Craftsman 68496 Operation Manual - Page 2

Roebuck and Co., Dept. 817WA, Hoffman - staples

|

UPC - 077914036838

View all Craftsman 68496 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 2 highlights

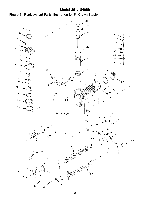

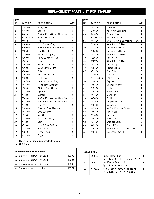

Warranty Safety Rules Operation Maintenance Troubleshooting Parts Illustration and List EspaSol 2 2 2-4 4 5 6-7 8-11 FULL ONE YEAR WARRANTY ON CRAFTSMAN AIR-DRIVE TOOLS If this Craftsman air-drive tool fails due to a defect in material or workmanship within one full year from the date of purchase, return it to the nearest Sears Service Center in the United States, and Sears will repair it free of charge. If this air-drive tool is used for commercial purposes, this warranty applies for only 90 days from the date of purchase. This warranty gives you specific legal rights and you may also have other rights which vary from state to state. Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179 • Air tool operators and all others in work area should always wear safety goggles complying with United States ANSI Z87.1 to prevent eye injury from fasteners and flying debris when loading, operating or unloading this tool. • Never exceed operating pressure of 100 PSI. • Always keep hands and body away from the fastener dis- charge area when air supply is connected to tool. • Always disconnect tool from air supply when servicing or adjusting tool and when tool is not in use. • Do not operate when nose of tool is not in contact with work. • Never load the tool until you are ready to use it. • Never depress tool trigger when loading. • Always load with nose of tool pointing away from you and others. • Never point tool at yourself or others. • Never carry tool with trigger depressed. • Do not use oxygen, combustible gas or high pressure compressed gas as the air supply for the tool. • Always use tool at safe distance from other people in work area. • Do not attempt to discharge fastener into hard or brittle materials such as concrete, steel or tile. • Do not connect female quick-disconnect coupling to tool side of air line. • Connect male, free-flow nipple to tool side of air line so that tool is depressurized when hose is disconnected. • Do not use a hose swivel with this tool. • Use Sears recommended fasteners only. DESCRIPTION The Craftsman '_" Crown Stapler drives _" crown, 18 gauge staples from % to 1" long. Oilless design eliminates daily oiling and oil stains on workpiece. Die cast aluminum body with textured grip minimizes operator fatigue. Large capacity, top loading magazine with positive quick action latch makes loading easy. Safety feature disables tool unless contact trip is pressed against workpiece. Tapered nosepiece provides operator with greater visibility for precise fastener placement. Rigid nosepiece reduces jamming. The '¼" Crown Stapler is excellent for furniture making, upholstery, cabinetry and picture framing. SPECIFICATIONS Capacity 120 staples Staple crown width '_" Staple lengths 3/8to 1" Staple size 18 gauge (.049 x .040") Operating pressure 60-100 PSI Air inlet '_" N.P.T. Length Height Width 9_ '' 7'_ '' 2_ '' Weight 2.05 Ibs. STAPLES 18333 18334 18336 18371 '_" crown, _/2"long '/4" crown, 3/4"long '/4" crown, 7/8"long '/_" crown, 1" long AIR SUPPLY LINE Refer to Figure 1 (page 3). ° The air tool operates on compressed air at pressures from 60 to 100 PSI. ° Never exceed maximum pressure. Air Delivery Required: 0.47 SCFM @ 90 PSI (30 shots per minute). WARNING: Keep hands and body away from discharge area of tool when connecting air supply. Always disconnect tool from air supply when servicing or adjusting tool and when tool is not in use. ° Air operated tools require clean, dry, compressed air to ensure top performance, low maintenance and long life. ° Dirt and abrasive materials present in all air lines will damage tool O-rings, valves and cylinders. ° Moisture will reduce tool performance and life if not removed from compressed air. ° A filter-regulator system is required and should be located as close to tool as possible (see Figure 1, page 3). A distance of less than 15 feet is recommended. ° Keep air filter clean. A dirty filter will reduce the air pressure to the tool causing a reduction in power and efficiency. ° The air supply system must be able to provide air pressure of 60 to 100 pounds per square inch at tool. 2