Brother International BAS-370E Instruction Manual - English - Page 11

Brother International BAS-370E Manual

|

View all Brother International BAS-370E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

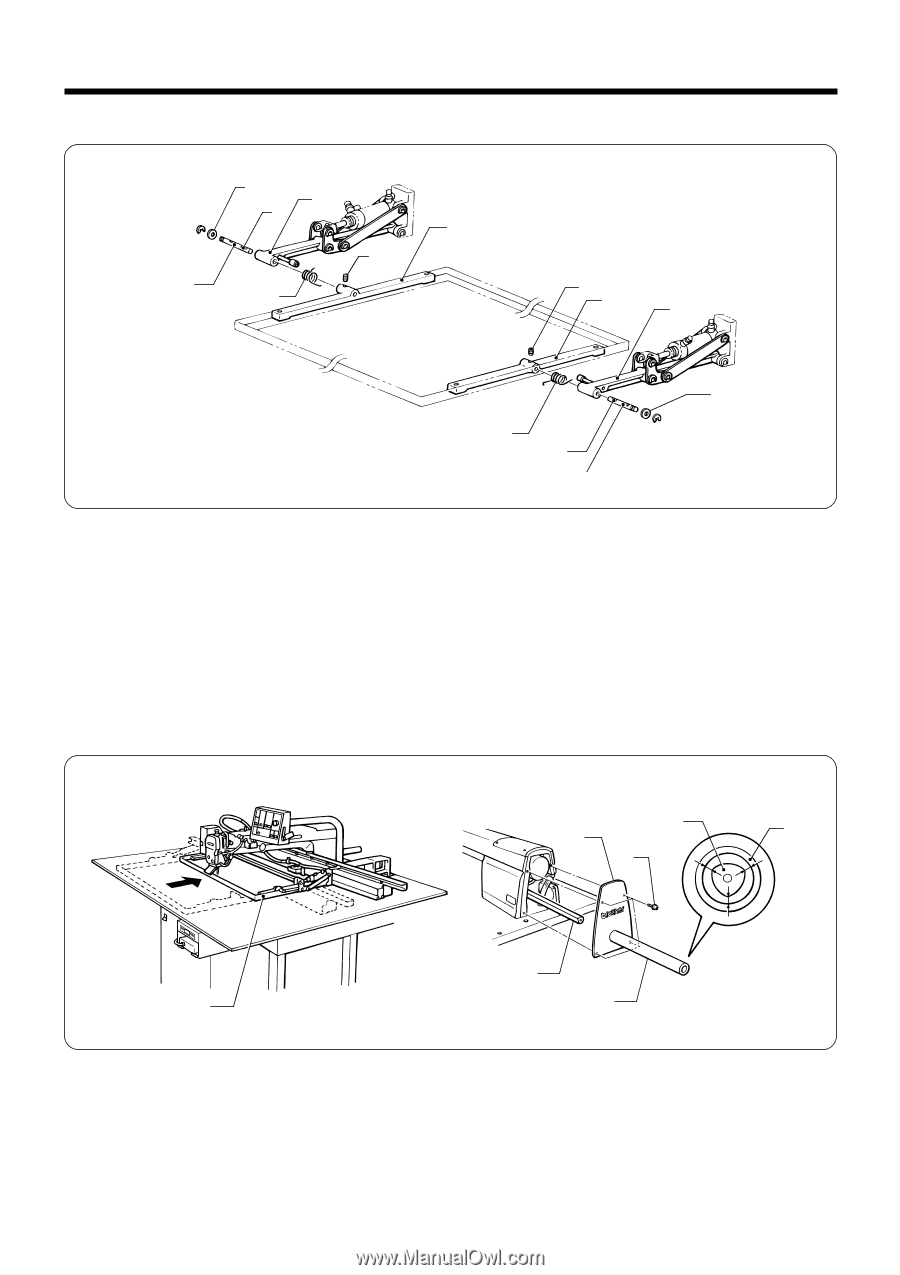

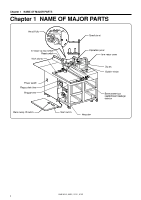

Chapter 3 INSTALLATION 4. Installing the work clamp hinge y u q w i t r i w q y e u t 1. Clamp hinge spring (R) e and hinge spring (L) r with the work clamp arm q and work clamp hinge w. 2. After placing the thrust washer y onto Y pulley shaft (A) t, insert Y pulley shaft (A) t into the work clamp arm q and work clamp hinge w. Note Insert Y pulley shaft (A) t into the hole of the work clamp hinge w so that the screw stop u is facing upward. 3. Secure the work clamp hinge w and Y pulley shaft (A) t with the set screw i. Note Make sure that the set screw i goes into the screw stop u of Y pulley shaft (A) t. 5. Installing the arm motor cover w t e r w q r 1. Move the feed mechanism q manually until it is as far into the machine as it will go. (The ball spline w should be extended fully toward the front when looking from behind the arm.) 2. Aligh the arm motor cover e with the rear of the arm so that there is even clearance between the tube section r and the ball spline w, and then secure with the accessory screws t. Note If noise is heard from the tubular section r of the arm motor cover e while the machine is operating, adjust the installation position of the arm motor cover e according to the procedure in step 2. above. BAS-364E, 366E, 370E, 375E 5