HP Scitex FB6100 Printing Technologies - Page 25

Printhead Chip, Chip Holder, Electronics Package

|

View all HP Scitex FB6100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

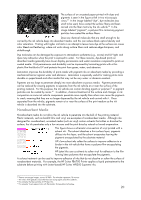

The HP Scitex X2 printhead is built with integrated circuit precision using silicon-based MEMS technologies.79 With its ability to produce features on a sub-micron scale, MEMS allows the shape of nozzles and ink channels to be optimized for an ink's physical properties for high performance drop ejection. MEMS produces drop generators with uniform characteristics across each printhead and from printhead to printhead, and this allows arrays of HP Scitex X2 printheads to deliver consistent drop volumes and velocities with high placement accuracy. The HP Scitex X2 printhead consists of three major subassemblies: the Printhead Chip, the Chip Holder, and the Electronics Package. These are seen in an exploded view in this figure. The Printhead Chip features a two-sided "side-shooter" design.80 64 nozzles, ink channels, and piezo actuators are formed on each side of a silicon chip. Each printhead delivers a single color of ink using 128 nozzles spaced at 100 nozzles per inch. A very thin, flexible glass plate is bonded to each side of the silicon chip to seal the ink channels. A piezo actuator and electrodes are deposited above each ink channel on the outside surface of the glass. This design completely isolates these electrical components from ink contact for long life and reliability. Each piezo actuator deflects the glass plate a fraction of a micron into its ink channel when a voltage pulse is applied. This ejects an ink droplet. The nominal drop velocity of 8 meters/sec is designed for precise dot placement at linear printing speeds up to 2 meters per second. The Chip Holder is the assembly that holds and aligns the Printhead Chip, locates and mounts the printhead in the printer, connects to the ink supply, provides an ink distribution manifold, and supports a flexcircuit that connects the Printhead Chip to the Electronics Package. With two ink ports, the ink supply can be designed so that ink flows across the manifold to purge bubbles. Two ports also minimize pressure drop at high ink flow rates: each HP Scitex X2 printhead can deliver up to 10 ml of ink per minute.81 The Electronics Package processes printhead control signals, regulates voltages, and drives the piezo actuators. It contains two identical electronic assemblies, one each for the top and bottom arrays of 64 nozzles. In an industrial inkjet printer with many printheads, convenient installation and maintenance of individual printheads is an important design consideration. The HP Scitex X2 printhead features mechanical, ink, and electrical connections that allow the printhead to be plugged into place and secured by two screws. Two mechanical locator pins provide better than 10-micron positioning accuracy without adjustment. Ink connections are made through ports sealed with an O-ring, so there are no ink tubes to attach and tighten. Electrical power and control signals come through a standard 26-pin connector. By design, HP Scitex X2 printheads offer high chemical resistance to industrial inkjet inks. This is because only silicon, glass and epoxy touch the ink, and the piezo actuators and electrodes are completely isolated from ink exposure. 79 MEMS is an acronym for MicroElectroMechanical System. MEMS photolithographic and chemical etching processes produce ink channels and nozzles in silicon. 80 "Side-shooter" means the ink drops are ejected in the plane of the chip. 81 Ink flow rate for comparative purposes based on the product of drop volume, drop ejection frequency, and number of nozzles. Actual ink delivery in operation depends on print mode, media, and other factors. 25