GE DSKS433EBWW Installation Instructions - Page 4

Alcove Or Closet, Installation - parts

|

UPC - 084691046387

View all GE DSKS433EBWW manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

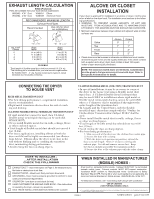

EXHAUST LENGTH CALCULATION RIGID (Preferred) Parts are available from your local service organization: WX8X63 4"X1' Duct WX8X51 Elbow WX8X64 4"X2' Duct WX8X59 Aluminum hood RECOMMENDED MAXIMUM LENGTH Exhaust Hood Types Recommended Use only for short run installations 4" DIA. 4" DIA. No. of 90º Elbows 0 1 2 3 4" Rigid Metal 14 m (46 ft) 11 m (38 ft) 9 m (31 ft) 7 m (24 ft) 2-1/2" Rigid Metal 11 m (37 ft) 9 m (30 ft) 6.5 m (22 ft) 4.5 m (15 ft) FLEXIBLE Total length of flexible metal duct shall not exceed 8 ft (2.4 m). The following kit is available from you local service organization: Kit WX08X10077 - 4" dia. flexible metal (semi-rigid) UL-listed transition duct (includes 2 elbows). ALCOVE OR CLOSET INSTALLATION If your dryer is approved for installation in an alcove or closet, it will be stated on a label on the dryer back. The installation must conform to the following specifications; WARNING: TO PREVENT LARGE AMOUNTS OF LINT AND MOISTURE FROM ACCUMULATING AND TO MAINTAIN DRYER EFFICIENCY, THIS MACHINE MUST BE EXHAUSTED OUTDOORS. Minimum clearances between dryer cabinet and adjacent walls or other surfaces are: Sides Alcove Closet 0" 1" Top 1" 1" Front - 3" Rear 3" 3" Closet doors must be louvered or otherwise ventilated and must contain at least 60 square inches of area equally distributed. If this closet contains both a washer and a dryer, doors must contain at least 120 square inches of open area equally distributed. NOTE: The clearances stated above are minimums. Consideration must be given to the type accessory kit used with dryer. Refer to the specific kit instruction for details. CONNECTING THE DRYER TO HOUSE VENT RIGID METAL TRANSITION DUCT • For best drying performance, a rigid metal transition duct is recommended. • Rigid metal transitions ducts reduce the risk of crushing and kinking. UL-LISTED FLEXIBLE METAL (SEMI-RIGID) TRANSITION DUCT • If rigid metal duct cannot be used, then UL-listed flexible metal (semi-rigid) ducting can be used (Kit WX08X10077). • Never install flexible metal duct in walls, ceilings, floors or other enclosed spaces. • Total length of flexible metal duct should not exceed 8 feet (2.4m). • For many applications, installing elbows at both the dryer and the wall is highly recommended (see illustrations below). Elbows allow the dryer to sit close to the wall without kinking and or crushing the transition duct, maximizing drying performance. • Avoid resting the duct on sharp objects. UL-LISTED FLEXIBLE METAL (FOIL-TYPE) TRANSITION DUCT • In special installations, it may be necessary to connect the dryer to the house vent using a flexible metal (foiltype) duct. A UL-listed flexible metal (foil-type)duct may be used ONLY in installations where rigid metal or flexible metal (semi-rigid) ducting cannot be used AND where a 4" diameter can be maintained throughout the entire length of the transition duct. • In Canada and the United States, only the flexible metal(foil-type) ducts that comply with the "Outline for Clothes Dryer Transition Duct Subject 2158A" shall be used. • Never install flexible metal duct in walls, ceilings, floors or other enclosed spaces. • Total length of flexible metal duct should not exceed 8 feet (2.4m). • Avoid resting the duct on sharp objects. • For best drying performance: 1. Slide one end of the duct over the clothes dryer outlet pipe. 2. Secure the duct with a clamp. 3. With the dryer in its permanent position, extend the duct to its full length. Allow 2" of duct to overlap the exhaust pipe. Cut off and remove excess duct. Keep the duct as straight as possible for maximum airflow. 4. Secure the duct to the exhaust pipe with the other clamp. NOTE TO INSTALLER ...AFTER INSTALLATION CHECK THE FOLLOWING EXHAUST DUCT - must meet specs on Page 3. No excessive turns. No kinks or obstructions to air flow. EXHAUST HOOD - should work freely and open downward. GROUNDING - Dryer must be properly grounded to conform to local codes and ordinance requirements. OPERATION - turn dryer on and check for heat. HAND CUSTOMER THE USE AND CARE BOOK - Give instructions on operating the dryer - answer any questions. GIVE THESE INSTALLATION INSTRUCTIONS to the customer. WHEN INSTALLED IN MANUFACTURED (MOBILE) HOMES - Dryer must be exhausted to the outside. Exhaust MUST NOT be terminated beneath mobile home. Exhaust material MUST NOT support combustion. Installation MUST conform to Manufactured Home Construction & Safety Standard, Title 24 CFR, Part 32-80 or when such standard is not applicable, the American National Standard of Mobile Homes, ANSI/NFRA No. 501B-1977. For electrical connection, see "Connecting dryer using 4 wire connection". USE OF CASTERS (120V PORTABLE MODELS ONLY) For a portable installation screw casters into the holes on the bottom of the dryer. Refer to the "Installation Instructions for caster assembly" sheet to install casters. PAGE 4 322B3166P001 pub # 31-16233