Bosch 11239VS Operating Instructions - Page 7

Operating Instructions - rotary hammer

|

UPC - 000346316780

View all Bosch 11239VS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

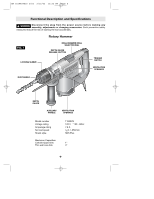

BM 1619929510 2/03 2/12/03 12:23 PM Page 7 Operating Instructions VARIABLE SPEED CONTROLLED TRIGGER SWITCH Your tool is equipped with a variable speed trigger switch. The tool can be turned "ON" or "OFF" by squeezing or releasing the trigger. The speed can be adjusted from the minimum to maximum nameplate RPM by the pressure you apply to the trigger. Apply more pressure to increase the speed and release pressure to decrease speed. INSTALLING ACCESSORIES Clean the insert shank end of the accessory to remove any debris, then lightly grease with a light oil or lubricant (Fig. 2). FIG. 2 Insert accessory into the tool holder through the dust shield, while twisting and pushing inward until it locks automatically into place. Pull outward on the accessory to be certain it is locked into the tool holder (fig. 3). FIG. 3 NOTE: The high efficiency available from the rotary hammers can only be obtained if sharp and undamaged accessories are used. The "cost" to maintain sharp and undamaged accessories is more than offset by the "time saved" in operating the tool with sharp accessories. REMOVING ACCESSORIES ! WARNING Accessories may be hot after use. Avoid contact with skin and use proper protective gloves or cloth to remove. To remove an accessory, pull and hold locking sleeve backward and pull bit forward. All accessories should be wiped clean after removing. DRILL/HAMMER DRILL SELECTION DIAL The selector dial allows the tool to be set for various drilling applications. Shift the dial right or left depending on the below applications. ! CAUTION Do not operate the selection dial until the tool come to a complete stop. Shifting during rotation of the chuck can cause damage to the tool. Do not use demolition or chipping bits such as bull points, chisels, spades, gouges, etc. Drill only action: For drilling in woods, metals, plastics or other non concrete materials. Drill with hammer action: For drilling in concrete, asphalt, tile or other similar hard materials. SLIP CLUTCH The tool has a internal pre-set slip clutch. The output spindle will stop rotating if the accessory binds and overloads the tool. AUXILIARY HANDLE The tool must be supported with the auxiliary handle, which can be swiveled 360˚. To reposition and/or swivel the handle, loosen the hand grip, move the handle to the desired position along the barrel and securely retighten the hand grip. DEPTH GAUGE Your drilling depth can be pre-set and/or repeated by using the depth gauge. Setting depth: After the auxiliary handle is installed, push down on the depth gauge -7-