Dell PowerVault 122T LTO Dell PowerVault 122T DLT VS80 Autoloader User's Guide - Page 19

Error, Description, Details, Re-inventory, Configuration, Preposition - manual

|

View all Dell PowerVault 122T LTO manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

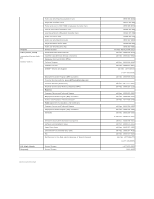

Error Description Code 3 0 81 Invalid Command Error. 3 0 82 Device Status Not Suitable to Execute This Command. 3 0 83 Inventory Not Valid. 3 0 84 Source Empty. 3 0 85 Destination Full. 3 0 86 Import/Export Slot Access Rejected. 3 0 87 Operation Timeout. 3 0 88 Communications Error During Loop-Back. 3 0 89 System Test Timeout. 3 0 8F Recovered Loader Error. 3 0 90 Mechanical Initialization Failure. 3 0 91 Inventory Scan Failure. 3 0 92 Preposition Failed. 3 0 93 Cartridge Load Error. 3 0 94 Cartridge Unload Error. 3 0 95 Import Error. 3 0 96 Export Error. 3 0 A0 Carousel Motion Failure. 3 0 A1 Cartridge Transport Position Error. 3 0 A2 Gripper Position Error. 3 0 A3 Cartridge Pick Error. 3 0 A4 Import/Export Slot Position Error. 3 0 A5 Fan Error. 3 0 B0 ROM Error. 3 0 B1 RAM Error. 3 0 B2 NVRAM Error. 3 0 B3 Controller Timer Failure. 3 0 B4 Loader To Drive Communication IC Error. 3 0 B5 Display Error. 3 0 B6 Memory Error. 3 0 B7 Timeout on Autoloader Command 3 0 BC Drive Bug-Checked. 3 0 BF Fatal Error. Details This error indicates that the autoloader received an undefined command or an invalid parameter within a command. If the robotics are busy, some commands cannot be executed at the same time. This error indicates a probable violation. This is not an error condition, but does result in Busy being reported to the host for the requested SCSI command. The cartridge inventory is not valid because of manual changes or previous fatal errors. Update the inventory using the Re-inventory option in the Configuration menu. See "Creating an Inventory of Cartridges" or power cycle. There is no cartridge in the location from which a cartridge move was issued. The location to which a cartridge move was issued already contains a cartridge. User attempted to access the Import/Export slot, but media removal was prevented by the host. A command did not complete in the required amount of time. Power cycle the autoloader and attempt the operation again. If the error recurs, contact your technical support representative. There was a communication timeout between the drive and loader during the System Test. Loader error recovery successful. Your diagnostic tool can provide details of the original loader error. The robotics were not able to move to the safe mechanical initialization position. Manual intervention is necessary. Fatal robotic error occurred during the inventory scan. Belt positioning error occurred during Preposition command. A failure occurred while trying to load a cartridge a slot to the drive. A failure occurred while trying to unload a cartridge from the drive to its slot. An error occurred while trying to import a data cartridge to a carousel slot. An error occurred while trying to export a data cartridge from its carousel slot. Can be caused by an empty slot that is expected to be full. Error occurred during carousel movement (Position Not Found). Could be caused by a missing or misaligned cartridge carrier, or an obstruction, or unexpected cartridge in either the carousel path or Import/Export slot. Cartridge transport element is unable to reach its desired position. Failure occurred while trying to place a cartridge into or remove a cartridge from the drive or a slot. Gripper unable to reach position. Error occurred while trying to pull a cartridge from the drive or a carousel slot. The Import/Export slot door was not in the requested position during device operation. Can be caused by manually opening the door, or a cartridge or other obstruction is blocking the door. Try removing the cartridge or obstruction, then power cycle or reset the autoloader. Autoloader Processor Detected a Fan Error. Power cycle the autoloader and attempt the operation again. If the error recurs, contact your technical support representative. Power cycle the autoloader and attempt the operation again. If the error recurs, contact your technical support representative. Power cycle the autoloader and attempt the operation again. If the error recurs, contact your technical support representative. An unrecoverable failure has occurred in the controller timer circuit. Failure in IC handling loader to drive communication. Power cycle the autoloader and attempt the operation again. If the error recurs, contact your technical support representative. Power cycle the autoloader and attempt the operation again. If the error recurs, contact your technical support representative. Power cycle the autoloader and attempt the operation again. If the error recurs, contact your technical support representative. Power cycle the autoloader and attempt the operation again. If the error recurs, contact your technical support representative. Power cycle the autoloader and attempt the operation again. If the error recurs, contact your technical support representative. Back to Contents Page