid to simplify assembly, b 14 : Line up the fuel suction hose (1) and push it into the housing bore as far as stop - the flange must engage the guide (arrow). : Push Push the connector (1) into the fuel hose (2) as far as stop. MS 231, MS 231 C, MS 251, MS 251 C 103 - Stihl MS 251 | Instruction Manual - Page 105

b 12.11.1 2 2 1 1 - Install the air guide shroud, b 12.4 Models with manual fuel pump, b 12.4.1 - Install the carburetor carrier, b 12.8 2310RA388 TG 2310RA387 TG : Pass the - Close the tank cap. - Reassemble all other parts in the reverse sequence. 104 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 106

the carburetor carrier, b 12.8 1 : Pull the connector (1) off the fuel return hose (2). 2310RA390 TG - Remove the air guide shroud, b 12.4.1 - Lower the tank housing, b 12.11.2 : Remove the fuel hose (1), b 12.11.2. 1 2310RA394 TG 2310RA391 TG 1 : Pry out the grommet (1). - Replace the - Stihl MS 251 | Instruction Manual - Page 107

1 2310RA398 TG 2310RA395 TG : Remove the fuel suction hose (1), b 12.11.2 2 2 1 - Use STIHL press fluid to simplify assembly, b 14 2310RA401 TG : Fit the grommet (1) in the hole (arrow) in the brake cable (2). : Install the fuel hose (1), b 12.11.2 106 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 108

recess (arrow). : Push the fuel pump (1) into the air guide shroud (2) until the tabs engage. 312 2310RA408 TG 2310RA406 TG 6 45 : Squeeze the tabs (arrows) together and pull out the manual fuel pump (1). - Check the oil fuel pump and replace if necessary. : Push the fuel return hose (1) onto - Stihl MS 251 | Instruction Manual - Page 109

transfer those parts from the old tank housing that are not 1 included with the replacement - see : Push the AV spring (1) into the parts list. bearing seat (2) so that the lug (3) engages the recess (arrow). 2310RA232 TG : Take out the screw (1). 108 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 110

and tighten down the screw (1) firmly. - On models with QuickStop Super, connect the brake cable to the brake lever, b 5.4.2 - Install the air guide shroud, b 12.4 Models with manual fuel pump, b 12.4.1 - Reassemble all other parts in the reverse sequence. MS 231, MS 231 C, MS 251, MS 251 C 109 - Stihl MS 251 | Instruction Manual - Page 111

springs Leakage Test Protecting the oil seal (clutch side) Installing oil seal (clutch side/ignition side) Spark plug 1) Protecting the oil seal (ignition side) Clamping machine to assembly stand Testing ignition system Testing ignition system 110 MS 231, MS 231 C, MS 251, MS 251 C - Stihl MS 251 | Instruction Manual - Page 112

Holding saw for repairs Removing oil seals Removing oil seals Removing oil seals Pull off the limiter cap. Removing bar mounting studs Removing flywheel Add-on for screwdriver (adjusting carburetor) Removing pickup body Remarks: 1) Use for releasing only. MS 231, MS 231 C, MS 251, MS 251 C 111 - Stihl MS 251 | Instruction Manual - Page 113

14. Servicing Aids No. Description Part No. 1 STIHL multipurpose grease 0781 120 1109 2 Lubricating grease (225 g tube) 0781 120 1111 3 STIHL special lubricant 0781 417 1315 4 STIHL press fluid OH 723 5 Dirko HT red sealant 0781 957 9000 0783 830 2000 Application Oil seals, sliding and - Stihl MS 251 | Instruction Manual - Page 114

englisch / english 0455 737 0123. M0. M10. xxx.

STIH)

STIHL MS 231, 251

2010-10