Fluke TiR1 Fluke TiR Thermal Imager Datasheet - Page 8

Thermal imaging, terminology explained - infrared camera

|

View all Fluke TiR1 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

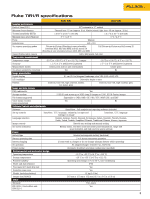

Thermal imaging terminology explained Palette-Color representation of the temperatures (temperature scale) in a displayed image. Certain color palettes meet personal preferences or optimize the image for different applications and/or problems. An example of the different palettes appear to the right. Sensor Size-Similar to digital cameras the sensor size describes the amount of displayed points per image of a thermal imager. A sensor size of 160 x 120 captures and displays more than 19,000 measurement points with each measurement. If the imager is fully radiometric then it also truly measures and stores all captured points with the image. Field of view (FOV)-Indicates what the thermal imager sees or measures at a given moment. The combination of the Field Of View specification and the distance to the measured object determines which surface or part of an object will be measured as a total. A thermal imager with a FOV of 23° x 17° (20 m), F=0.8 lens) can detect an object that is 6 m (20 ft) wide by 4.5 m(15 ft) high. This same imager can infer a temperature measurement of a smaller section within that object of 3.8 cm X 3.8 cm (1.5 in x 1.5 in). A FOV calculator on www.fluke. com/FOV helps you calculate the measurement surface at various distances to the object. Thermal sensitivity- Indicates what the smallest temperature difference is which can be measured/displayed in an image. It basically is the maximum resolution of the image and is referred to as NETD (noise equivalent temperature difference). Emissivity adjustment-All surfaces emit infrared energy or heat. The level of emission varies much per surface and is described with the term emissivity. Painted coatings and materials usually have a high emissivity while polished aluminum has a low emissivity. Visit www.fluke.com/emissivity for a table with emissivities for different materials. If you perform qualitative inspections with the imager (most applications) then emissivity does not have to be adjusted. To measure the temperature of a material accurately it will be necessary to adjust for the material's emissivity in specific applications. Span-The set of temperature values that can be measured within a preset range. Adjusting the span allows you to see more subtle temperature gradients (or contrast) in a captured image. When the span is optimized the imager shows 256 different shades of color in an image. Ironbow Blue-red High contrast Amber Hot metal Grey 8