Dell PowerVault 132T LTO Dell PowerVault DLT, VS, and SDLT Media Handbook V - Page 18

This amount of stress will pull the tape media further, spring-loaded cartridge hub on impact.

|

View all Dell PowerVault 132T LTO manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

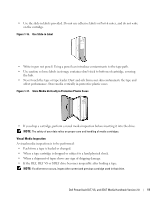

www.dell.com | support.dell.com Figure 1-27. SDLT Cartridge - Bent media buckle SDLT Media When inspecting an SDLT media cartridge, refer to the following diagrams to check the leader buckles on the media. Figure 1-28 shows a good cartridge. Note the plastic hooks resting on the cartridge rails and bar parallel to the cartridge. Figure 1-28. Good SDLT Leader Buckles bar hooks Tests have shown that dropping the media can cause an excessive amount of stress to the spring-loaded cartridge hub on impact. This amount of stress will pull the tape media further into the media cartridge and bend the leader buckles. See Figure 1-29 to identify bent-in leader buckles. Note that the plastic hooks are bent inward and not resting on the cartridge wall. Also the bar is not parallel to the cartridge. It is usually the HUB side of the cartridge that gets more pulled. 16 Dell PowerVault DLT, VS, and SDLT Media Handbook Version 2.0