HP DL320 hp ProLiant DL320 generation 2 server high-density deployment - Page 3

power and thermal budgeting - quickspecs

|

UPC - 829160513218

View all HP DL320 manuals

Add to My Manuals

Save this manual to your list of manuals |

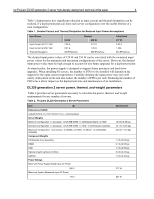

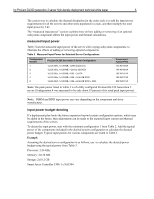

Page 3 highlights

hp ProLiant DL320 generation 2 server high-density deployment technical white paper 3 IMPORTANT: In this document, derating the input power budget means using less than the maximum rated input power values for the power supply. HP strongly recommends using the installation planner to ensure that the derated power budget will satisfy all the installation requirements, including future upgrade plans. Refer to the HP ProLiant DL320 Generation 2 Server QuickSpecs for detailed specifications and options for this server. power and thermal budgeting accounting for server input power Note: In this document, derating the input power budget means not using the maximum rated input power values for the power supply. HP strongly recommends using the installation planner to ensure that the derated power budget will satisfy all the installation requirements, including future upgrade plans. All power requirement discussions in this document are based on the input power of the server, since this number has direct impact in planning for the PDU selection and the facility power source. One of the following methods can be used to account for input power in the facility power distribution planning: • Use the maximum rated input power of 277 W. • Use the derated input power, which can be calculated by subtracting the power budgets of uninstalled optional components from the rated input power. • Use the allocated input power, which can be calculated by dividing the maximum power of a PDU by the number of servers. This calculated power should be at least 250 W to support all the optional components initially released with the server. The power budgets of optional components, referred to in the following sections, were derived from the system input power of a set of selectively measured server configurations. These configurations measured range from a basic low-end configuration to a fully populated high-end configuration. Since the input power values used in an installation might vary depending on the software applications, the information provided in this section should be used as a guideline only. The server power supply is designed to support future upgrades of processors, DIMMs, and hard drives. As such, the power supply output power is rated at 180 W. Assuming the power supply efficiency of 65 percent (including the Power Factor Correction), the power supply input power is rated at 277 W. This input power value may be used in planning for the power source implementation and facility cooling requirements. In some cases the input power requirement for each server might be desired to be lower than 277 W. The input power requirement might be lowered in the following instances: • To minimize the number of PDUs, that is, the number of facility power feed lines, required for each rack. • To match the rack current requirements with the existing facility branch circuit breakers. • To match the rack cooling requirements with the existing facility environment.