1994 Chevrolet Suburban Owner's Manual - Page 353

1994 Chevrolet Suburban Manual

Page 353 highlights

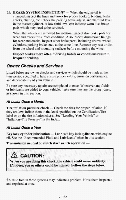

12. EGR SYSTEM INSPECTION* - Conduct EGR SYSTEM CHECK as described in the Service Manual. 13. ELECTRONIC VACUUM REGULATOR VALVE (EVRV) INSPECTION* - Inspect filter for excessive contamination or plugging. If required, clean element witha solution of biodegradable soap and water, let dry and reinstall element. 14. ENGINE TIMING CHECK AND DISTRIBUTOR CHECK (SOME MODELS)*$ - Adjust timing to underhood label specifications. for cracks, Inspect the inside and outsideof the distributor cap and rotor carbon tracking and corrosion. Clean or replace as needed, 15. FUEL TANK, CAP AND LINES INSPECTION*$ - Inspect the fuel tank, cap and lines for damage or leaks. Remove fuelcap, inspect gasket for an even filler neck imprint, and any damage. Replace parts as needed. 16. THERMOSTATICALLY CONTROLLED AIR CLEANER INSPECTION*A - (If so equipped.) Inspect all hoses and ducts for proper hook-up. Be sure the valve works properly. 17. SINGLE ENGINE ACCESSORY DRIVE (SERPENTINE) BELT INSPECTION* - Inspect belt. Lookfor cracks, fraying, wear, and proper tension. Adjust or replace as needed. 18. EVAPORATIVE CONTROL SYSTEM (ECS) INSPECTION*- for proper hookup, routing, Check all fuel and vapor lines and hoses and condition. Check that the purge valve works properly, if equipped. Replace as needed. 19. SHIELDS AND UNDERHOOD INSULATION INSPECTIONAV - Inspect shields and underhood insulation for damage or looseness. Adjust or replace as required. 20. AIR INTAKE SYSTEMINSPECTIONAV - Check the air intake system installation to see that gasketsare sealed properly and allhose connections, fasteners, and other components are tight. Also check to be sure that the air cleaner housing is properly seated, thatthe cover fits tightly, and the wing nuts are tight. Tighten connections andfasteners or replace damaged parts as required. '% An Emission Control Service ANoise Emission Control Service P'Applicable only to vehicles sold in the United States $The California Air Resources Boardhas determined that the failureto perform this maintenance item will not nullify the emission warranty or limit recall liability prior to the completion of the vehicle useful life. General Motors, however, urges thatall recommended maintenance services be performed at the indicated intervals and the maintenance be recorded. 7-20