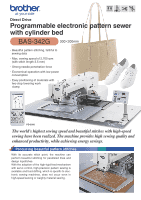

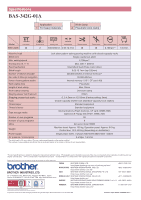

Brother International BAS-342G Brochure - English - Page 3

Easy and accurate positioning of materials

|

View all Brother International BAS-342G manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

Easy and accurate positioning of materials By setting the work clamp operation to two-step lowering, the work clamp can be lowered to pause at an intermediate position and then lowered to the lowest position. By setting an optimal height for the intermediate position, quick and accurate positioning of materials is possible. This reduces additional clamping operations due to incorrect positioning of the material, shortening the total cycle time. Stable thread tightening available with low-tension sewing Stable thread tightening even with low-tension sewing has been realized, with the high-rigid feed mechanism with servo control and the needle bar / thread take-up mechanism that has optimal timing and stroke. Uniform thread tightening even at overlapping parts of materials The setting of the height of the stepping presser foot can easily be made by putting a value on the operation panel. By setting a suitable height of the presser foot for the thickness of the material, excessive or insufficient pressing by the presser foot can be prevented, enabling a finish with uniform thread tightening. By using the programmer PD-3000*, the height of the stepping presser foot can be set in sewing data. The height can be set so that it changes according to the changes of the thickness of the material. * The programmer is an optional product. Adjustment of driver needle guard without tilting the machine head The driver needle guard can easily be adjusted from the side of the bed, without tilting the machine head. The adjustment of the clearance between the needle and the hook tip is also possible without tilting the machine head. For adjustment of the clearance between the needle and hook tip For adjustment of the driver needle guard