Hoover S5630 Manual - Page 4

Installation, How to use - central

|

View all Hoover S5630 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

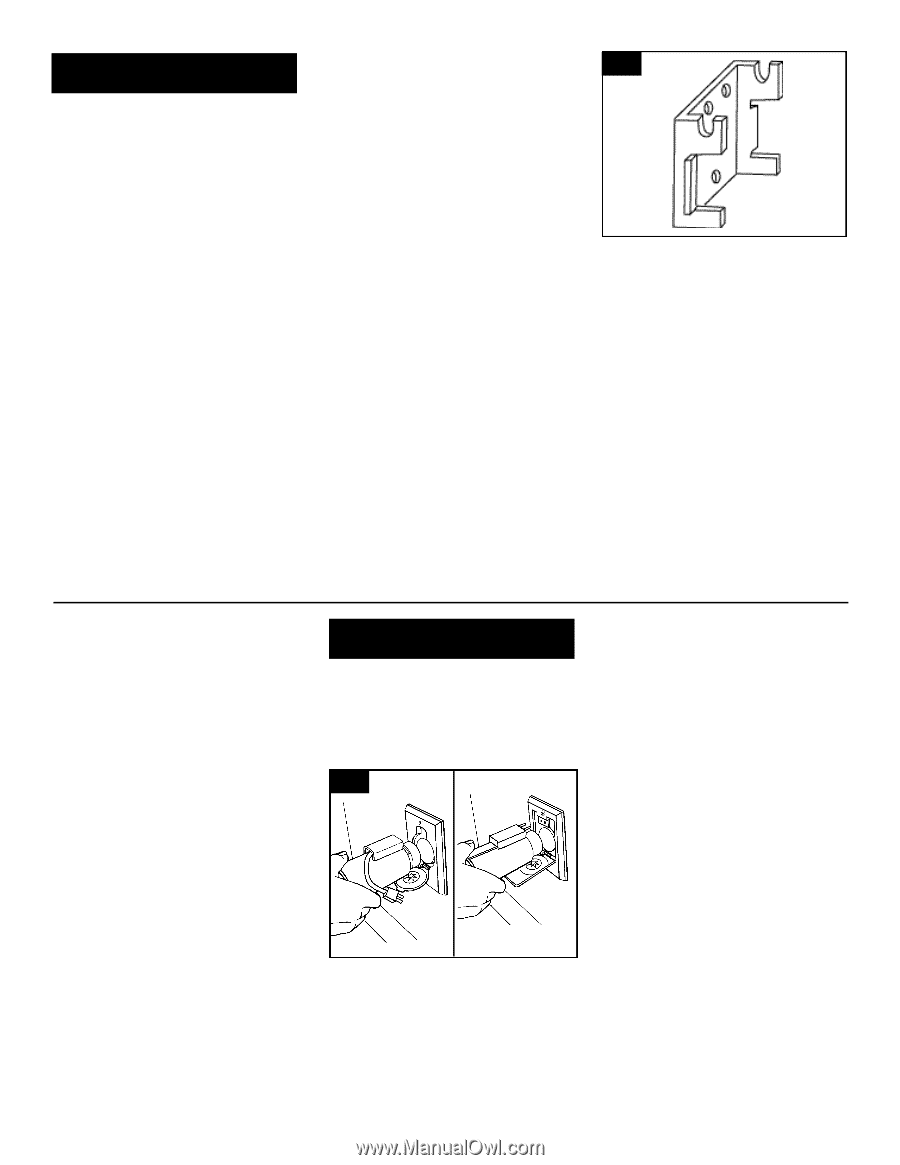

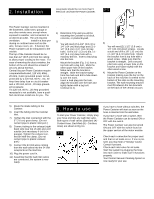

2. Installation Location for power canister The Power Canister can be mounted in the basement, utility room, garage or any other remote area, except where exposed to weather, and convenient to an electrical outlet. The unit requires ventilation. DO NOT install in a heat producing or confined area such as the attic, furnace room, etc. If desired, the Power Canister can be exhausted to the outside. The top of the Canister should be no less than 12" (30.5 cm) from the ceiling to allow proper cooling to the motor. For ease of removing the dust container, the bottom of the unit should be at least 6" (16 cm) above the floor. Central Vacuum Power Canisters require a separate/dedicated, 120 Volt, 60Hz., 20 Amp, 3 wire grounded power circuit, protected by a 120 Volt, 60 Hz., AC, 20 Amp time delay fuse or circuit breaker and a 120 Volt, 60 Hz., 20 Amp grounded receptacle. If a 120 volt, 60 Hz., 20 Amp grounded receptacle is not available, have a qualified electrician install one for you. The receptacle should be no more than 5 feet (152 cm) from the Power Canister. UNDER NO CIRCUMSTANCES SHOULD AN EXTENSION CORD BE USED WITH THIS CANISTER. Mounting the power canister 1) Determine if the wall you will be mounting the Canister to is block, concrete, or plaster/drywall. 2) Block or Concrete Wall You will need (2) 1-1/2" (3.8 cm) x 1/4" (.64 cm) lead plugs and (2) 11/2" (3.8 cm) x 1/4" (.64 cm) lag bolts. Drill a 1/2" (1.3 cm) dia. x 13/4" (4.4 cm) deep hole with a masonry drill bit. Insert a lead plug into the hole. Mount the bracket (Fig. 2-1) from a top hole with a lag bolt. Mark the other upper hole of the bracket. Make sure that the bracket is straight. Slide the bracket away from the mark and drill a hole directly over the mark. Insert a lead plug into the hole. Align the bracket over the hole and tightly fasten with a lag bolt. Continue to 4). 2-1 TOP MOUNTING BRACKET 3) Drywall or Plaster Wall You will need(2) 1-1/2" (3.8 cm) x 1/4" (.64 cm) wood screws. Locate a stud and drill a 1/8" (.32 cm) dia. x 1-3/4" (4.4 cm) pilot hole. Mount the bracket from a top hole with a wood screw. Make sure that the bracket is straight. Drill a second pilot hole using a lower hole on the bracket and fasten tightly with the other wood screw. 4) Mount the Power Canister on the bracket making sure the bar on the back of the machine is settled to the bottom of the slots on the mounting bracket. The wall mounting bracket must fit between the two brackets on the back of the central vacuum. 5) Route the intake tubing to the Canister. 6) Insert the tubing into the Canister inlet. 7) Tighten the inlet connection with the 3" (7.6 cm) gear clamp. (Do not cement pipe to plastic inlet port.) 8) Connect tubing to the exhaust (right hand side near top of unit) and vent outside (not necessary if unit is in garage). Tighten the exhaust connection with the clamp. (Do not cement pipe to plastic exhaust port.) 9) Connect the 24 Volt wires coming from the wall valves into the 24 Volt receptacle on the machine. 10) Plug the power cord in. 11) Assuming that the wall inlet valves are connected, the system is now ready. 3. How to use To start your Power Canister, simply plug your hose end into any wall inlet valve. Both types of wall valves (Standard (A) Corded Hose; Electrified (B) - Cordless Hose) are shown in Fig 3-1. 3-1 A B If you have a hose without switches, the Power Canister will start as soon as the hose is inserted into the wall valve. If you have a hose with a switch, then the Power Canister can be turned ON or OFF with the switch. The Power Canister can also be turned ON and OFF with the switch found on the upper section of the motor module. Check the System Check each connection for proper seal and that no air leaks occur. If one is present, you may hear a "hissing" sound. Correct if present. Check each inlet valve for air leaks. Start the system by plugging the hose into each valve to make sure it functions properly. Your Central Vacuum Cleaning System is now ready for your use. 4