HP ProLiant BL660c ISS Technology Focus, Number 13 - Page 2

HP EcoPOD 240a Environment Control System

|

View all HP ProLiant BL660c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 2 highlights

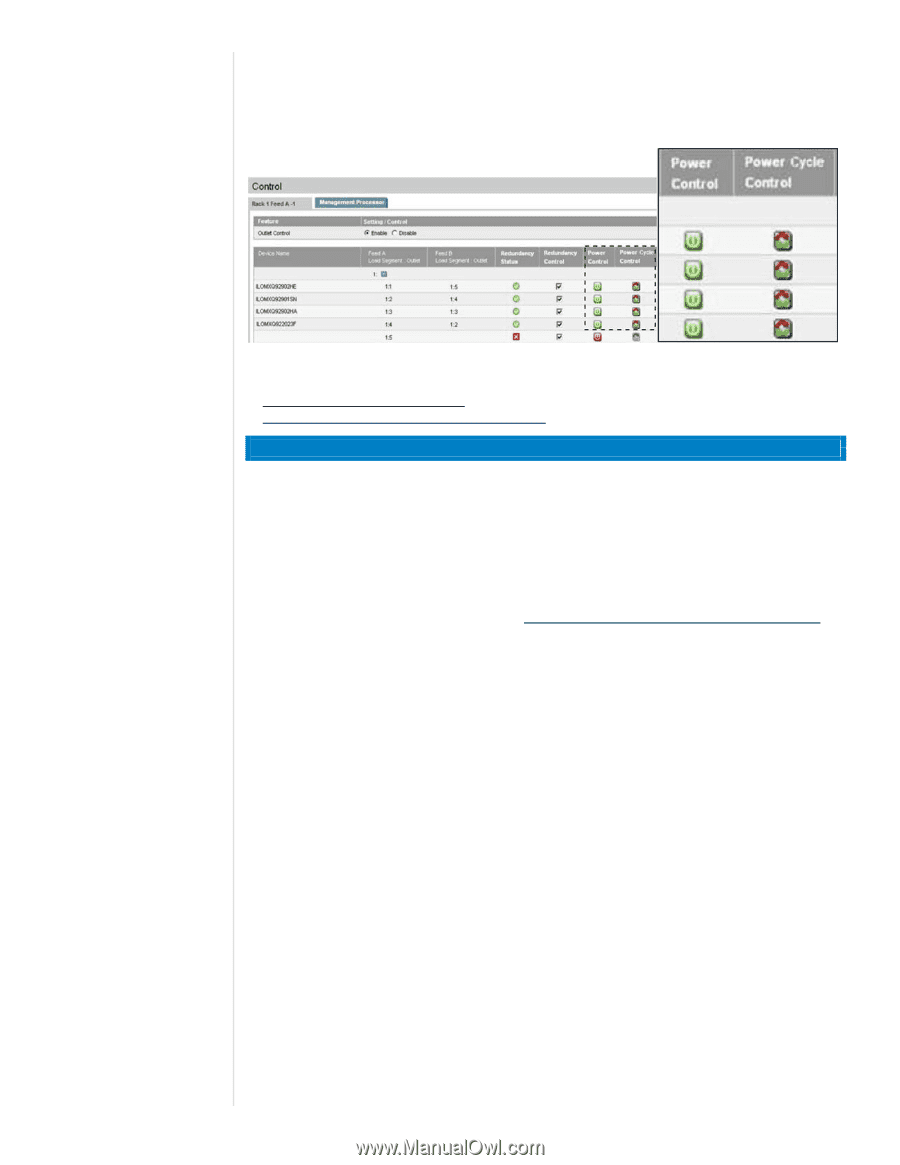

discovery process prompts the user to enter data into highlighted fields on the Device Assignment web page. See ―Additional resources‖ for links to more information about IPD. Figure 1: Control page of the Intelligent PDU Management GUI (partial screen) Additional resources » HP Intelligent Power Discovery web site » HP intelligent power infrastructure solutions technology brief HP EcoPOD 240a Environment Control System The HP Performance Optimized Data Center 240a (EcoPOD) is an extremely efficient, modular solution with integrated power, cooling, IT and facility management systems. The EcoPOD provides 1.2 MW of redundant power and cooling capacity for 2,200U of rack space, or 44 industry-standard 50U racks. It uses ambient (free) air to deliver a Power Usage Effectiveness (PUE) ratio as low as 1.05. It can also use free air or air from Direct Expansion (DX) air conditioning units to deliver the most efficient cooling possible. A previous ISS Technology Focus article, HP Performance Optimized Datacenter 240a, summarizes the EcoPOD's facilities, capabilities, and energy savings. This article describes its Environment Control System (ECS). It monitors, manages, and automates the EcoPOD's power, cooling, and safety systems. IT load monitoring The ECS uses an industrial-quality programmable logic controller (PLC). The PLC gathers IT power consumption data from HP Monitored Power Distribution Units (PDU), up to two per rack. Each PDU accepts 3-phase 415V power and outputs 240V to the rack. The PDU has an input-current monitor that measures the aggregate current draw on each power circuit. Administrators can view IT load data locally or remotely with an optional management module. Policy-based Adaptive Cooling The PLC checks environmental conditions inside and outside the EcoPOD. It also monitors temperature sensors in the EcoPOD's hot and cold aisles and humidity sensors in its optional humidifier. Users can define policy set points for Adaptive Cooling based on industry parameters- ASHRAE recommended, ASHRAE allowable, or HP allowable temperatures. Based on these environmental conditions and user-defined policies, the ECS selects the Adaptive Cooling mode that uses the least amount of energy: • Free air mode. Ambient air within a specified temperature and humidity range provides cooling. • DX (recirculation) mode. The DX units provide all of the cooling. Facilities management The ECS's powerful management software allows you to manage facilities locally and