11

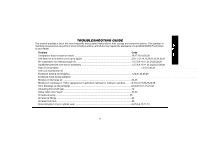

TROUBLESHOOTING GUIDE

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The operator or

maintenance personnel can perform some corrective actions, and others may require the assistance of a qualified D

E

WALT technician

or your dealer.

Problem

Code

Compressor does not start or restart

..............................................................................................

16,17,18,19,20,36

Unit does not or is slow to come up to speed

................................................................................

3,8,11,12,14,15,20,21,22,24,25,31

Air compressor not making enough air

............................................................................................

1,3,7,8,9,10,11,21,24,25,28,29

Insufficient pressure at air tool or accessory

..................................................................................

1,3,7,8,9,10,11,21,24,25,27,28,29

High oil consumption.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1,12,15,30,32

Unit runs excessively hot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Excessive starting and stopping

......................................................................................................

7,20,21,24,25,29

Excessive noise during operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moisture in discharge air

..................................................................................................................

34,35

Moisture in crankcase or "milky" appearance in petroleum lubricant or rusting in cylinders

..........

6,7,9,10,15,25,26,33,35

Oil in discharge air (oil pumping)

....................................................................................................

2,6,8,9,10,11,15,31,32

Oil leaking from shaft seal

................................................................................................................

12

Safety relief valve "pops"

................................................................................................................

22,23

Air leaks at pump

............................................................................................................................

25

Air leaks at fittings

............................................................................................................................

25

Air leaks from tank

..........................................................................................................................

26

Abnormal piston ring or cylinder wear

............................................................................................

2,4,5,6,9,10,11,13