HP Integrity Superdome 2 8-socket LIFT-O-FLEX® 17000 SP 400 Manual - Page 10

Directional wheel locks, Troubleshooting, Symptom, Action

|

View all HP Integrity Superdome 2 8-socket manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

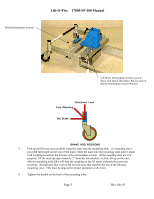

Lift-O-Flex 17000 SP 400 Manual Directional wheel locks When moving a heavy load, it is both easier and safer if you use the directional wheel locks by moving the red bar into the upper position. Both back wheels are now locked in a straightforward position. This gives greater directional stability when moving heavy loads. Observe that it is especially important that a heavy load be kept as low and as centered on the end-effector as possible. 3.2 Troubleshooting The LIFT-O-FLEX has been designed to operate safely and effectively provided that maintenance procedures are followed according to the instruction manual. A guide for trouble shooting is provided as listed below should any problems arise. If the problem remains after referring to the troubleshooting guide below - contact RONI, LLC in Charlotte, NC. Symptom Action 1. The lifter does not run at all. A) Check the voltage of the battery (18 Volts). B) Inside the power package where the batteries are located is a 20-ampere fuse (T16L-250V). Check that it's intact and operable. C) Check that the connections to the battery charger have been connected properly during recharge. D) Check that the maximum load is not exceeded. 2. The end-effector cannot be A) Check that the mast is positioned correctly in lowered or raised but the motor runs. the intermediate section. See above 2.1 Assembly. 3. The end-effector moves at a slower speed than normal A) See above 1A, 1C and 1D. 4. When lifting there is a strange sound and/or the lifter operates differently than usual. A) Attend the prescribed actions under 3.5 Maintenance Page 9 Rev July 01