HP Designjet L26100 HP Designjet L26500 / L26100 / L28500 printer series - Add - Page 2

L26500 / L26100 - designjet l26500 printer

|

View all HP Designjet L26100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 2 highlights

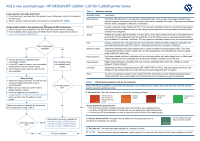

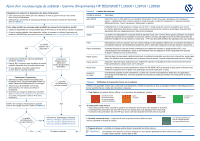

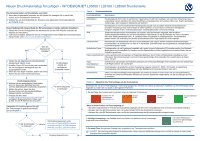

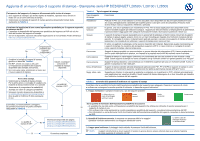

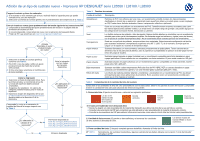

Add a new substrate type - HP DESIGNJET L26500 / L26100 / L28500 printer series Load substrate and align printheads 1. If the substrate is narrower than the spindle, move it leftwards so that it is centered in the print zone. 2. Select a generic substrate family at the printer's front panel from Table 1. Table 1 Substrate families Substrate family Description Self-adhesive PVC films with adhesive on one side and a detachable liner. There are two main types classified by application purpose: calendered (for flat surfaces) and cast (for complex 3D curves). They may have different finishes: white, transparent, reflective or perforated. Create and/or install a new media preset following the RIP instructions 1. Check media preset availability in the RIP and/or substrate vendor's website. 2. If not available, check again using the Media Finder search application located at www.hp.com/go/latexmediafinder. Banner Textile Usually a polyester mesh coated with PVC. There are also recyclable versions to cover the same applications (green banners). Banners have a wide range of grammage and can be grouped into frontlit, backlit, and block-out categories. Textiles are usually made of polyester or cotton yarns. Some open textiles come with a removable liner to prevent the ink from passing through the substrate. Very stiff textiles (such as canvases) should preferably be loaded as "Low-temp." substrate. The use of porous substrates without a liner is not recommended. Was media preset No available? Yes 1. Choose the generic substrate family according to Table 1. 2. In the RIP, create a copy or use an available media preset from the chosen family. 3. If you create a copy, select a name for the new substrate. Start printing 1. Select the initial print mode. For the first trial, a 12-pass bidirectional print mode is recommended. 2. Make sure you reset your print mode to default category values. 3. Print the diagnostic plot available in ip-addr/hp/device/webAccess/images/new.tif where ip-addr is the IP address of your printer. Start printing using the available print modes Is the print quality OK? Film Synthetic paper Paper-aqueous Paper-solvent Low-temp. Mesh Usually a polyester film, although there are other materials. Select this family setting for substrates that can resist temperatures over 95°C (200°F), otherwise load them as "Low-temp." substrate. Substrates manufactured using synthetic resins, mainly extruded from polypropylene (PP). They have characteristics similar to those of plastic film, but their appearance and properties are similar to regular paper made from wood pulp. Light paper-based (cellulose) substrates with a coating compatible with water-based inks, or offset paper. These substrates are not compatible with solvent inks. Weight is usually around 100 g/m². Paper-based (cellulose) substrates with a top coating compatible with solvent inks. Weight is usually between 120 and 200 g/m². Substrates sensitive to high temperatures (PP, HDPE, PET thin films), and paper-based (cellulose) substrates with top coating that have a high stiffness and grammage (200 g/m² or higher). An open and resistant polyester mesh coated with PVC and mainly used for building wrap applications. These substrates have a removable liner to prevent the ink from passing through the substrate. Table 2 Checking the quantity of ink on the substrate Check that the ink quantities in your preset are adequate. Look at the plot color patches and check that they have the right ink quantity using the guidelines below: 1. Too much ink: The patch shows one or more of the following problems: The last two or three scales of the plot look the same. Vertical bands Horizontal bands Coalescence grain Check (and correct if needed) the ink quantity No in the printed plot, using Table 2. If your preset has too much ink Yes You may have chosen a media preset that uses more ink than your substrate allows. Consult your RIP documentation to make sure you are applying the right media preset. Consult your RIP documentation on how to lower the total ink limits of the media preset. Is the print quality OK? Information resources available at: No www.hp.com/go/L26500/solutions www.hp.com/go/L26100/solutions www.hp.com/go/L28500/solutions Yes Process complete 2. Correct amount of ink: The patch has no defects and increasing amounts of ink result in increasing color density. The last scales of the plot show a smooth increase 3. Too little ink: The whole plot looks washed out. Increase ink limits. NOTE: Backlit and some fabrics substrates usually require to be used with the "High Ink Limit" option enabled in the RIP.